A light-driven composite material with a double-layer film structure and its preparation method

A composite material and light-driven technology, which is applied in the direction of liquid crystal materials, chemical instruments and methods, coatings, etc., can solve the problems of poor film-forming property and complicated preparation process of light-driven materials, and achieve short preparation cycle, simple preparation operation, and applicable wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. The rubbing orientation of the polyimide substrate:

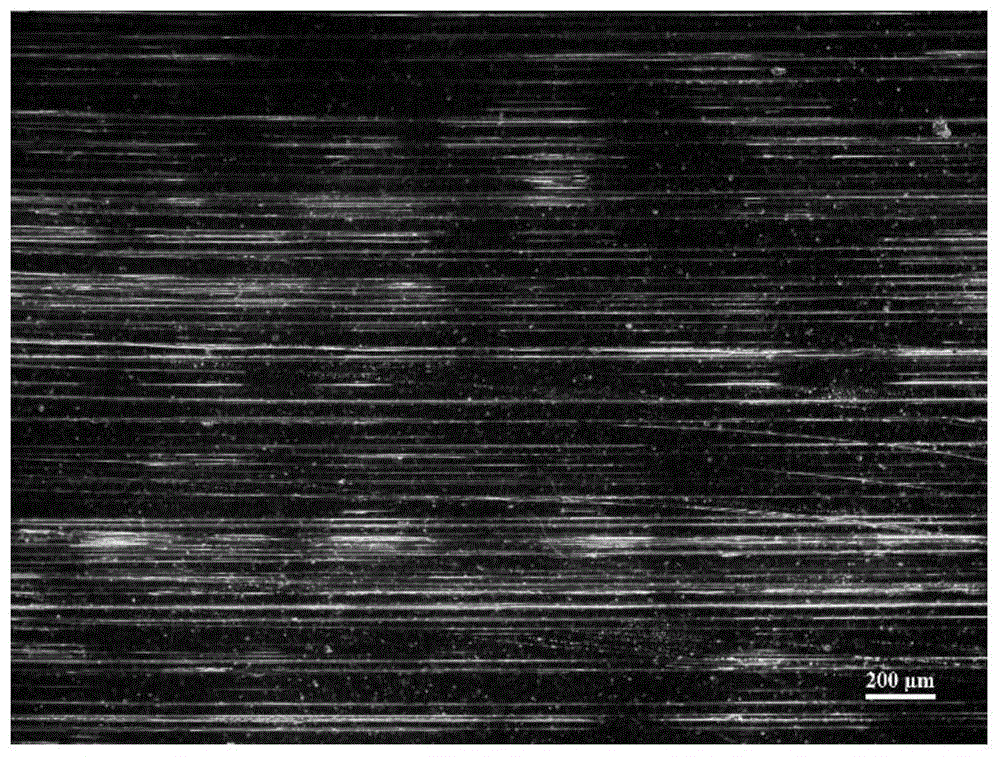

[0035] Select K-125 type polyimide film, and lightly sand it in one direction with sandpaper to form parallel micro-grooves on the polyimide surface, such as figure 2 shown.

[0036] 2. Preparation of liquid crystal composite film:

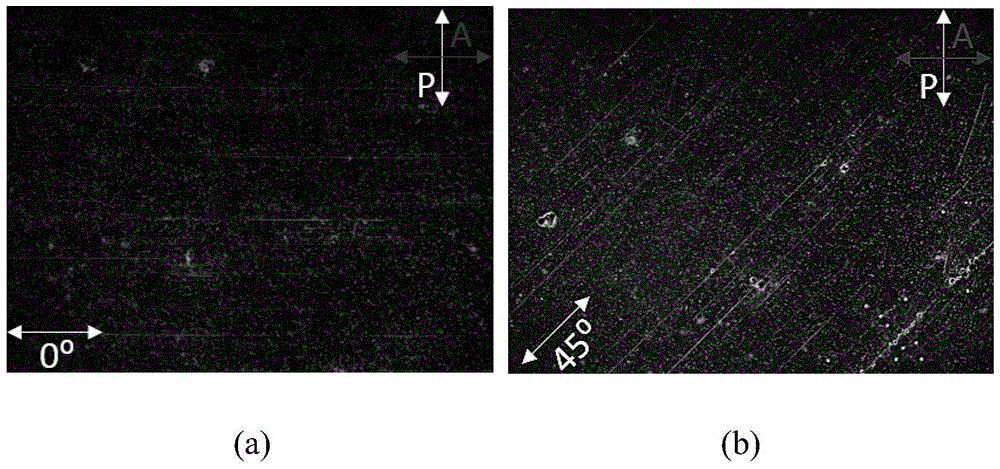

[0037] Take an appropriate amount of liquid crystal polymer 1, prepare a tetrahydrofuran solution with a concentration of 2 wt%, drop a layer evenly on the surface of the rubbed polyimide film, and dry it naturally at room temperature. The films were then annealed overnight at 150 degrees Celsius in a vacuum oven. After annealing, the photo-responsive groups are oriented. Under the polarizing microscope, the light and dark changes in the field of view can be observed with the change of angle, such as image 3 shown.

