Straw-wound composite pipe and preparation method thereof

A composite pipe and straw technology, applied in the field of composite pipes, can solve the problems of narrow application range, complex process, and lack of versatility of square pipes, and achieve the effects of improved production and processing efficiency, extensive resources, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The method for preparing the above-mentioned straw-wound composite pipe in a specific embodiment of the present invention includes the following steps:

[0029] Straw pretreatment: remove the remaining part of the straw except the stem, dry the stem and cut it into the same length;

[0030] Preparation of the inner lining layer: use fabric and adhesive to make an anti-corrosion and anti-seepage inner lining layer on the straight pipe mold;

[0031] Preparation of the straw structure layer: Wrap the mesh cloth on the inner lining layer, set a hopper above the mesh cloth to output the straw stems in the same direction, so that the straw stems are laid on the mesh in parallel and closely as the mesh cloth is conveyed to the mold. On the grid cloth, the laying direction is the same as the conveying direction of the mesh cloth, or at a certain angle to the conveying direction of the mesh cloth, and then the laid straw stems are pressed into sheets by a pressing machine, and ...

Embodiment 1

[0037] In this embodiment, taking the manufacture of a straw-wound composite pipe with a nominal diameter of 200 mm as an example, the preparation method of the straw-wound composite pipe of the present invention is specifically described, and the specific steps are as follows:

[0038] 1) Straw pretreatment:

[0039] Select one or more of wheat, rice, corn, sorghum straw, remove the rest of the straw except the stem, dry the straw stem to obtain a straw stem with a moisture content of 10%, and then cut it into the same length .

[0040] 2) Preparation of the lining layer:

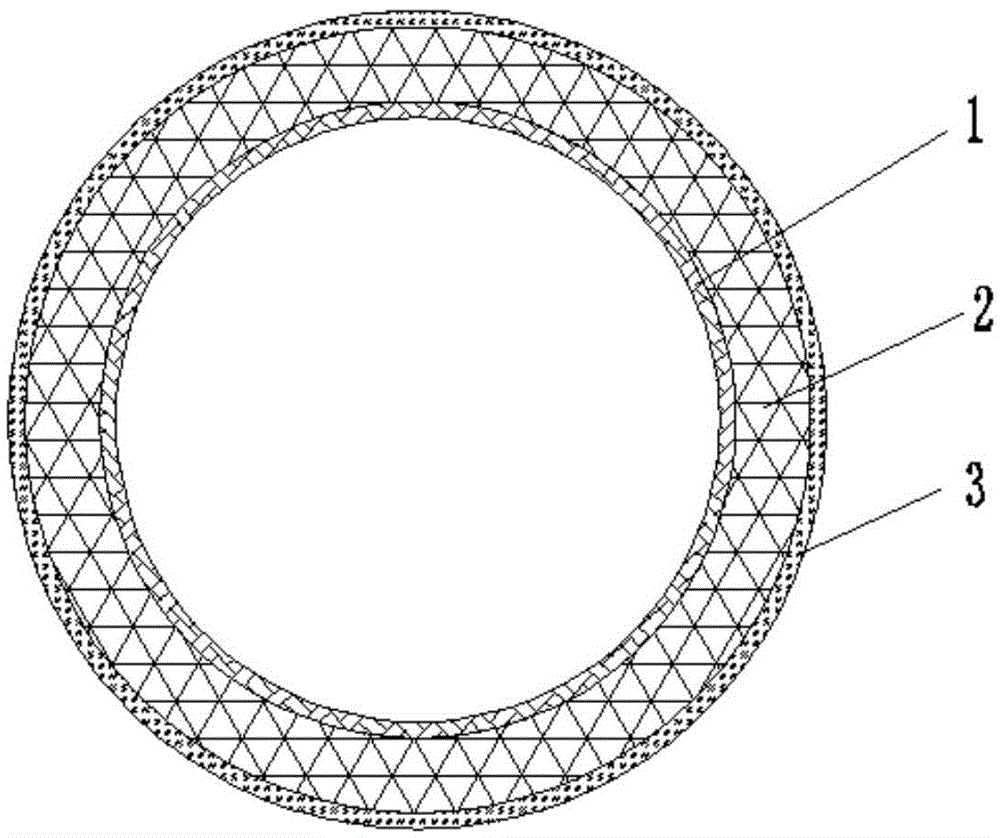

[0041] A 0.04mm thick polyester film is coated on a polished straight tube mold with an outer diameter of 200mm. An inner lining layer 1 with a thickness of 1.5 mm is made on the release layer of the pipe mold. The inner lining layer has an anti-seepage function and has a smooth inner wall; Cloth and glass fiber knitted mat, wood fiber non-woven fabric as natural fiber fabric layer, glass fiber knitted ...

