Preparation method of Cu nanoparticles-embedded ordered mesoporous carbon catalyst

A technology of catalyst and mesoporous carbon, which is applied in the field of ordered mesoporous carbon catalyst and its preparation, can solve the problems of reduced catalytic activity, high reactivity, and good dispersion of the catalyst, and achieve uniform and orderly pores, high reactivity, Good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

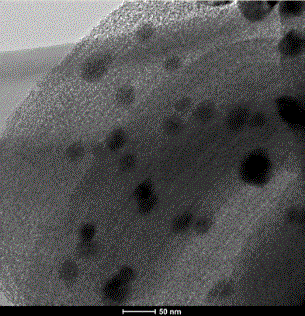

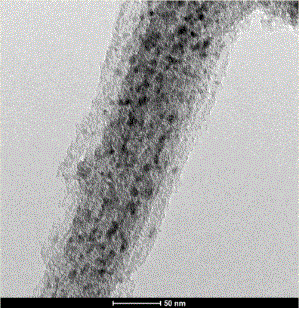

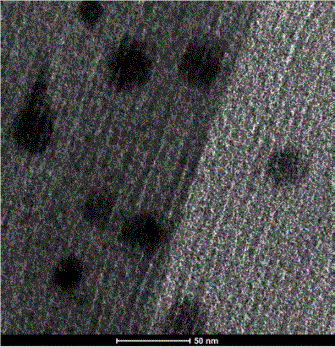

Image

Examples

Embodiment 1

[0032] Add 1g of mesoporous silicon material SBA-15 to a mixed solution containing 1.25g of sucrose, 0.14g of concentrated sulfuric acid and 5ml of deionized water, and ultrasonically disperse the mixture in an ultrasonic oscillator for 20min; then place it in an electric blast drying oven Dry at 80°C for 6 hours. After drying, adjust the temperature to 160°C to pre-carbonize sucrose in the pores of SBA-15 for 6 hours. Weigh 0.8g sucrose, 0.09g sulfuric acid, 0.1g copper nitrate trihydrate and 5ml deionized water to make a solution, add this solution to the composite sample of SBA-15 and sucrose semipolymer prepared in the previous step, and ultrasonically disperse for 20min , followed by drying at 80°C for 6h and pre-carbonization at 160°C for 6h. The obtained sample was placed in a nitrogen-protected tube furnace, and the temperature was raised to 400°C at a rate of 2°C / min, then to 900°C at a rate of 1°C / min, and kept at a constant temperature for 4h. Finally, the complex ...

Embodiment 2

[0035] Add 1 g of mesoporous silicon material SBA-15 to a mixed solution containing 1.25 g of sucrose, 0.14 g of concentrated sulfuric acid, 0.1 g of copper nitrate trihydrate and 5 ml of deionized water, and ultrasonically disperse the mixture in an ultrasonic oscillator for 20 min; The sample was dried in an electric blast drying oven at 100°C for 6 hours. After drying, the temperature was adjusted to 160°C to prepolymerize sucrose in the pores of SBA-15 for 6 hours. Weigh 0.8g sucrose, 0.09g sulfuric acid and 5ml deionized water to make a solution, add this solution to the composite sample of SBA-15 and sucrose semipolymer prepared in the previous step, ultrasonically disperse for 20min, and then dry at 100°C 6h, pre-carbonization at 160°C for 6h. The obtained sample was placed in a nitrogen-protected tube furnace, and the temperature was raised to 400°C at a rate of 2°C / min, then to 900°C at a rate of 1°C / min, and kept at a constant temperature for 4h. Finally, the composi...

Embodiment 3

[0038] Add 1g of mesoporous silicon material SBA-15 to a mixed solution containing 1.25g of sucrose, 0.14g of concentrated sulfuric acid, 0.05g of copper acetate monohydrate and 5ml of deionized water, and ultrasonically disperse the mixture in an ultrasonic oscillator for 20min; The samples were dried in an electric blast drying oven at 100°C for 6 hours. After drying, the temperature was adjusted to 160°C to pre-carbonize the sucrose in the pores of SBA-15 for 6 hours. Weigh 0.8g sucrose, 0.09g sulfuric acid, 0.03g copper acetate monohydrate and 5ml deionized water to make a solution, add this solution to the composite sample of SBA-15 and sucrose semipolymer prepared in the previous step, and ultrasonically disperse for 20min , followed by drying at 100°C for 6h and pre-carbonization at 160°C for 6h. The obtained sample was placed in a nitrogen-protected tube furnace, and the temperature was raised to 400°C at a rate of 2°C / min, then to 850°C at a rate of 1°C / min, and kept ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com