Manufacture device and method for hemostatic gauze product with high stability and absorbability

A high-stability, hemostatic gauze technology, applied in absorbent pads, pharmaceutical formulations, textiles and papermaking, etc., can solve the problems of severe oxidation of cellulose degradation, unreasonable post-treatment methods, lack of mass transfer power, etc., to achieve non-selective Reduction of oxidation side reactions, optimization of post-treatment methods, and strict control of reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Adopt the preparation device of the hemostatic gauze product with high stability and high absorbability of the present invention, the fiber fineness of the raw cellulose fabric is 0.5 denier, and the fabric weight is 40g / m 2 .

[0055] The preparation process of using the device to prepare a highly stable and highly absorbable hemostatic gauze product comprises the following steps:

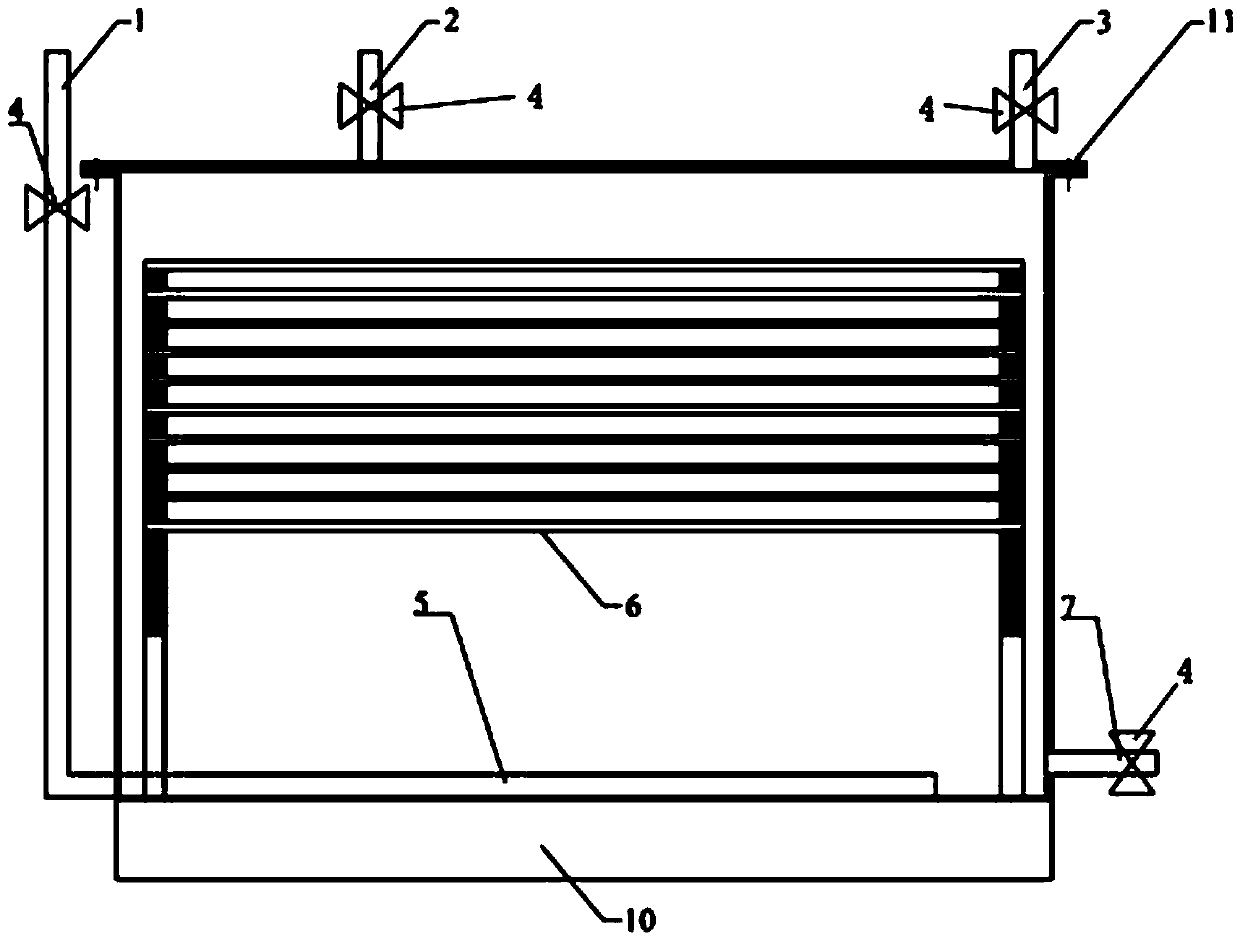

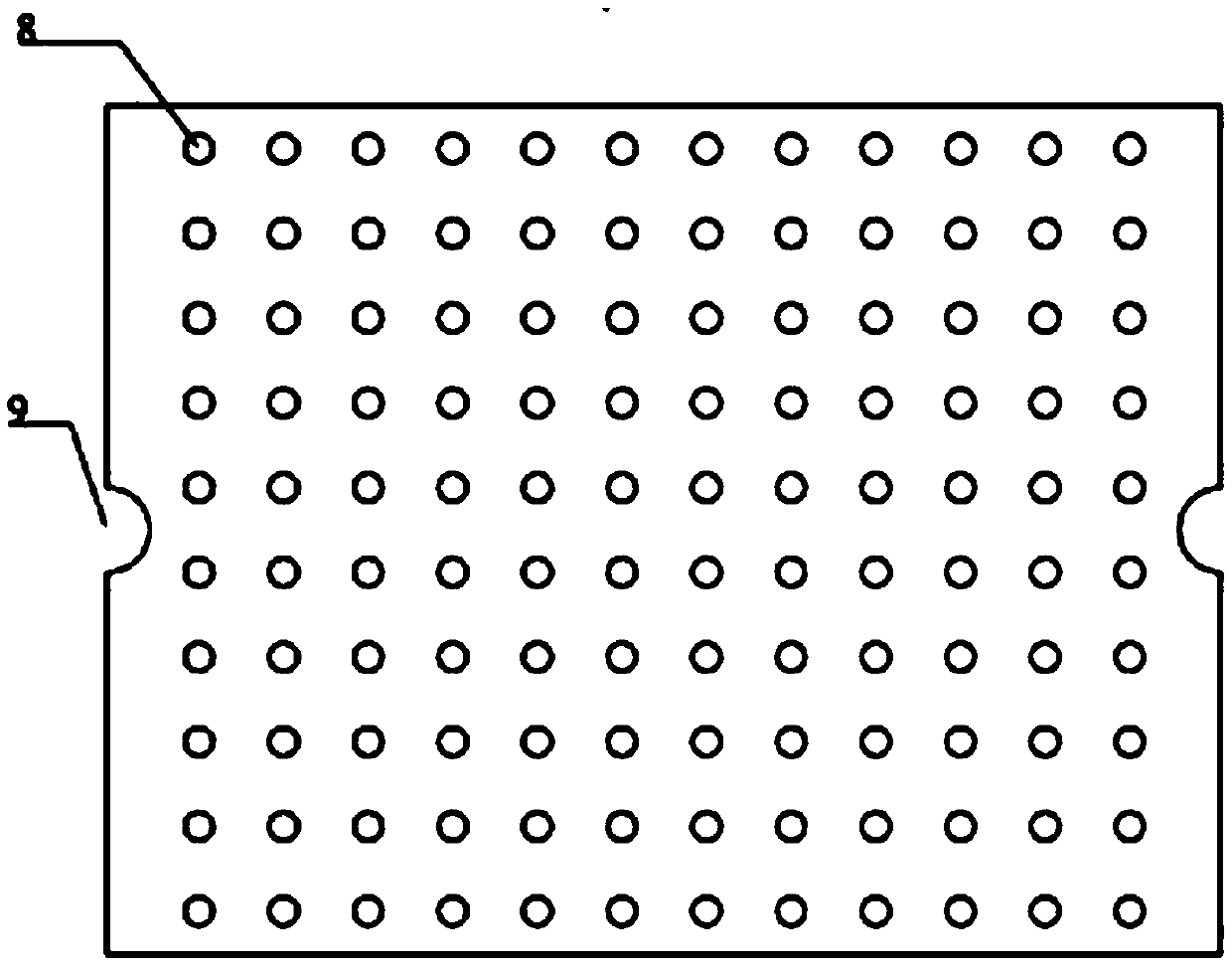

[0056] Put cellulose fabric 400g on this stainless steel plate 6.

