A method for the separation and purification of gallate decarboxylase

An acid decarboxylase, separation and purification technology, applied in the biological field, can solve problems such as instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The crude extraction of embodiment 1 gallate decarboxylase (GAD)

[0041] Gallate decarboxylase (GAD) is an intracellular enzyme, that is, it is produced in the cell by biological cells. In order to obtain the intracellular enzyme, the simplest and most effective way to obtain the crude enzyme solution is to crush the cells and then centrifuge. From the research on the degradation process, in order to ensure the reproducibility of the experiment and the sustainability of the follow-up work, the bacterial cells under the optimal process above were treated with phosphoric acid containing 1mM dithiothreitol and 50mM sodium thiosulfate. Wash twice with salt buffer solution (pH 6.0), ultrasonically pulverize for 45 min at 4°C (5 s, interval 5 s), centrifuge for 20 min at 4°C (10000r min -1 ), that is, extract 100 mL of crude enzyme liquid from 12 bottles of fermentation liquid, and store it at 4°C for future use.

Embodiment 2

[0042] The salting-out of embodiment 2 gallate decarboxylase (GAD)

[0043] Effect of salt concentration on salting-out: take eight 18×180mm test tubes, add ammonium sulfate 1.0, 2.0, 3.0, 4.0, 5.0, 6.0, 7.0, 8.0g respectively, add 10mL distilled water to dissolve, stir evenly with a glass rod, make it fully Dissolve, then add 2mL of GAD crude enzyme solution respectively, seal and leave it in the refrigerator overnight to estimate the amount of flocs. It can be seen from Table 1 that when the concentration of ammonium sulfate is between 20% and 60%, the amount of flocs shows a continuous increase trend, and when the concentration of ammonium sulfate is between 60% and 80%, the amount of precipitation basically tends to be stable. For 60% ammonium sulfate, the concentrations of 60% and 70% ammonium sulfate can be selected for the two precipitations, so that the protein can be precipitated as much as possible.

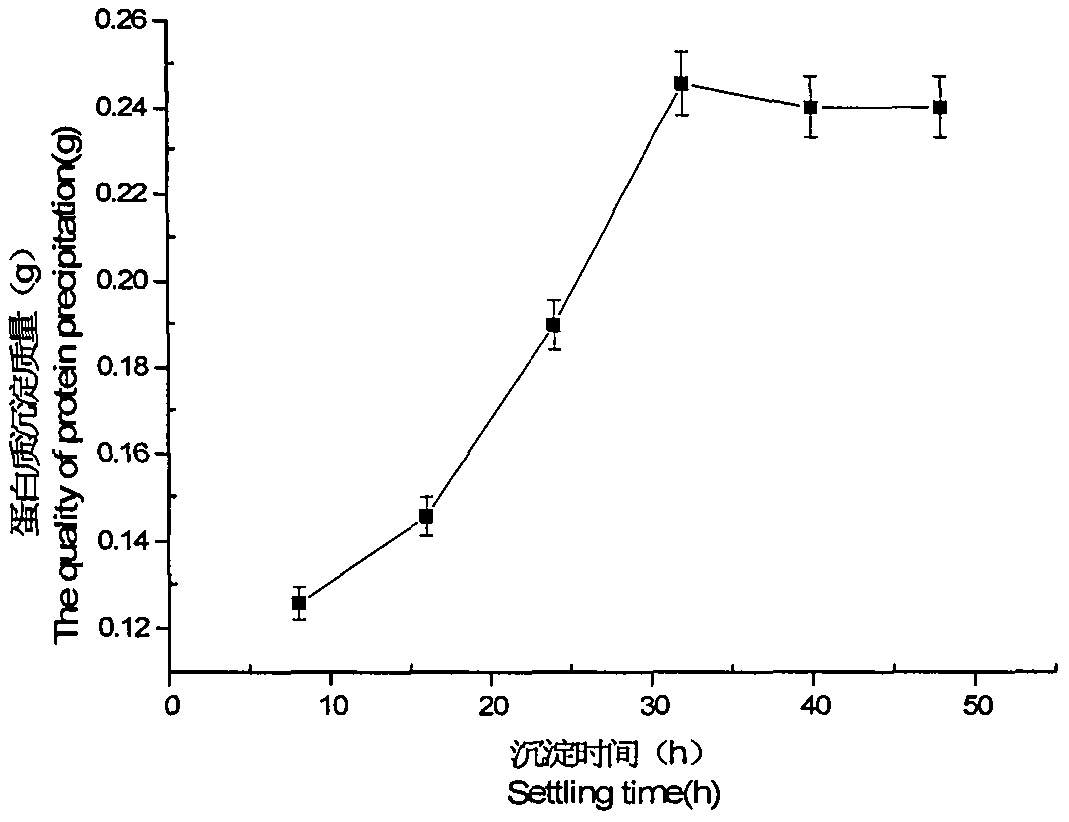

[0044] Effect of precipitation time on salting-out: take five 18×...

Embodiment 3

[0046] Example 3 Dialysis of gallate decarboxylase (GAD): From the results in the second step, the approximate range of the protein in the crude enzyme solution is 50-70kD, so the molecular weight of the permeable protein is selected to be 3500-5000kD and 8000-14000kD respectively dialysis membrane for separation. Depend on Figure 4 It can be seen that the molecular weight of the protein extracted by ammonium sulfate is mainly distributed in the range of 50-100kD, and the protein content of 70-90kD is the highest. Therefore, the use of 80kD dialysis membrane filtration can retain large molecules and remove impurities of small molecules. Utilize the dialysis membrane filtration of 80kD size, investigate the influence of time with 500mL feed liquid as benchmark. Depend on Figure 5 It can be seen that the protein content in the permeate decreased with the increase of time. The decrease was not obvious in the first 6 hours, and it decreased sharply in the 8-16 hours, and then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com