A kind of comprehensive utilization method of electrolysis of naphthoquinone raffinate

A technology for naphthoquinone residue and naphthoquinone is applied in the field of comprehensive treatment and utilization of naphthoquinone residue, which can solve the problems of high energy consumption, increased production cost, low electrolysis current efficiency, etc., and achieves high chromium recovery rate, low energy consumption, low The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

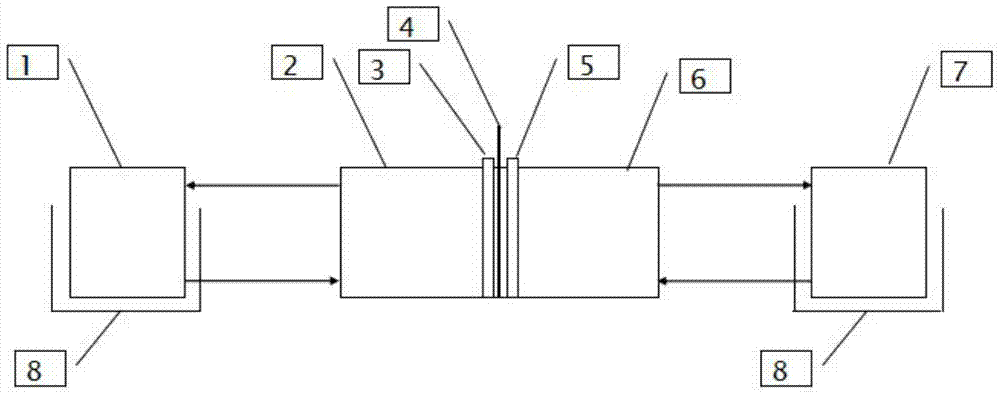

Image

Examples

Embodiment 1

[0032] Take 4L of naphthoquinone raffinate and filter it through a filter cloth with a pore size of 10um, and return the filter residue to the naphthoquinone production line for ingredients; take 2L of the filtrate and add concentrated sulfuric acid to make anolyte, Cr 6+ Content is 0.25mol / L, sulfuric acid mass ratio (as H 2 SO 4 Calculate) 10%, add the anode circulation tank of electrolytic cell; Get 2L filtrates and add boric acid, acetamide, sodium acetate to be mixed with catholyte in addition, chromium content (as Na 2 Cr 2 o 7 total) 0.30mol / L, boric acid 50g / L, acetamide 10g / L, sodium acetate 10g / L, add to the cathode circulation tank of the electrolytic cell; At 65°C, start the circulating pump, the cathode and anode liquids enter the corresponding cathode and anode chambers for circulation respectively, and pass 500A / m to the cathode and anode plates of the electrolytic cell 2 direct current, cell voltage 3-6V, Cr in the anolyte after electrolysis for 20 hours 3...

Embodiment 2

[0036]Take 4L of naphthoquinone raffinate and filter it through a filter cloth with a pore size of 10um, and return the filter residue to the naphthoquinone production line for ingredients; take 2L of the filtrate and add concentrated sulfuric acid to make anolyte, Cr 6+ Content is 0.3mol / L, sulfuric acid mass ratio (as H 2 SO 4 Calculate) 30%, add the anode circulation tank of electrolytic cell; Get 2L filtrates and add boric acid, acetamide, sodium acetate to be mixed with catholyte in addition, chromium content (as Na 2 Cr 2 o 7 Add 0.30mol / L, 100g / L boric acid, 30g / L acetamide, and 30g / L sodium acetate to the cathode circulation tank of the electrolytic cell; start the constant temperature system of the cathode and anode circulation tank to keep the temperature of the cathode and anode liquid at 65°C, Start the circulation pump, the cathode and anode liquids enter the corresponding cathode and anode chambers for circulation respectively, and pass 800A / m to the cathode a...

Embodiment 3

[0040] Take 8L of naphthoquinone raffinate and filter it through a filter cloth with a pore size of 20um, and return the filter residue to the naphthoquinone production line for ingredients; take 4L of the filtrate and add concentrated sulfuric acid to prepare anolyte, Cr 6+ Content is 0.28mol / L, sulfuric acid mass ratio (as H 2 SO 4 Calculate) 20%, add the anode circulation tank of electrolytic cell; Get 4L filtrate and add boric acid, acetamide, sodium acetate to be mixed with catholyte in addition, chromium content (as Na 2 Cr 2 o 7 0.30mol / L, boric acid 80g / L, acetamide 50g / L, sodium acetate 60g / L, add to the cathode circulation tank of the electrolytic cell; start the cathode and anode circulation tank constant temperature system to make the temperature of the cathode and anode liquid at 60 ° C, Start the circulation pump, the cathode and anode liquids enter the corresponding cathode and anode chambers for circulation respectively, and pass 500A / m to the cathode and an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com