Embodiment 2

[0048] In this embodiment, taking the production of a straw bamboo winding composite pipe with a nominal diameter of 400 mm as an example, the preparation method of the straw bamboo winding composite pipe of the present invention is specifically described, and the specific steps are as follows:

[0049] 1) straw pretreatment: with embodiment 1;

[0050] 2) preparation of inner liner: with embodiment 1, just the outer diameter of straight pipe mold is 400mm;

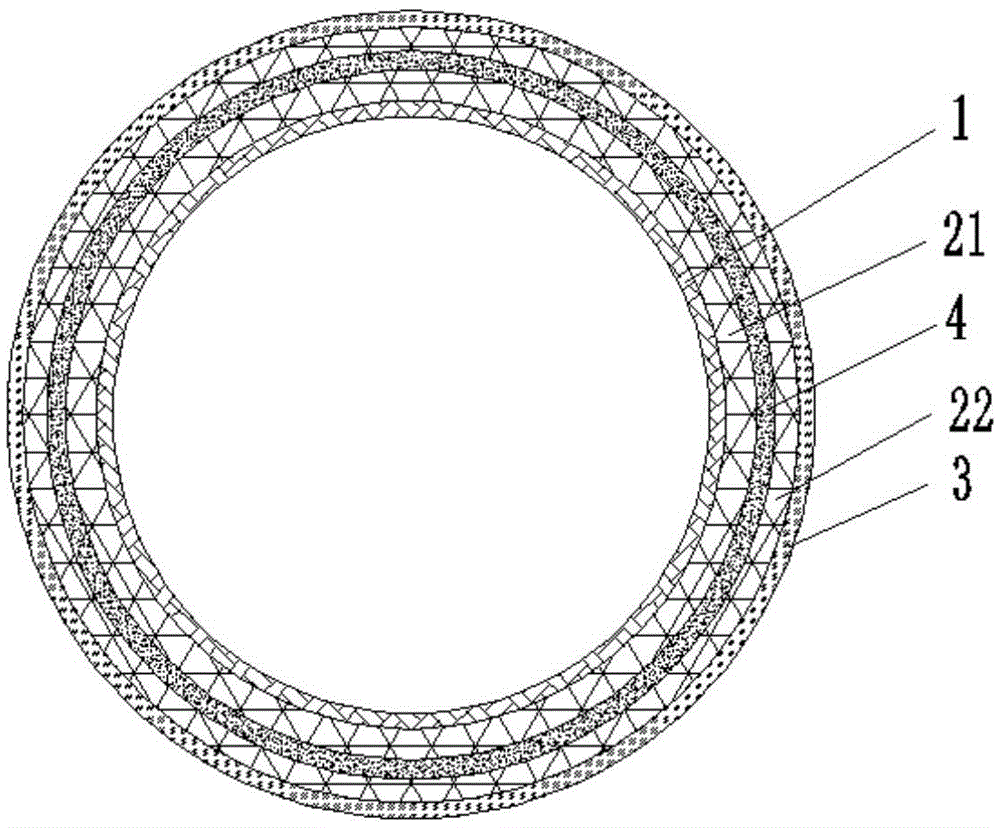

[0051] 3) Preparation of the first straw reinforcement layer 21: same as in Example 1, with a thickness of 6 mm;

[0052] 4) Preparation of auxiliary reinforcement layer:

[0053] Use resin and inorganic mineral fillers or natural plant fillers to mix and stir into cement. The inorganic mineral fillers can be selected from stone powder, ore sand, etc., and the natural plant fillers can be selected from one of wood chips, wood powder, bamboo chips, bamboo powder, and plant shell powder. Several kinds, the filler mass rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com