A kind of affinity biomembrane, preparation method and application thereof

A biofilm and affinity technology, applied in the field of affinity biofilm and preparation, can solve the problems of low adsorption efficiency, difficult to popularize and use in a wide range, high production cost, and achieve improved antifouling performance, improved hydrophilic performance and high production cost. Mechanical properties, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

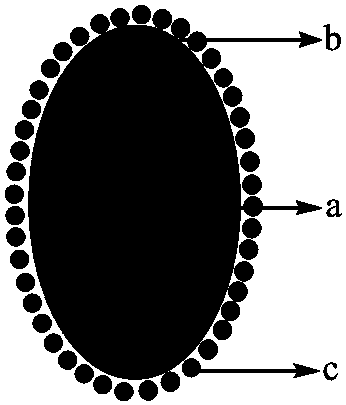

[0027] Preparation of Affinity Biofilm Using Polyethyleneimine or Polymyxin B as Ligand:

[0028] (1) Preparation of amphiphilic carbon materials (ACPs): take 10 g of brewer's yeast (provided by Henan Oak Brewery) and shake to disperse evenly, take the gray-white bacterial suspension in the upper layer and centrifuge, discard the waste liquid, and then add 10~ 15ml of acetone, place on a shaker and shake at 180 r / min for 10-20 min, centrifuge, discard the acetone supernatant, repeat the same method 3-5 times to obtain the cell wall of brewer's yeast, and use the substrate (the obtained cell wall) with Disperse 100ml of 2% (v / v) glutaraldehyde PBS buffer solution with pH=6.0, pour it into a high-temperature and high-pressure reaction kettle, put it into an oven, and hydrothermally carbonize it at 150-200°C for 8-10 hours. After the reaction, cool To room temperature, pour off the upper layer solution, add 100~150ml of distilled water to the lower layer of sediment for ultrasoni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com