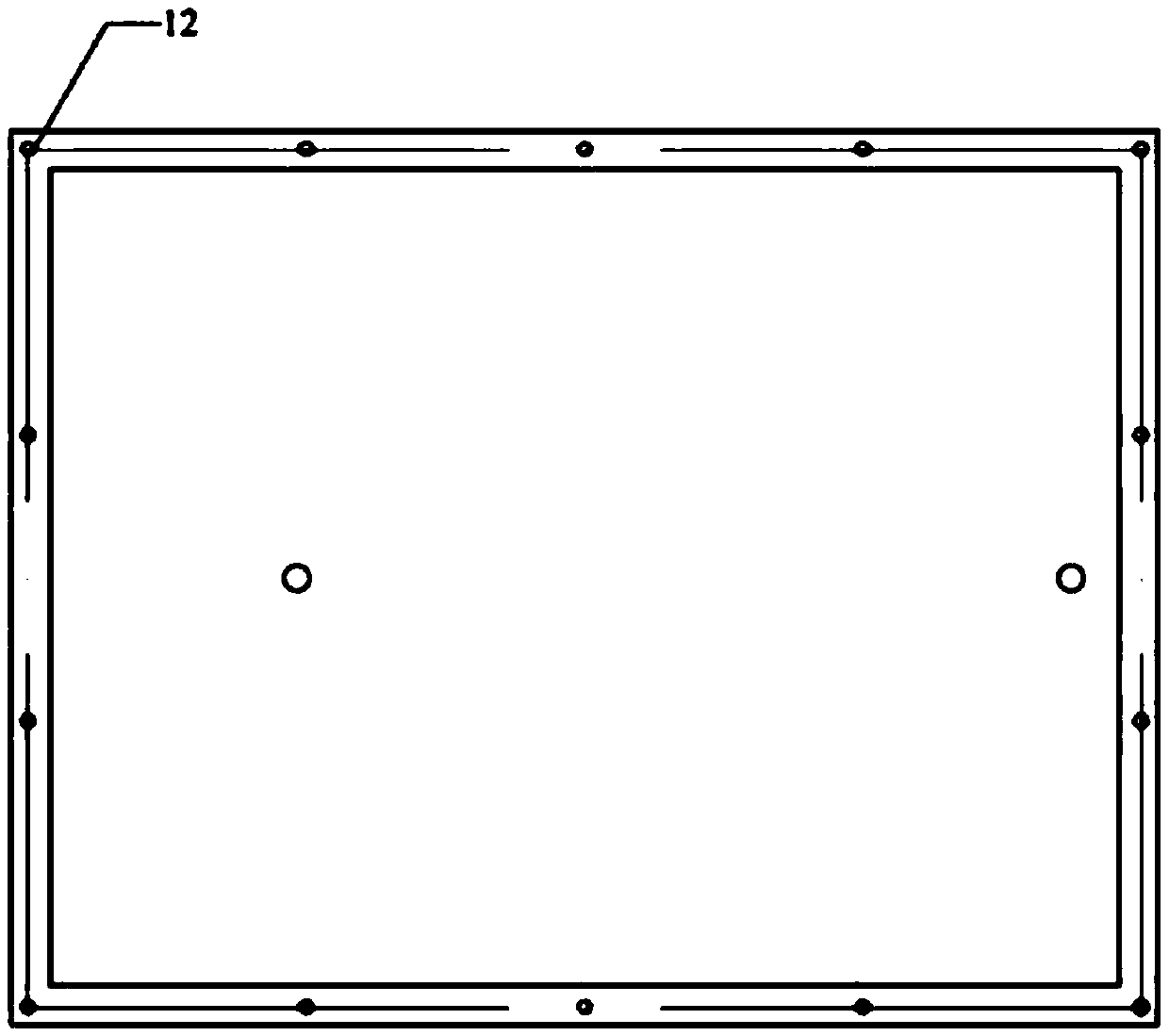

[0057] Put the stainless steel plates 6 into the tank body, stack them layer by layer, cover the tank cover, put a polytetrafluoro material gasket 11 between the cover and the tank body for sealing, and tighten the sealing nut 12.

[0058] Open the valve 4 of the feed pipe 1 and the gas outlet 3, and connect the gas outlet 3 to the exhaust gas absorption device. Add 0.5% dilute sodium hydroxide solution to the designated position to completely submerge all cellulose fabrics.

[0059] Ultrasound for 2 hours to obtain cell...

Embodiment 2

[0074] Adopt the preparation device of the hemostatic gauze product with high stability and high absorbability of the present invention, the fiber fineness of the raw cellulose fabric is 2 deniers, and the basis weight of the fabric is 200g / m2.

[0075] The preparation process of using the device to prepare a highly stable and highly absorbable hemostatic gauze product comprises the following steps:

[0076] 1000 g of cellulose fabric was placed on this reaction apparatus.

[0077] Put the stainless steel plate 6 into the tank body, stack it layer by layer, cover the tank cover, place a polytetrafluoro material gasket 11 between the cover and the tank body for sealing, and tighten the sealing nut 12.

[0078] Open the valve 4 of the feed pipe 1 and the gas outlet 3, and connect the gas outlet 3 to the exhaust gas absorption device. Add 1% dilute sodium hydroxide solution to the designated position to completely submerge all cellulose fabrics.

[0079] Ultrasound for 1 hour t...

Embodiment 3

[0094] Adopt the preparation device of the hemostatic gauze product with high stability and high absorbability of the present invention, the fiber fineness of the raw cellulose fabric is 5 deniers, and the fabric weight is 500g / m 2 .

[0095] The preparation process of using the device to prepare a highly stable and highly absorbable hemostatic gauze product comprises the following steps:

[0096] 1000 g of cellulose fabric was placed on this reaction apparatus.

[0097] Put the stainless steel plates 6 into the tank body, stack them layer by layer, cover the tank cover, place a polytetrafluoro material gasket 11 between the cover and the tank body for sealing, and tighten the sealing nut 12.

[0098] Open the valve 4 of the feed pipe 1 and the gas outlet 3, and connect the gas outlet 3 to the exhaust gas absorption device. Add 5% dilute sodium hydroxide solution to the designated position to completely submerge all cellulose fabrics.

[0099] Ultrasound for 0.5 hours to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com