[0038]

[0039] 3. Optical drive phenomenon:

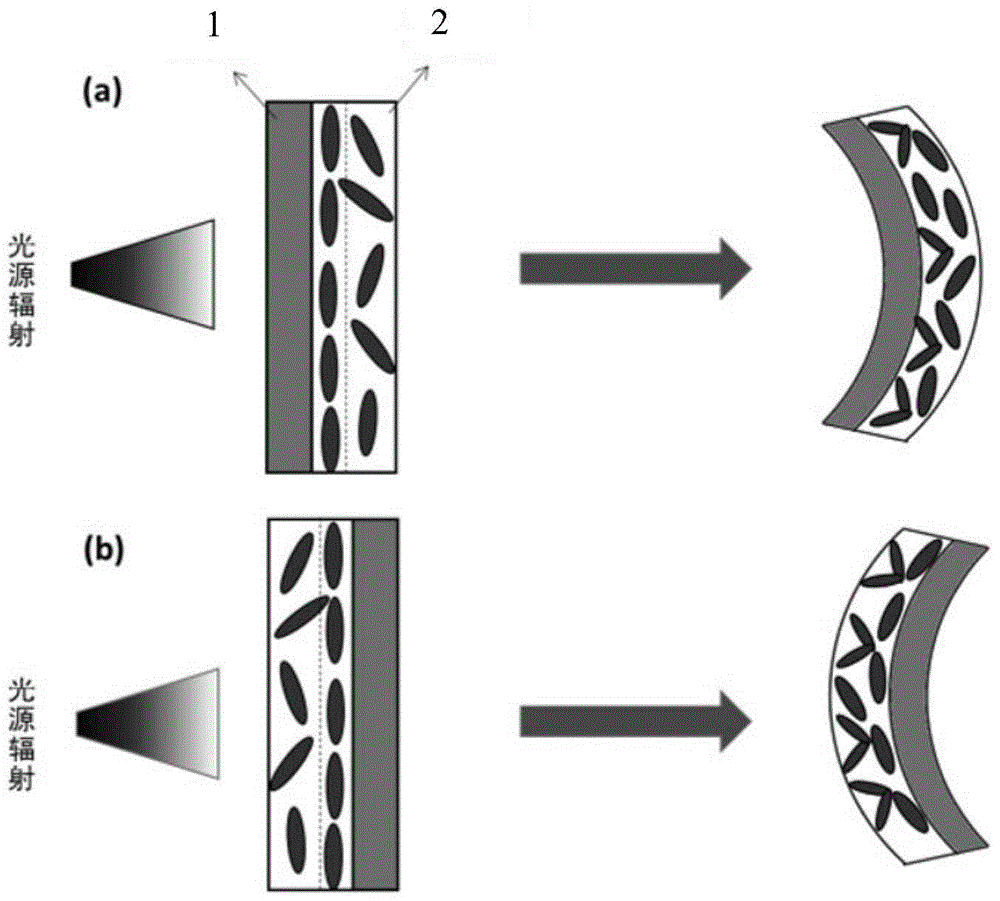

[0040] The above annealed film is taken and cut into splines of a certain size, with the liquid crystal polymer fac...

Embodiment 2

[0042] 1. The rubbing orientation of the polyester film substrate is the same as the rubbing of the polyimide film in Example 1.

[0043] 2. Preparation of composite film:

[0044] An appropriate amount of polymer 2 was taken to prepare a tetrahydrofuran solution with a concentration of 2 wt %, a layer was evenly dropped on the surface of the rubbed polyester film, and it was naturally dried at room temperature. The films were then annealed overnight at 80 degrees Celsius in a vacuum oven. After annealing, the photo-responsive groups were oriented, and under a polarizing microscope, the light and dark changes in the field of view could be observed with the change of the angle. By changing the intensity of the ultraviolet light, the degree of bending of the film will change, among which (L 0 and L are the original and bent lengths of the film, respectively).

[0045]

[0046] 3. The phenomenon of light driving is the same as that of Embodiment 1.

Embodiment 3

[0048] 1. The rubbing orientation of the polyvinyl alcohol substrate is the same as the rubbing of the polyimide film in Example 1.

[0049] 2. Preparation of complex 2+3:

[0050] Compounds 2 and 3 were dissolved in tetrahydrofuran solution respectively to form a solution. The two solutions were mixed according to the ratio of pyridine group and iodine atom at 1:1, stirred at room temperature, and after the solvent was evaporated to dryness, the obtained solid was vacuum-dried in a vacuum oven at room temperature to obtain compound 2+3.

[0051]

[0052] 3. Preparation of liquid crystal composite film:

[0053] An appropriate amount of compound 2+3 was taken to prepare a tetrahydrofuran solution with a concentration of 2wt%, a layer was evenly dropped on the surface of the rubbed polyvinyl alcohol film, and it was naturally dried at room temperature. The films were then annealed overnight at the liquid crystal temperature in a vacuum oven. After annealing, the liquid cr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com