Plasma 3D (three-dimensional) fast forming equipment and method for rollers

A molding equipment, plasma technology, applied in the field of ion 3D rapid prototyping equipment and molding, can solve the problems of cracking, complex structure, scrapping and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

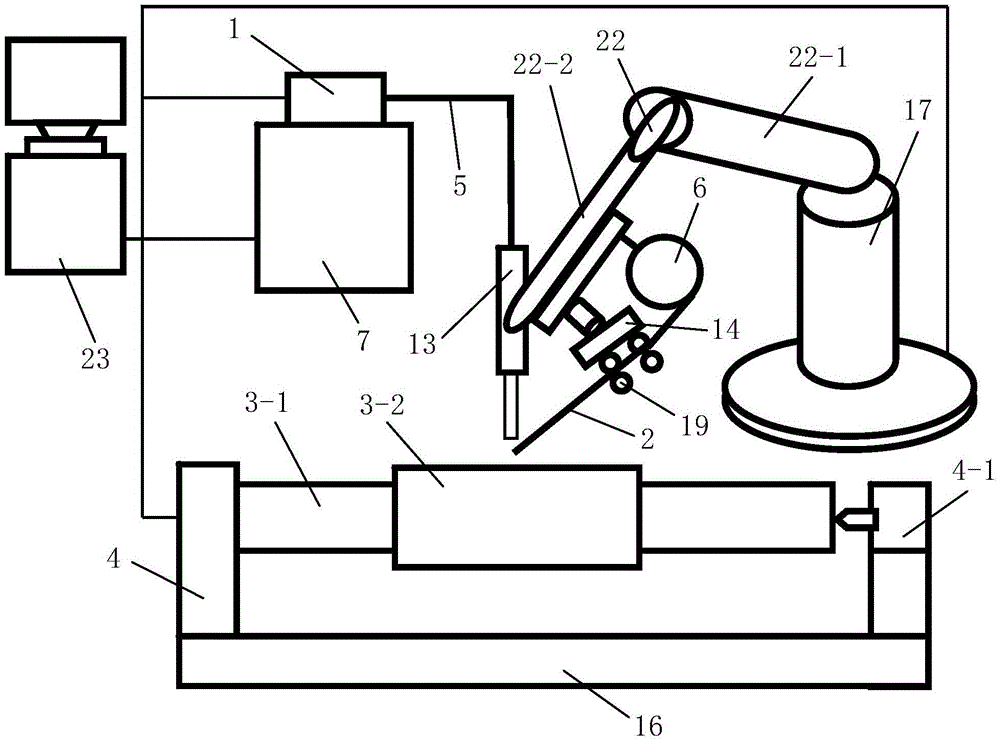

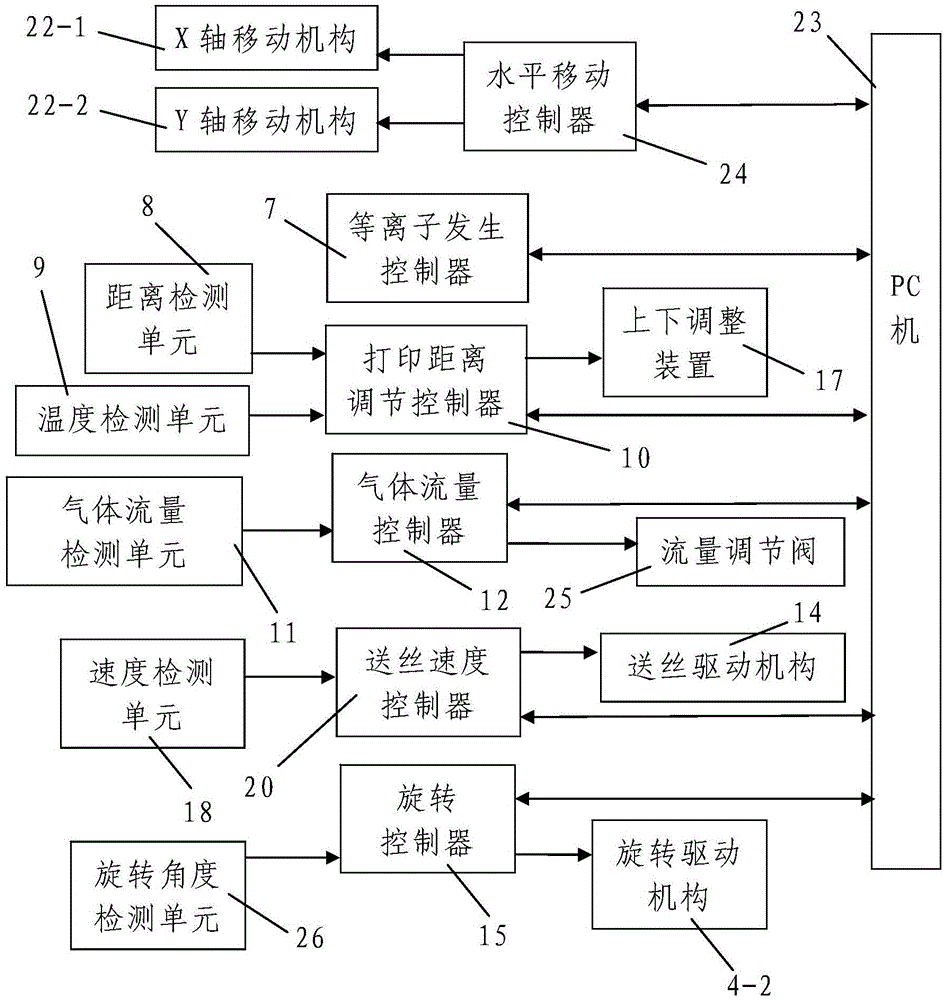

[0088] Such as figure 1 A roll plasma 3D rapid prototyping equipment shown is composed of a monitoring system, a plasma beam processing system and a horizontal printing platform for placing a roll to be formed. The roll to be formed includes a roll core 3-1 and is arranged on the roll core 3 - The outer layer 3-2 of the roller body outside the middle part, the outer layer 3-2 of the roller body is coaxially arranged with the roller core 3-1; the horizontal printing table includes a horizontal support mechanism 16 and is fixedly installed on the horizontal support mechanism 16 And the horizontal rotation mechanism 4 that drives the roller core 3-1 to rotate around its central axis, the horizontal rotation mechanism 4 is located above the horizontal support mechanism 16, the roller core 3-1 is arranged horizontally and installed on the horizontal rotation mechanism 4 superior.

