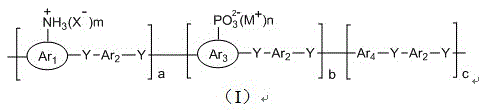

Random polymers with framework containing ammonium and phosphonic acid groups, and preparation method thereof

A phosphonic acid-based, polymer technology, used in chemical instruments and methods, reverse osmosis, membrane technology, etc., can solve problems such as less research and difficult polymers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

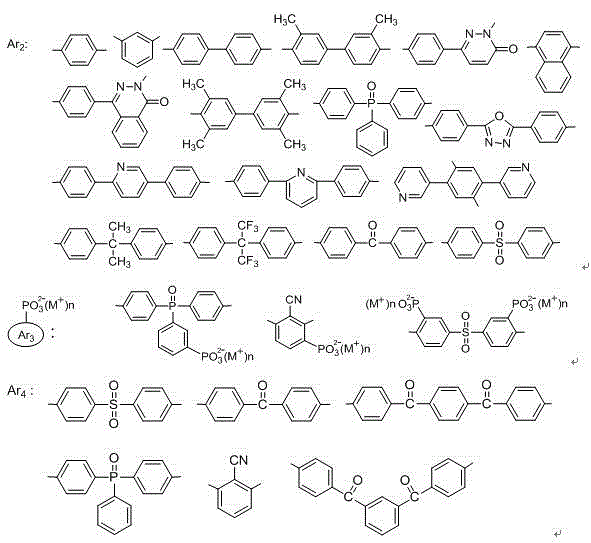

Method used

Image

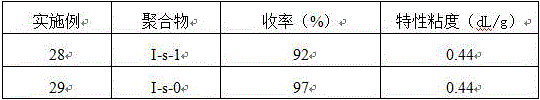

Examples

Embodiment 1

[0028] Example 1: Preparation of Polymer (I-a-1)

[0029]

[0030]Under nitrogen atmosphere, 0.33g (1.0mmol) bis (4-fluorophenyl) (3-aminophenyl) phosphine oxide (ABFPPO), 0.44g (1.0mmol) bis (4-fluorophenyl) (3'- Sodium phosphonate phenyl) phosphine oxide (PBFPPO), 5.66g (18.0mmol) bis (4-fluorophenyl) phenyl phosphine oxide (BFPPO), 3.72g (20.0mmol) 4,4'- biphenyl diphenol ( BP) and 3.18g (23.0mmol) of anhydrous potassium carbonate were added to a 100.0mL straight-necked three-necked flask equipped with a water separator, a serpentine condenser, a stirrer and an air guide tube, and then 40.0mL of N,N-di methylacetamide (DMAC) and 20.0 mL of toluene. Raise the temperature to 160°C, reflux at this temperature with water for 12 hours, then drain the toluene through a water separator, rise to 185°C and continue the reaction at this temperature for 3h to obtain a brown viscous solution. Pour it into deionized water to obtain a light brown strip-shaped polymer, filter it, the...

Embodiment 2

[0031] Example 2: Preparation of Polymer (I-a-0)

[0032]

[0033] Take 2 grams of (I-a-1) to make 20% N-methylpyrrolidone solution (NMP) (w / v), heat to reflux, and keep it for 1 hour, lower the temperature to 120°C, then pour it into deionized In water, a fibrous polymer was obtained, then soaked at 60-80°C for 10 hours, repeated 5 times, filtered, dried, and vacuum-dried to obtain 1.9 g of polymer (I-a-0) with a yield of 99%. Intrinsic viscosity: 0.54dL / g.

Embodiment 3-16

[0035] Referring to the test methods of Examples 1 and 2, feeding was carried out according to the molar ratio of ABFPPO: PBFPPO: BFPPO: BP=x:y:z:1, and a series of polymers (I-letter-1) and (I-letter-1) were prepared. -0) (letter=a-h):

[0036]

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com