Method for obtaining engineering machinery tyre vertical characteristic parameters based on pulse test

A pulse test and construction machinery technology, applied in special data processing applications, electrical digital data processing, instruments, etc., can solve problems such as errors, restrict product development reliability, and difficulty in confirming calculation accuracy by vehicle manufacturers, and achieve parameter physics The effect of clarifying the meaning and reducing the cost of the test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

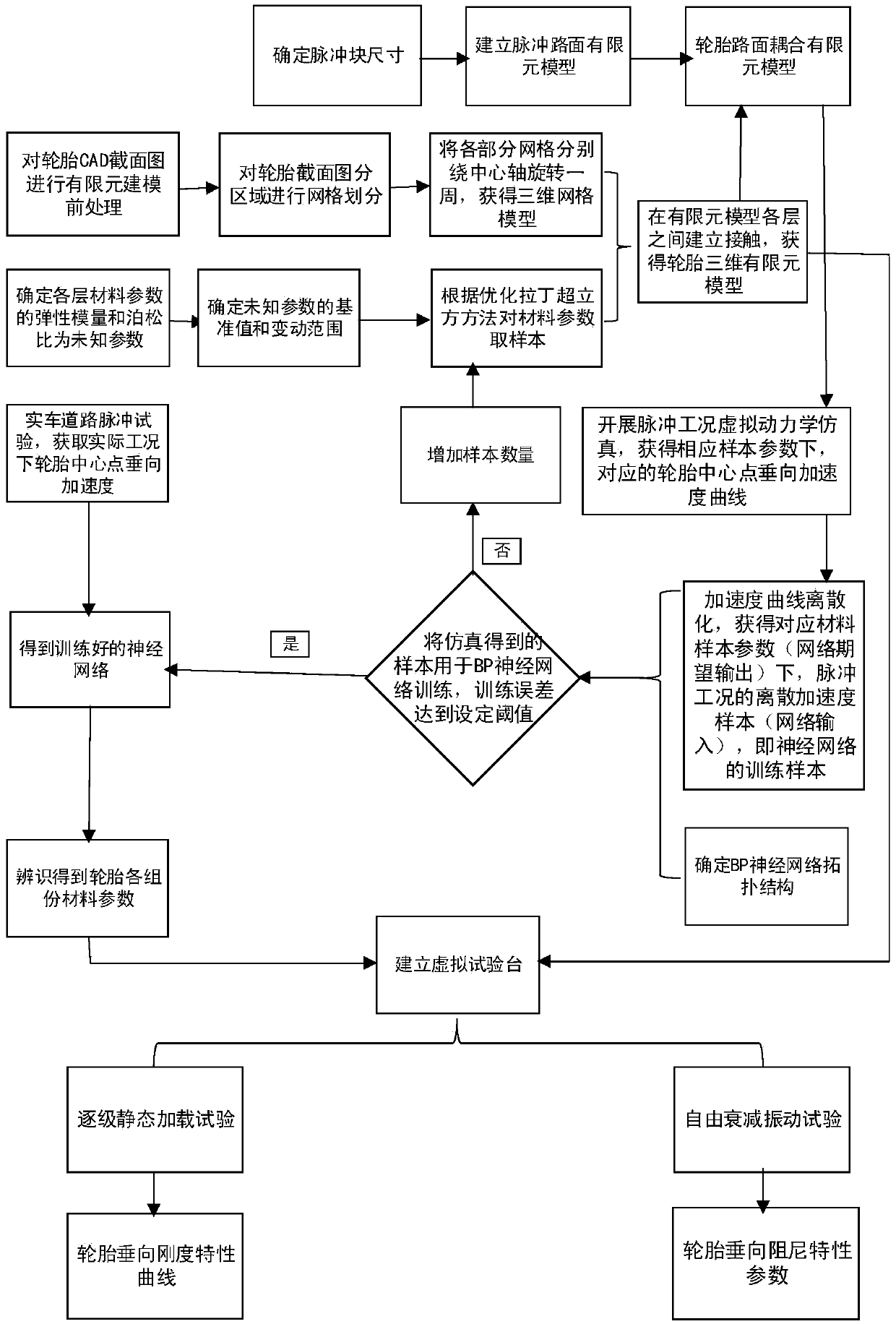

[0053] See attached Figure 1-11 ;

