On-line monitoring system of coal characteristics of as-fired coal

A monitoring system and characteristic technology, which is applied in the field of online monitoring system of coal quality characteristics of incoming coal, can solve the problems of increased maintenance, limited adaptability, a large number of mechanical moving parts, etc., and achieves the effect of simple structure and synchronous measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

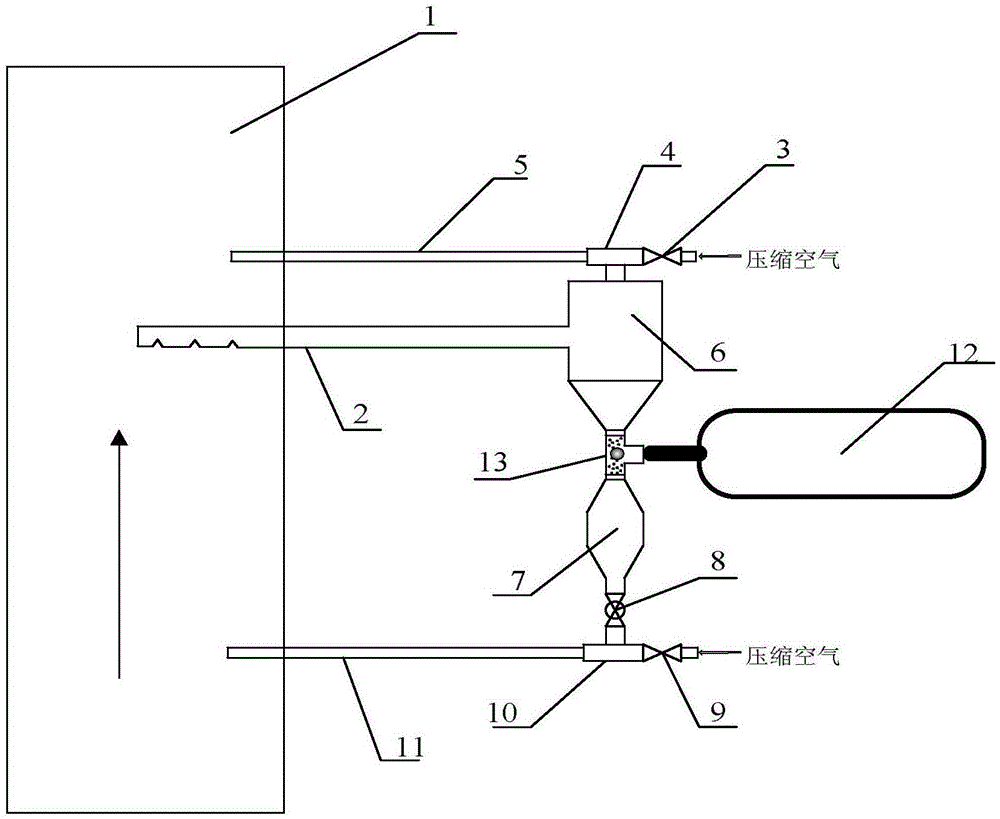

[0024] like figure 1 As shown, an on-line monitoring system for coal quality characteristics of incoming coal includes a sampling unit, a plasma spectroscopic analysis unit 12, a sample storage unit, a three-way particle flow measurement unit and a sample return unit,

