Catalyst for synthesis of 3-acetoxy propionaldehyde

An acetoxy propionaldehyde, catalyst technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, organic compound/hydride/coordination complex catalyst, physical/chemical process catalyst, etc., can solve the problem of selectivity Low, high yield, high selectivity of 3-acetoxypropionaldehyde, to achieve the effect of improving activity and stability, improving yield and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation of catalyst: will contain 8.50gCo, contain 2.10gLi and contain the Co 2 (CO) 8 , LiCl and bismuth subsalicylate (C 7 h 5 BiO 4 ) fully mixed and dissolved in an aqueous acetic acid solution with a concentration of 10wt%, to obtain 400ml of impregnation solution, and the specific surface of 1.0L was 168m 2 / g, spherical SiO with a pore volume of 0.94 and a diameter of 5.6 mm 2 The carrier was immersed in the above impregnating solution, left to stand for 3 hours and dried at 100° C. to obtain the catalyst. The Co content of the catalyst measured by ICP is 8.50 g / L, the Li content is 2.10 g / L, and the Bi content is 2.80 g / L.

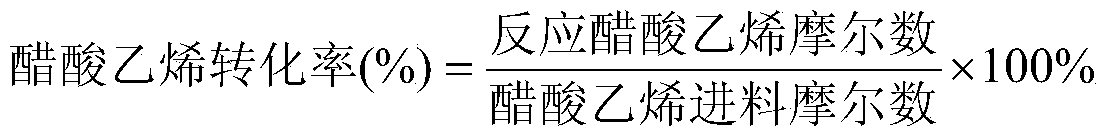

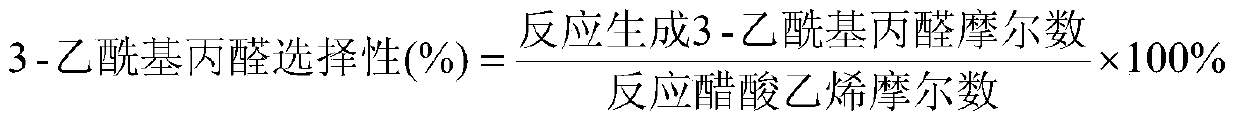

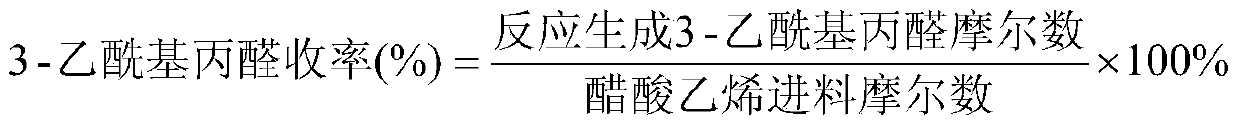

[0030] Synthesis of 3-acetoxypropionaldehyde: Add 2.50mol toluene, 0.15mol catalyst, 0.20mol triphenylphosphine and 1.65mol vinyl acetate into a 1L titanium reactor, first use argon to discharge the air in the reactor and then pressurize to 2.0MPa, then feed carbon monoxide and hydrogen until the pressure is 12.4MPa, increase t...

Embodiment 2

[0034] Preparation of the catalyst: the Co containing 8.50gCo, 2.10gLi and 2.80gAu 2 (CO) 8 , LiCl and ammonium tetrachloroaurate (NH 4 AuCl 4 2H 2 O) fully mixed and dissolved in the acetic acid aqueous solution with a concentration of 10wt%, to obtain 400ml of impregnation solution, and the specific surface of 1.0L was 168m 2 / g, spherical SiO with a pore volume of 0.94 and a diameter of 5.6 mm 2The carrier was immersed in the above impregnating solution, left to stand for 3 hours and dried at 100° C. to obtain the catalyst. The Co content of the catalyst was determined by ICP to be 8.50 g / L, the Li content was 2.10 g / L, and the Au content was 2.80 g / L.

[0035] Synthesis of 3-acetoxypropionaldehyde: Add 2.50mol toluene, 0.15mol catalyst, 0.20mol triphenylphosphine and 1.65mol vinyl acetate into a 1L titanium reactor, first use argon to discharge the air in the reactor and then pressurize to 2.0MPa, then feed carbon monoxide and hydrogen until the pressure is 12.4MPa, ...

Embodiment 3

[0046] Preparation of catalyst: Co(OAc) containing 7.00gCo, 0.50gNa and 1.00gBi 2 4H 2 O, Na 2 O and (BiO) 2 CO 3 0.5H 2 O is fully mixed and dissolved in an aqueous hydrochloric acid solution with a concentration of 8wt% to obtain 400ml of impregnation solution, and the specific surface of 1.0L is 200m 2 / g, spherical Al with a pore volume of 1.00 and a diameter of 5.6mm 2 o 3 The carrier was immersed in the above impregnating solution, left to stand for 3 hours and dried at 80° C. to obtain the catalyst. The Co content of the catalyst measured by ICP was 7.00 g / L, the Na content was 0.50 g / L, and the Bi content was 1.00 g / L.

[0047] Synthesis of 3-acetoxypropionaldehyde: Add 2.50mol toluene, 0.15mol catalyst, 0.20mol triphenylphosphine and 1.65mol vinyl acetate into a 1L titanium reactor, first use argon to discharge the air in the reactor and then pressurize to 2.0MPa, then feed carbon monoxide and hydrogen until the pressure is 12.4MPa, increase the stirring speed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com