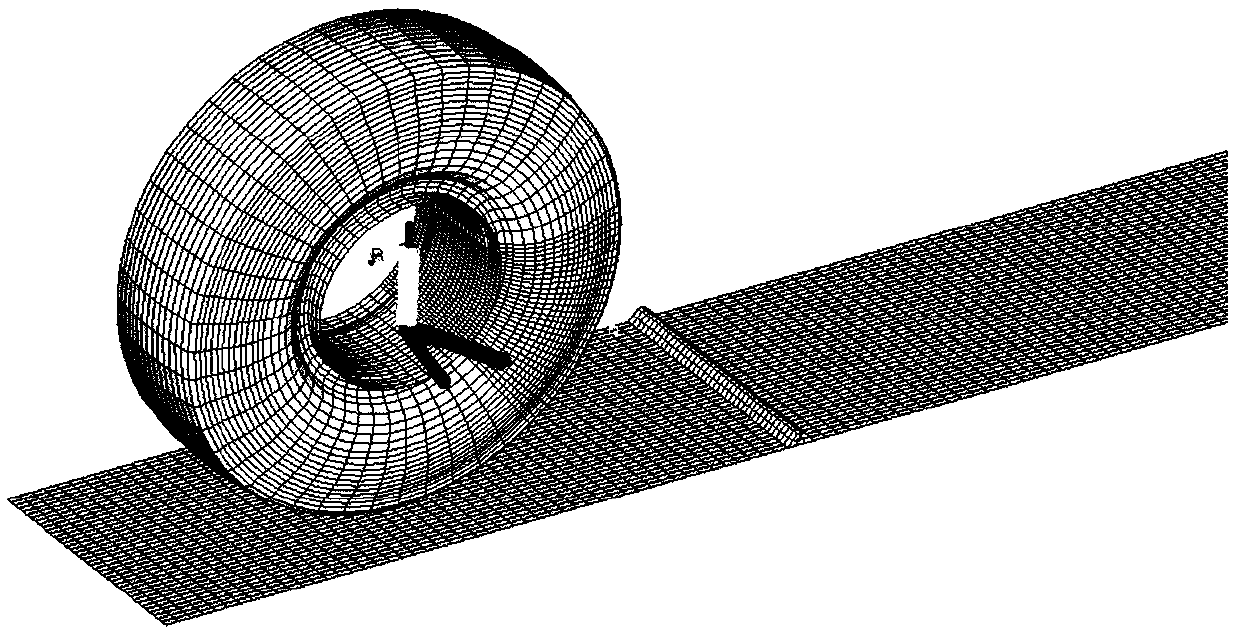

[0054] The method of obtaining vertical characteristic parameters of off-road tires based on pulse test, the flow chart is as follows figure 1 , including the following steps:

[0055] Step 1. Establish tire-road coupling 3D finite element model

[0056] The diameter of the tire is 3866mm.

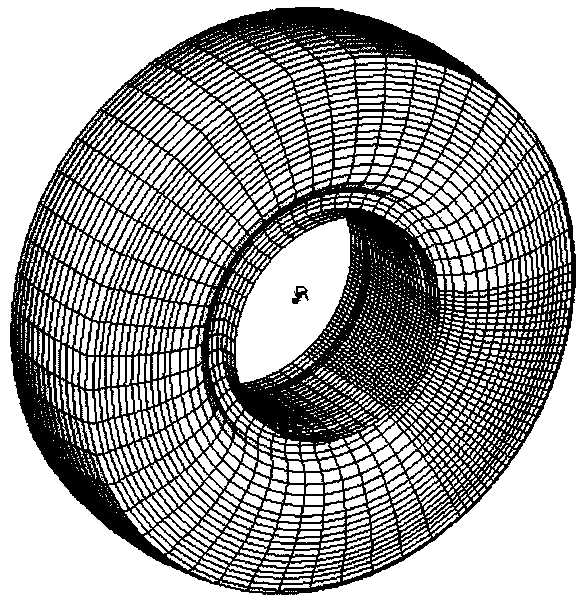

[0057] First, draw the tire CAD cross-sectional profile according to the tire size data, see the attached figure 2 According to the different properties of the tire materials, the tire CAD cross-sectional profile is divided into four parts: steel ring, ply layer, belt layer and rubber layer. In the four parts, the side length is 5-10mm, respectively. A quadrilateral mesh is divided in each part, see appendix image 3 ; Rotate the tire CAD cross-sectional contour diagram 360° around the tire central axis to obtain a three-dimensional finite element model of the tire partitioned by material properties, see the attached Figure 4 ;Contact is establi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com