Preparation method of large-size chalcogenide infrared glass based on salt bath quenching method

A technology of salt bath quenching and infrared glass, which is applied in the field of preparation of large-scale chalcogenide infrared glass based on the salt bath quenching method, which can solve the problems of poor heat transfer rate, large internal stress of the melt, and large temperature difference between inside and outside, and achieve The performance is stable and uniform, the process is simple and easy to operate, and the effect of good optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

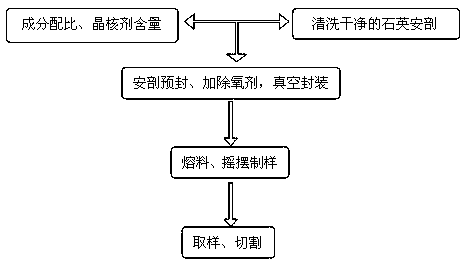

[0028] The present invention prepares the preparation method of large-scale chalcogenide infrared glass based on the salt bath quenching method: (see figure 1 :)

[0029] 1) Select a quartz tube with no cracks, no defects, and uniform thickness. First, fill the quartz tube with a molar ratio of 0.5% HF acid solution, soak for 2 hours, remove the impurities adhered to the quartz tube wall, and then rinse it with deionized water three times. After filling it with acetone and standing it for 24 hours, pour the acetone into the recovery bottle, rinse it with deionized water three times, and finally fill the quartz tube with deionized water and put it in an ultrasonic cleaner filled with water for 5 minutes, then pour it away Ionized water, put in a clean oven, dry at 130°C and put in a glass desiccator for later use;

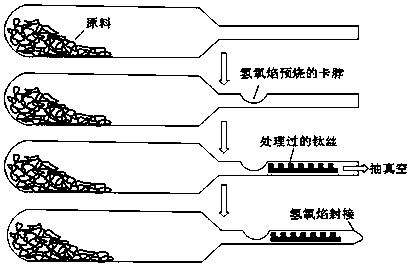

[0030] 2) Before loading, burn the front end of the quartz tube with a hydrogen-oxygen flame to burn a neck. The diameter of the neck is about half of the inner di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com