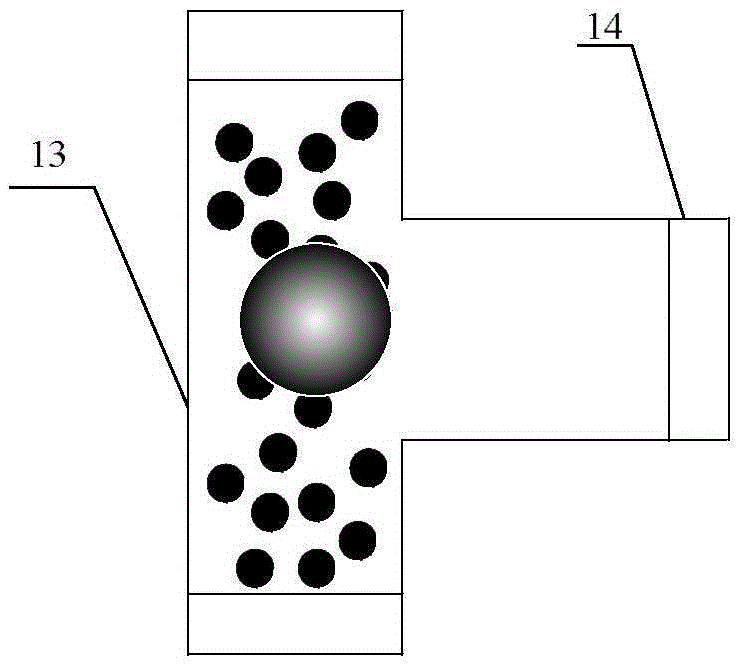

[0025] One end of the sampling unit is connected to the pulverized coal pipeline 1, and the other end is connected to an interface of the three-way particle flow measurement unit; the plasma spectrum analysis unit 12 is connected to the other end of the three-way particle flow measurement unit. The interface is used to excite the pulverized coal particle flow in the three-way particle flow measurement unit to form plasma, collect plasma spectral signals, process and analyze the plasma signal to obtain the coal quality characteristics of the furnace coal, and the coal quality characteristics include elements One or any combination of analysis, industrial analysis, heat value, ash composition, slagging characteri...

Embodiment 2

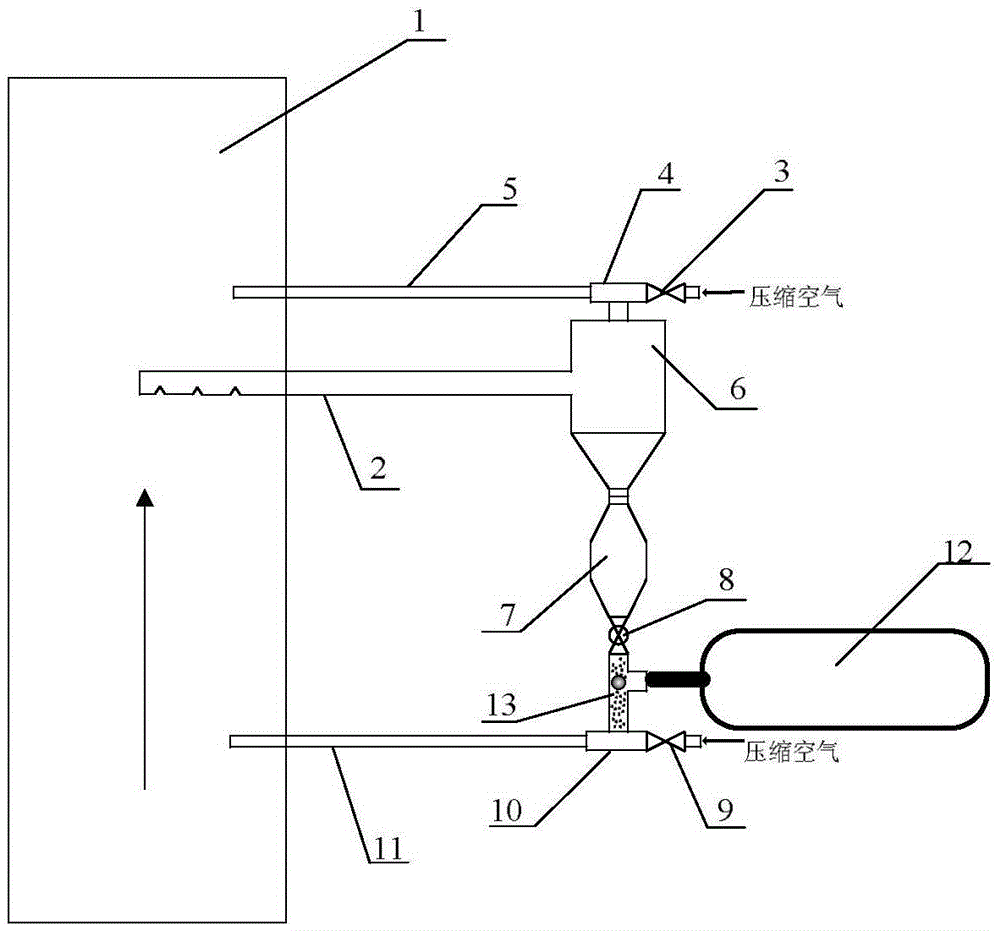

[0034] like image 3 As shown, compared with Example 1, the difference of Example 2 is that the sample storage unit is connected between the sampling unit and the three-way particle flow measurement unit, that is, the position of the three-way particle flow measurement unit is adjusted. Adjust and connect the three-way particle flow measurement unit under the sample storage unit.

[0035]The first solenoid valve 3 controls the flow of compressed air entering the sampling unit to control the amount of pulverized coal sampling; the pneumatic valve 8 controls the amount of sample entering the three-way particle flow measurement unit. , the pneumatic valve 8 connected to the sample storage bin 7 is opened, and the sample falls freely, thereby ensuring that the downstream density of the sample entering the three-way particle flow measurement unit is large enough and the sample downstream flow rate is relatively stable.

[0036] The plasma spectroscopic analysis unit described in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com