Oxidizing agent and ultraviolet light cooperating organic waste gas purification device and processing method

A technology of organic waste gas and oxidant, applied in gas treatment, chemical instruments and methods, separation methods, etc., can solve problems such as difficulty, low efficiency, VOCs pollution solution, etc., to achieve simple operation, overcome organic waste gas, and good humidification effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

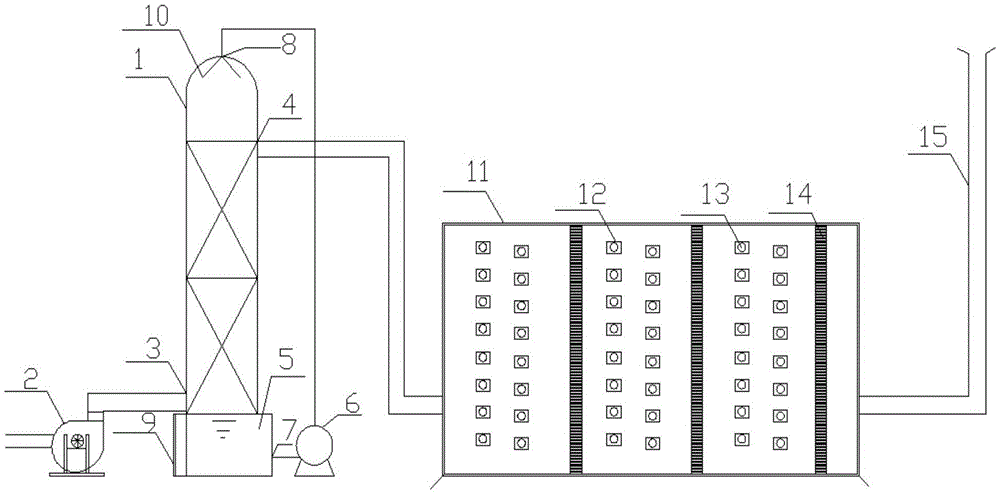

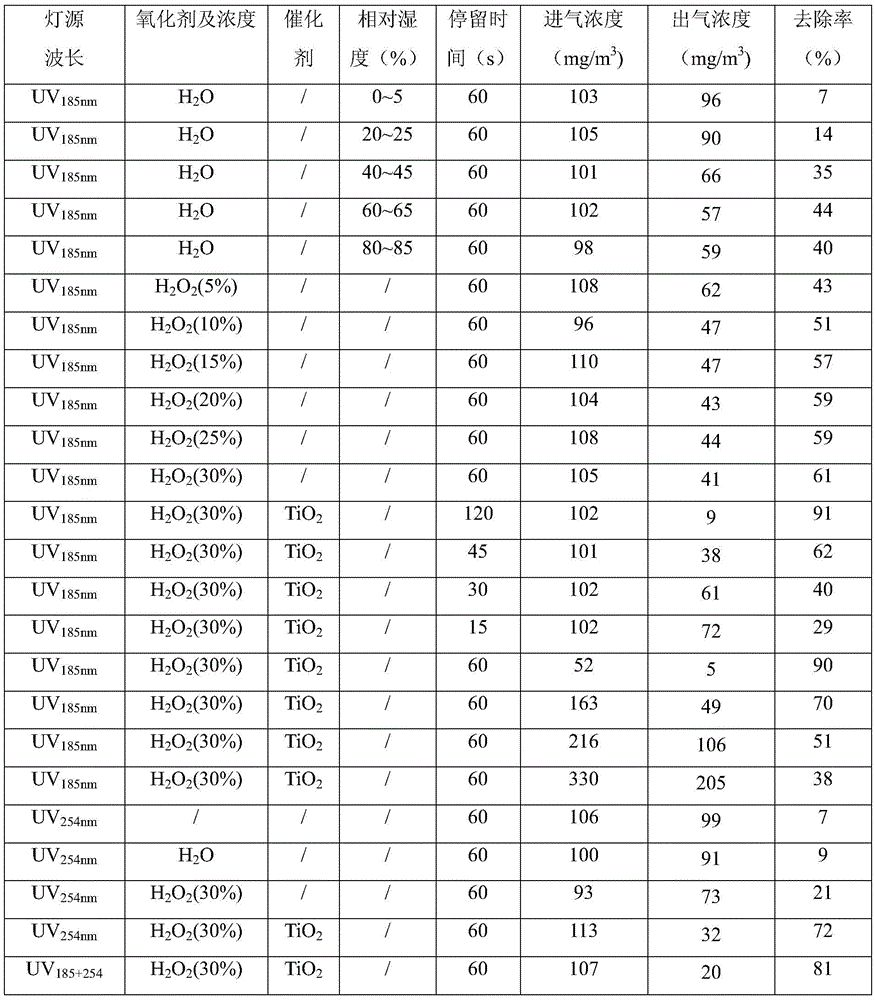

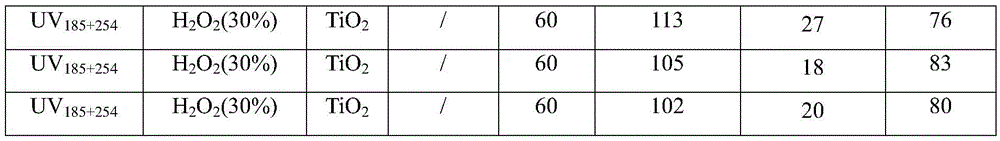

[0028] In this embodiment, the humidifying device is a humidifying tower made of polypropylene with a height of 5m and a diameter of 1.5m; the oxidant liquid storage tank is 1m high and has a volume of 2m 3 ; The waste gas induced draft fan, the humidifying device and the ultraviolet light reactor are connected by a waste gas pipeline, and the described waste gas pipeline is a DN300 air duct made of polypropylene; the described air inlet is 20 cm away from the bottom of the humidifying tower; the described The flow rate of the high pressure pump is 3m 3 / h, the flow rate is controlled by a ball valve; the volume of the ultraviolet light reactor is 10m 3 The ultraviolet lamps are regularly arranged, and three combinations are set, and the wavelengths of the ultraviolet lamp groups of each combination are different, wherein the wavelength of one row of ultraviolet lamp groups is 185nm, and the wavelength of another row is 254nm; the number of the catalyst filter screen is 3 she...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com