Filtering medium for removing ibuprofen and clofibric acid in drinking water, filter element and preparation method

A technology of filter medium and chlorofibric acid, applied in chemical instruments and methods, other chemical processes, water/sewage treatment, etc., can solve the problems of complicated operation, high cost, secondary pollution, etc., and achieve high removal rate and simple method. , the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

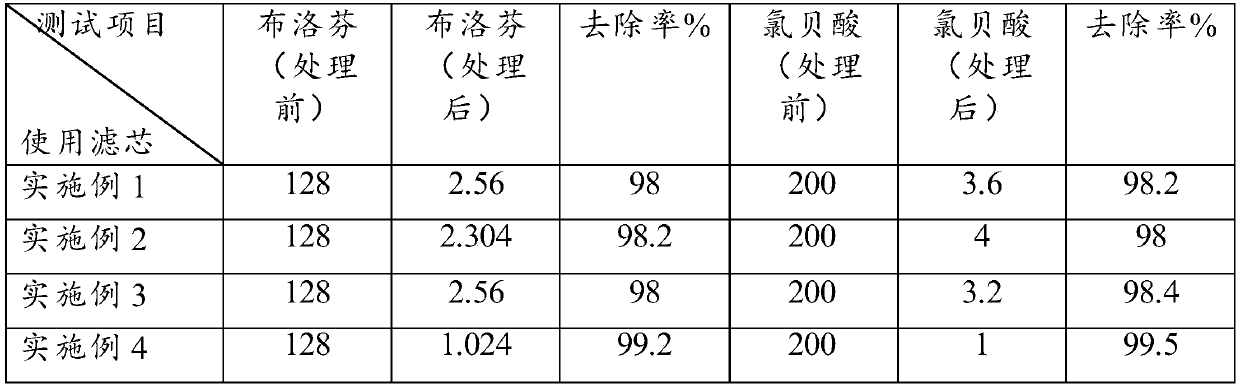

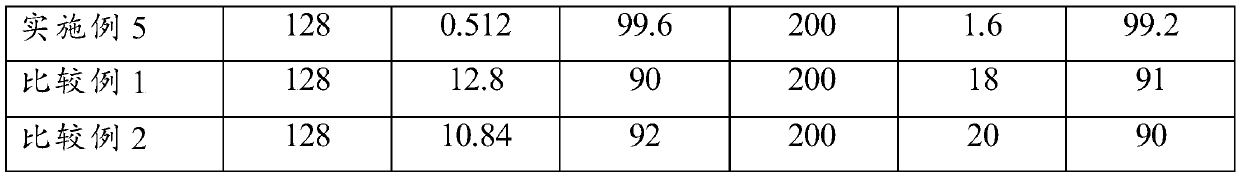

Examples

preparation example Construction

[0020] A preparation method for removing ibuprofen and clofibrate in drinking water, characterized in that it comprises the following steps:

[0021] a) mixing ultra-high molecular weight polyethylene powder, activated carbon powder, attapulgite powder, sepiolite powder and pore-forming agent to obtain a mixture, the ultra-high molecular weight polyethylene powder, activated carbon powder, attapulgite powder, sepiolite powder and foam The weight ratio of the pore agent is 200~300:50~100:100~200:100~200:50~100;

[0022] b) pressing, sintering and cooling the mixture obtained in step a) in a mould;

[0023] The pressing pressure is 0.4MPa-1Mpa; the sintering temperature is 200°C-245°C; the sintering time is 90-150min; and the cooling temperature is 40°C-60°C.

[0024] The present invention first mixes ultra-high molecular weight polyethylene powder, activated carbon powder, attapulgite powder, sepiolite powder and a pore-forming agent to obtain a mixture. The ultra-high molecul...

Embodiment 1

[0059] (1) Take by weighing particle diameter and be 200g of ultra-high molecular weight polyethylene powder of 80 μm, described ultra-high molecular weight polyethylene is the M-I type product of Beijing Dongfang Petrochemical Co., Ltd. Auxiliary No. 2 Factory, and its molecular weight is 1,500,000;

[0060] (2) Weighing 50g of medical activated carbon powder with a particle diameter of 100 μm, the specific surface area of the medical activated carbon is 800m 2 / g;

[0061] (3) taking by weighing the sepiolite powder 100g that acidifies according to the acidification mode of the present invention with a particle diameter of 74 μm;

[0062] (4) taking by weighing the attapulgite powder 100g that acidifies according to the acidification mode of the present invention with a particle diameter of 85 μm;

[0063] (5) Take 50g of pore forming agent;

[0064] (6) Put the above five kinds of powders into a mechanical stirrer and stir for 10 minutes to mix evenly;

[0065] (7) Fil...

Embodiment 2

[0068] (1) Take by weighing 250 g of ultra-high molecular weight polyethylene powder with a particle size of 80 μm. The ultra-high molecular weight polyethylene is the M-III product of Beijing Dongfang Petrochemical Co., Ltd. Auxiliary No. 2 Factory, and its molecular weight is 3.5 million;

[0069] (2) Weighing 75g of medical activated carbon powder with a particle diameter of 100 μm, the specific surface area of the medical activated carbon is 1500m 2 / g;

[0070] (3) taking by weighing the sepiolite powder 150g that acidifies according to the acidification mode of the present invention with a particle diameter of 84 μm;

[0071] (4) taking by weighing the attapulgite powder 150g that acidifies according to the acidification mode of the present invention with a particle diameter of 75 μm;

[0072] (5) Take 75g of pore forming agent;

[0073] (6) Put the above five kinds of powders into a mechanical stirrer and stir for 10 minutes to mix evenly;

[0074] (7) Fill the mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com