Composite water-based emulsion sizing agent for carbon fibers, and preparation method for sizing agent

A water-based emulsion and composite technology, applied in the direction of carbon fiber, fiber type, fiber treatment, etc., can solve the problems of poor fatigue resistance and impact resistance, high cross-linking density, high surface energy, etc., and achieve stable glue content and uniform sizing amount , Cloth surface performance is excellent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

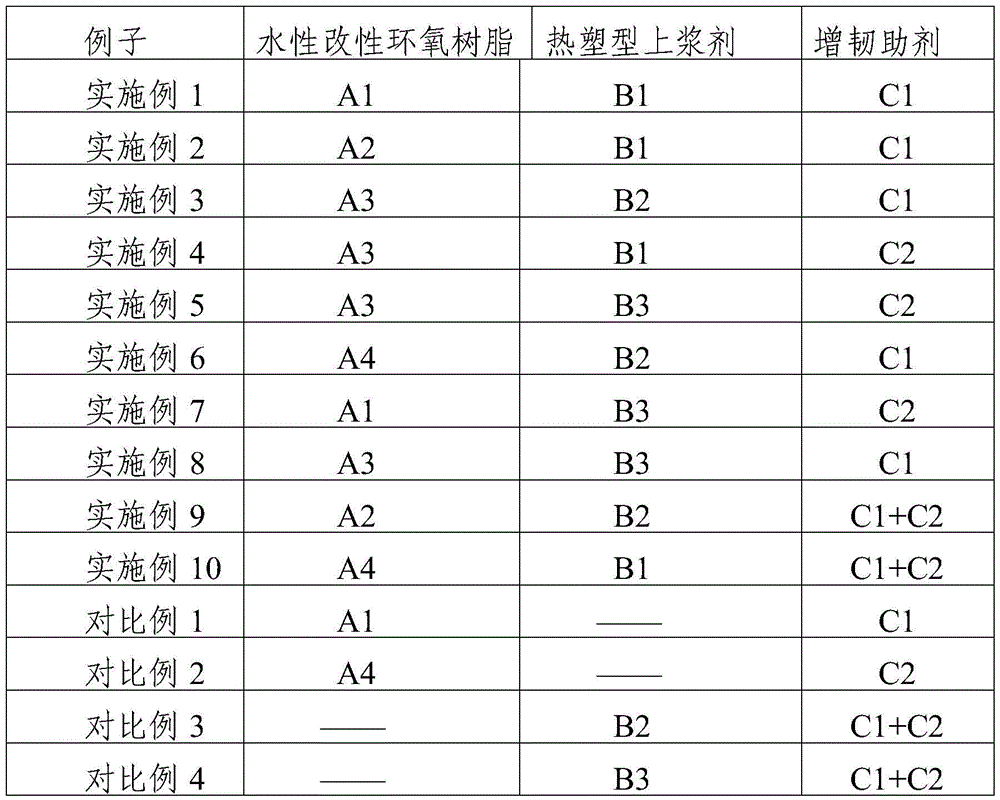

Examples

Embodiment 1

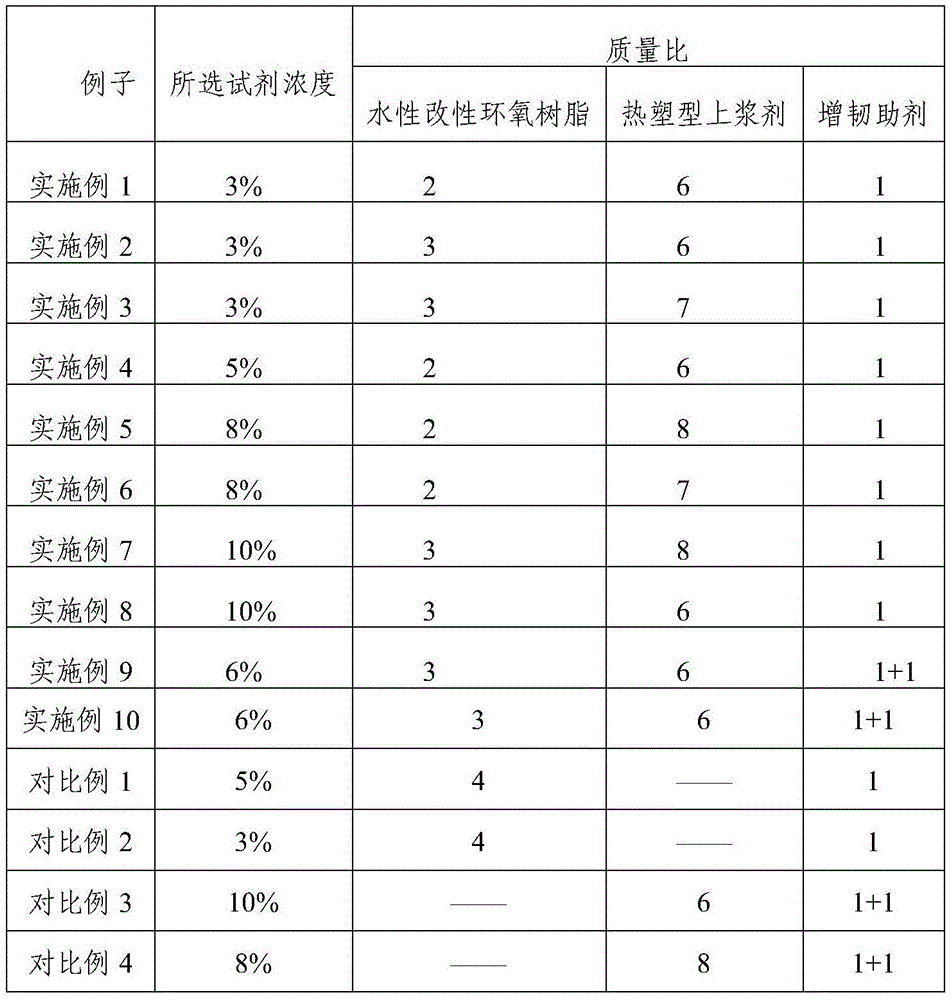

[0026] Dilute the water-based polyurethane modified epoxy resin emulsion A1, thermoplastic aliphatic saturated polyol B1, and toughening aid C1 into 3% water-based dilute emulsion, mix them uniformly according to the mass ratio of 2:6:1, stop stirring, A composite aqueous emulsion sizing agent for carbon fibers was obtained.

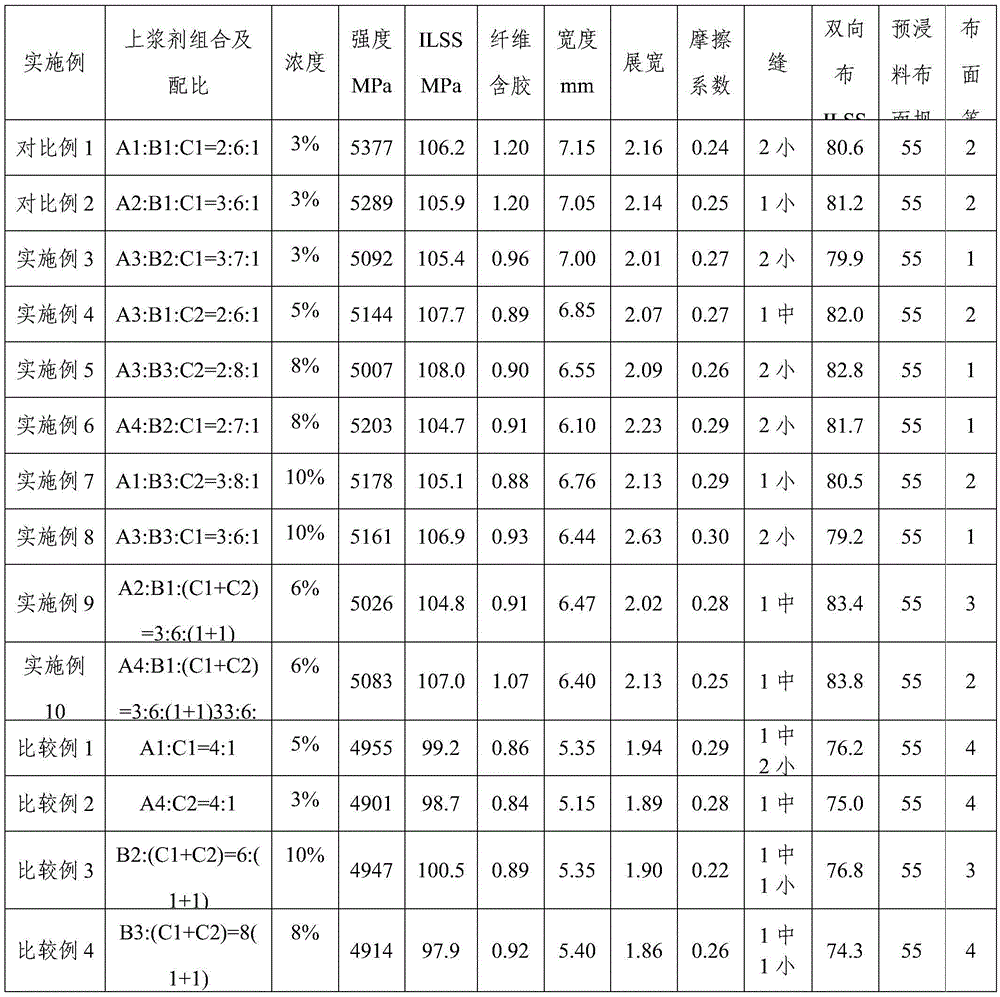

[0027] The mechanical properties of carbon fiber composite water-based emulsion sizing agent were tested.

Embodiment 2

[0029] Dilute the water-based polyurethane modified epoxy resin emulsion A2, thermoplastic aliphatic saturated polyol B1, and toughening aid C1 into 3% water-based dilute emulsion, mix them uniformly according to the mass ratio of 3:6:1, stop stirring, A composite aqueous emulsion sizing agent for carbon fibers was obtained.

[0030] The mechanical properties of carbon fiber composite water-based emulsion sizing agent were tested.

Embodiment 3

[0032] Dilute the water-based phenolic modified epoxy resin emulsion A3, thermoplastic unsaturated polyol B2, and toughening aid C1 into a 3% water-based dilute emulsion, mix them uniformly in a mass ratio of 3:7:1, and stop stirring to obtain Composite aqueous emulsion sizing agent for carbon fiber.

[0033] The mechanical properties of carbon fiber composite water-based emulsion sizing agent were tested.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com