Preparation method of ivabradine hydrochloride crystal form variant DELTA-D

A technology of hydrochloride and crystal form, which is applied in the field of preparation of ivabradine hydrochloride crystal form variant DELTA-D, can solve the problems of product mixed crystals, difficult industrialization, and low product purity, and achieve increased purity, Ease of control and good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

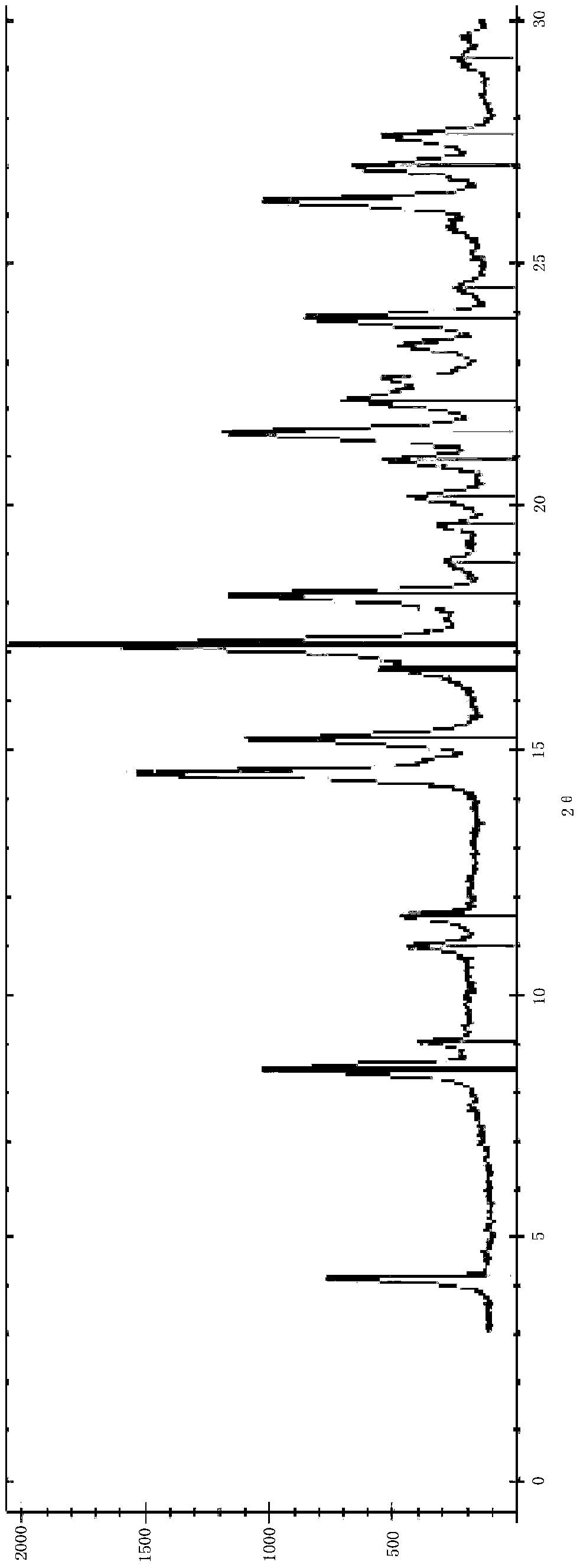

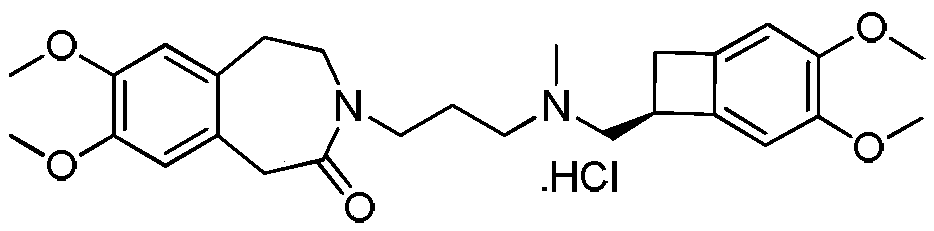

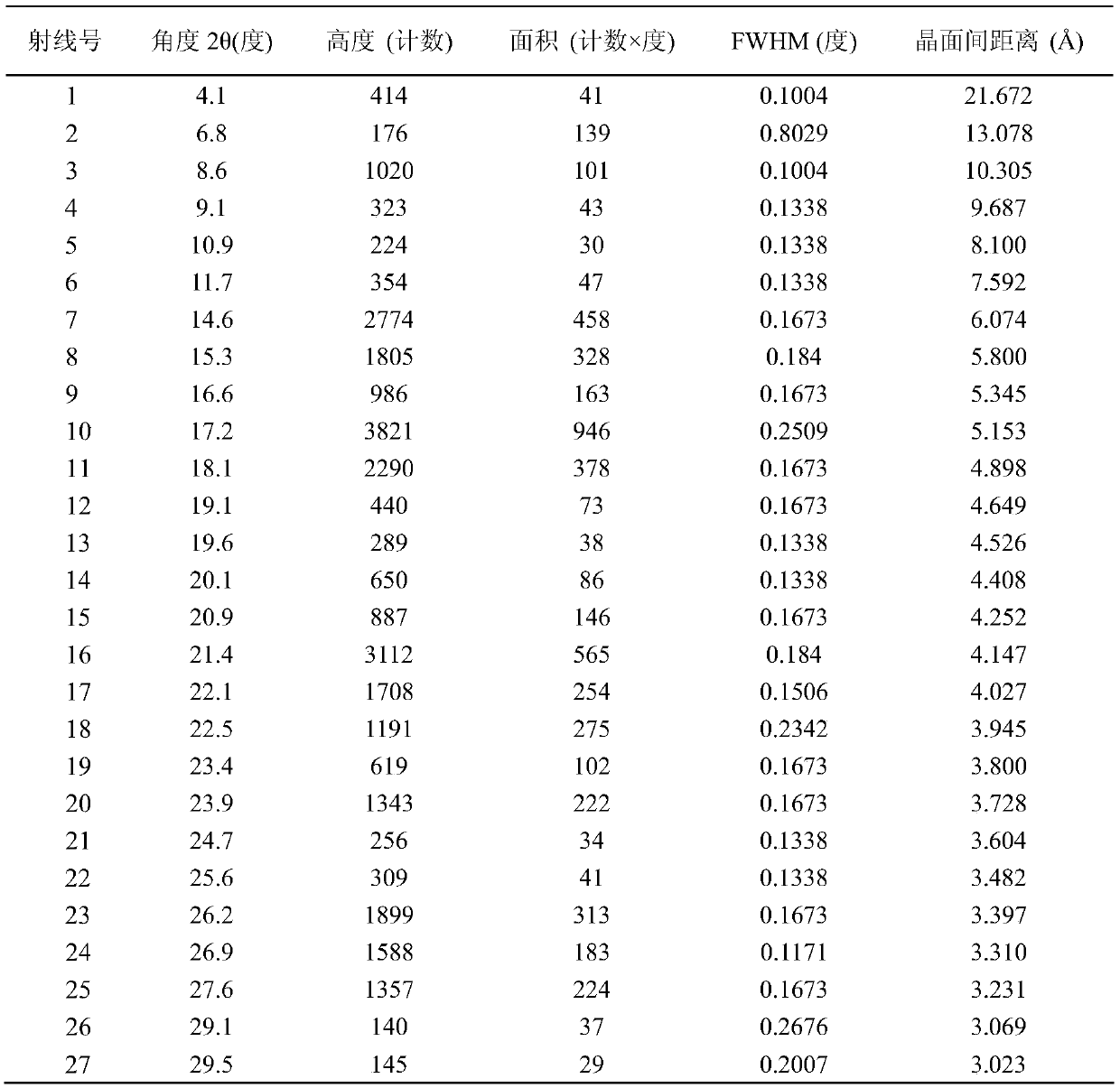

[0021] The present invention provides a method for preparing ivabradine hydrochloride crystal form variant DELTA-D, the XRD spectrum of the prepared DELTA-D crystal form is as follows figure 1 As shown, the 2θ peaks of the X-ray powder diffraction test are: 4.1, 8.6, 9.1, 10.9, 11.7, 14.6, 15.3, 16.6, 17.2, 18.1, 19.1, 19.6, 20.1, 20.9, 21.4, 22.1, 22.5, 23.4, 23.9 , 24.7, 25.6, 26.2, 26.9, 27.6, 29.1, 29.5. The specific data are shown in Table 1.

[0022] Table 1: X-ray powder diffraction spectrum characteristic peaks at 2θ of δ-d crystal form

[0023]

Embodiment 1

[0025] The preparation method of ivabradine hydrochloride crystal form modification DELTA-D in this embodiment comprises the following steps:

[0026] 1) Dissolving ivabradine hydrochloride crystal form α in acetone, wherein the water content of ivabradine hydrochloride crystal form α is 0.1%, the water content of acetone is 0.1%, and the amount of acetone is Ivabradine hydrochloride 5 times the dosage of bradine hydrochloride crystal form α;

[0027] 2) The temperature of the material obtained in step 1) was raised to 35°C, and stirred for 10 hours;

[0028] 3) Under a nitrogen atmosphere, filter the reaction system obtained in step 2), and dry the obtained solid under a vacuum environment, 0.8 MPa, 40°C, and dry for 24 hours.

[0029] After testing, the crystal form prepared in this example is pure crystal DELTA-D.

Embodiment 2

[0031] The preparation method of ivabradine hydrochloride crystal form modification DELTA-D in this embodiment comprises the following steps:

[0032] 1) Dissolving ivabradine hydrochloride crystal form δ in methyl ethyl ketone, wherein the water content of ivabradine hydrochloride crystal form δ is 0, and the water content of methyl ethyl ketone is 0.3 %, the amount of methyl ethyl ketone is 10 times that of ivabradine hydrochloride;

[0033] 2) The temperature of the material obtained in step 1) was raised to 30° C., and the reaction was stirred for 6 hours;

[0034] 3) Under a nitrogen atmosphere, filter the reaction system obtained in step 2), and dry the obtained solid under a vacuum environment, 1.0 MPa, 85° C., and dry for 12 hours.

[0035] After testing, the crystal form prepared in this example is pure crystal DELTA-D.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com