[0089]The plasma beam processing system consists of a plasma generator equipped with a shower head a...

Embodiment 2

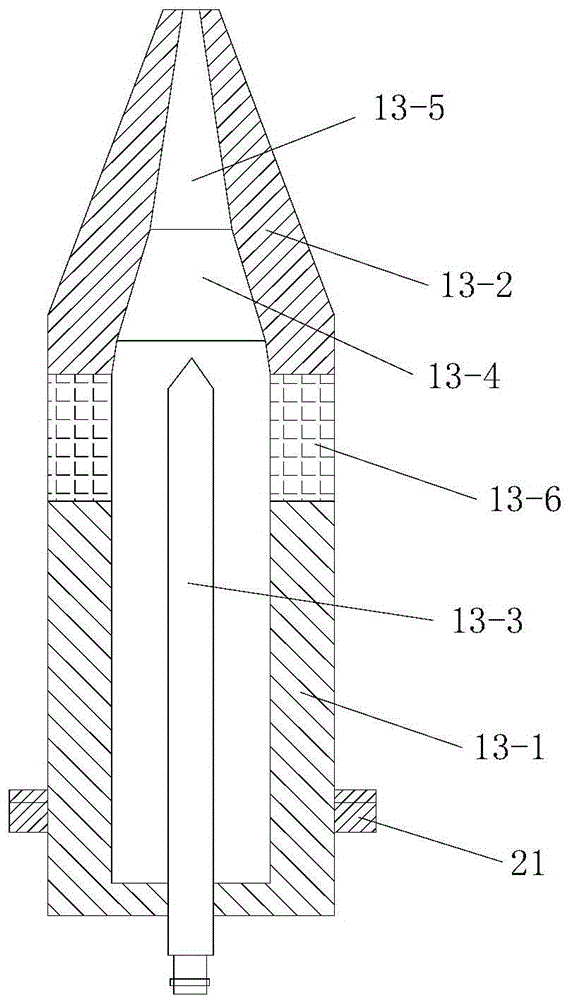

[0203] In this example, if Figure 7 As shown, the difference between the roll plasma 3D rapid prototyping equipment used and the embodiment 1 is that the angle between the nozzle 13-5 and the central axis of the gun body 13-1 is 30°-45°.

[0204] In this way, after changing the direction of the plasma beam through the nozzle 13-5, the thermal load impact of the plasma jet on the anode nozzle 13-2 can be effectively reduced, and the anode ablation condition is improved.

[0205] In this embodiment, the structure, connection relationship and working principle of the remaining parts of the roll plasma 3D rapid prototyping equipment are the same as those in Embodiment 1.

[0206] In this embodiment, the roll plasma 3D rapid prototyping method adopted is the same as that in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com