Silicone rubber material for flexible joint and preparation method of silicone rubber material

A flexible joint and silicone rubber technology, applied in the field of silicone rubber materials for flexible joints and their preparation, can solve the problem that the mechanical tensile strength is only 1MPa ~ 2MPa, lower than 25 degrees, and some even have only ten degrees, which cannot be used. life and other issues, to achieve the effect of improving mechanical strength, low price, and improving high and low temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

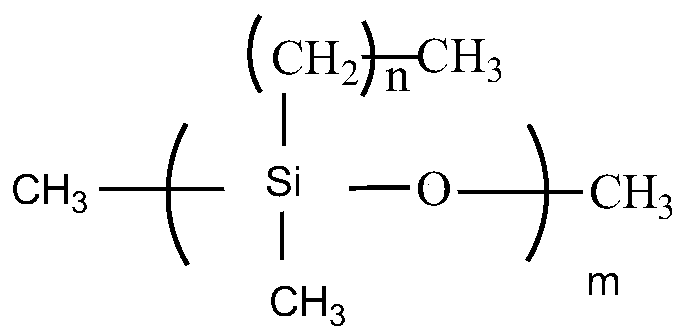

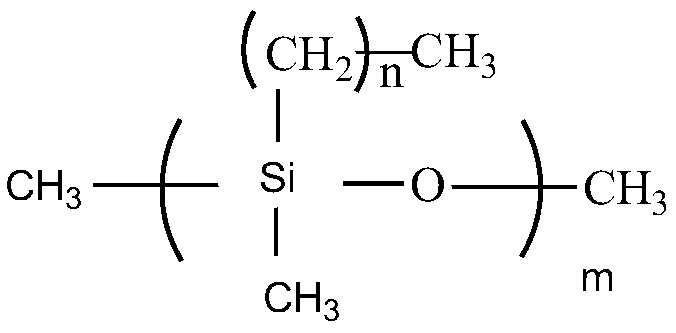

Method used

Image

Examples

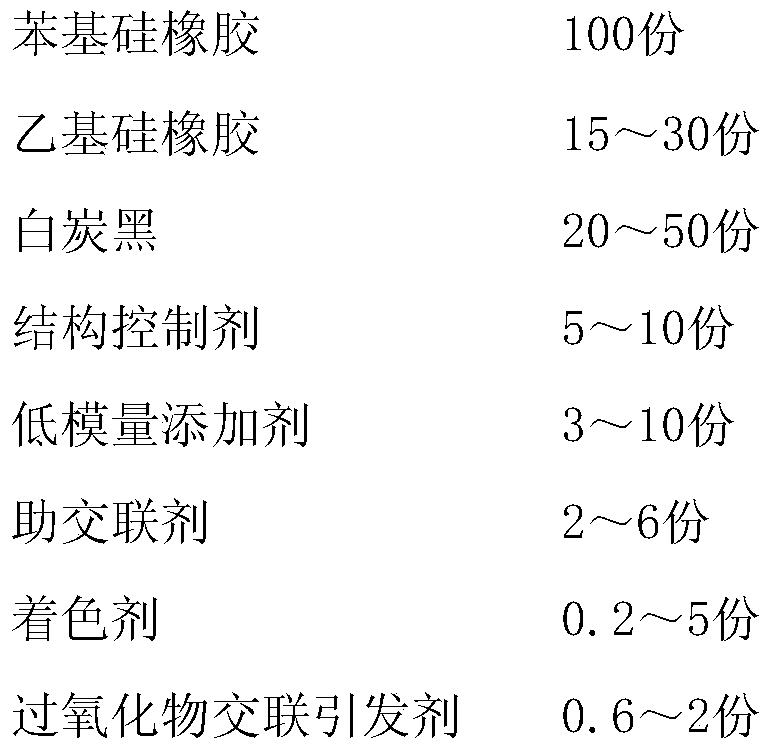

Embodiment 1

[0050] Formula composition: 100 parts of phenyl silicone rubber, 30 parts of ethyl silicone rubber, 50 parts of fumed silica A-38050, 10 parts of hexamethylcyclotrisilazane, 10 parts of long-chain alkyl silicone oil, polyvinyl silicone oil 2 parts, 0.5 parts of chrome green, 2,5-dimethyl-2,5-di-tert-butylperoxyhexane, 0.6. According to the proportion and the above-mentioned preparation process, the test pieces satisfying various performance tests in the table were prepared. Then measure the physical and mechanical properties of the silicone rubber vulcanizate samples according to GB / T528-2009, GB / T531.1-2008, the results are shown in Table 1.

Embodiment 2

[0052]Formula composition: 100 parts of phenyl silicone rubber, 15 parts of ethyl silicone rubber, 20 parts of fumed silica A-38020, 6 parts of hexamethylcyclotrisilazane, 3 parts of long-chain alkyl silicone oil, polyvinyl silicone oil 6 parts, 1 part of chrome green, 2 parts of 2,5-dimethyl-2,5-di-tert-butylperoxyhexane. According to the proportion and the above-mentioned preparation process, the test pieces satisfying various performance tests in the table were prepared. Then measure the physical and mechanical properties of the silicone rubber vulcanizate samples according to GB / T528-2009, GB / T531.1-2008, the results are shown in Table 1.

Embodiment 3

[0054] Formula composition: 100 parts of phenyl silicone rubber, 20 parts of ethyl silicone rubber, 40 parts of fumed silica A-20040, 10 parts of hydroxyl silicone oil, 8 parts of long chain alkyl silicone oil, 3 parts of polyvinyl silicone oil, 5 parts of iron red Parts, dicumyl peroxide, 1 part. According to the proportion and the above-mentioned preparation process, the test pieces satisfying various performance tests in the table were prepared. Then measure the physical and mechanical properties of the silicone rubber vulcanizate samples according to GB / T528-2009, GB / T531.1-2008, the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com