Magnetic microsphere capable of absorbing cadmium ions and complexes thereof, as well as preparation method, application method and regeneration method of magnetic microsphere

A technology of magnetic microspheres and complexes, which is applied in separation methods, filter regeneration, alkali metal compounds, etc., can solve the problem that the adsorption capacity of cadmium ions is difficult to meet the expected requirements, and the regeneration cycle capacity of ferric tetroxide magnetic adsorption materials is poor. Cumbersome operation and other problems, to achieve the effect of rich carboxyl group content, beneficial adsorption efficiency, and simplified preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

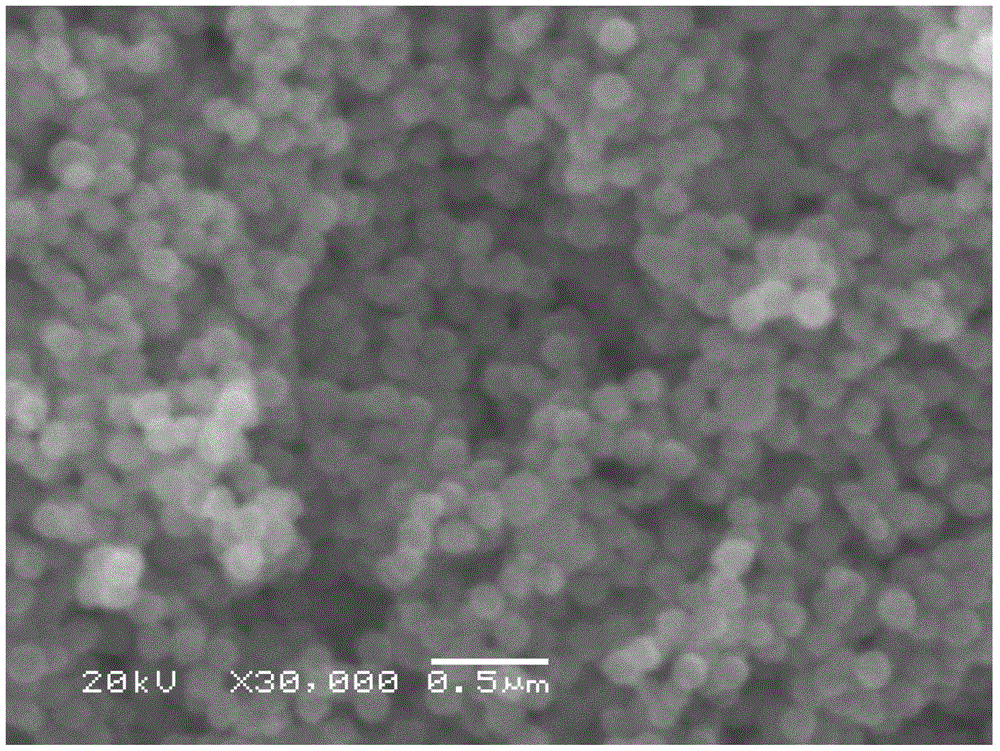

[0034] A magnetic microsphere adsorbed by cadmium ions and their complexes of the present invention, with magnetic nano-ferric oxide particles as the core, coated with polyacrylic acid on the surface of the magnetic nanoparticles to form a ferric oxide / polyacrylic acid composite material, The surface of the ferroferric oxide / polyacrylic acid composite material is grafted with 4-phenyl-3-thiosemicarbazide; the average particle size of the magnetic microspheres is about 100nm, and the specific surface area is about 120m 2 / g.

[0035] The preparation method of the magnetic microspheres adsorbed by cadmium ions and their complexes of the present embodiment comprises the following steps:

[0036] (1) Dissolve iron acetylacetonate in ethylene glycol so that the concentration of ferric ion is 0.1mol / L, then add sodium acrylate, sodium acetate, and ethylenediamine solution (ethylenediamine The volume of the solution is 5% of the whole solution volume), mixed and stirred to obtain a ...

Embodiment 2

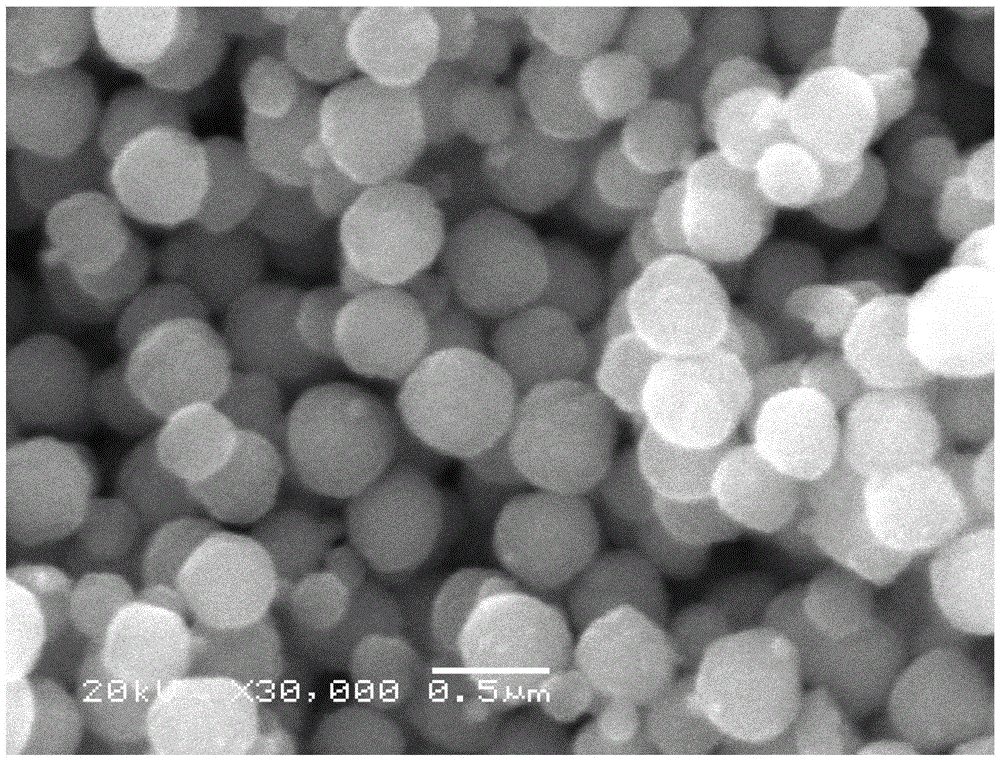

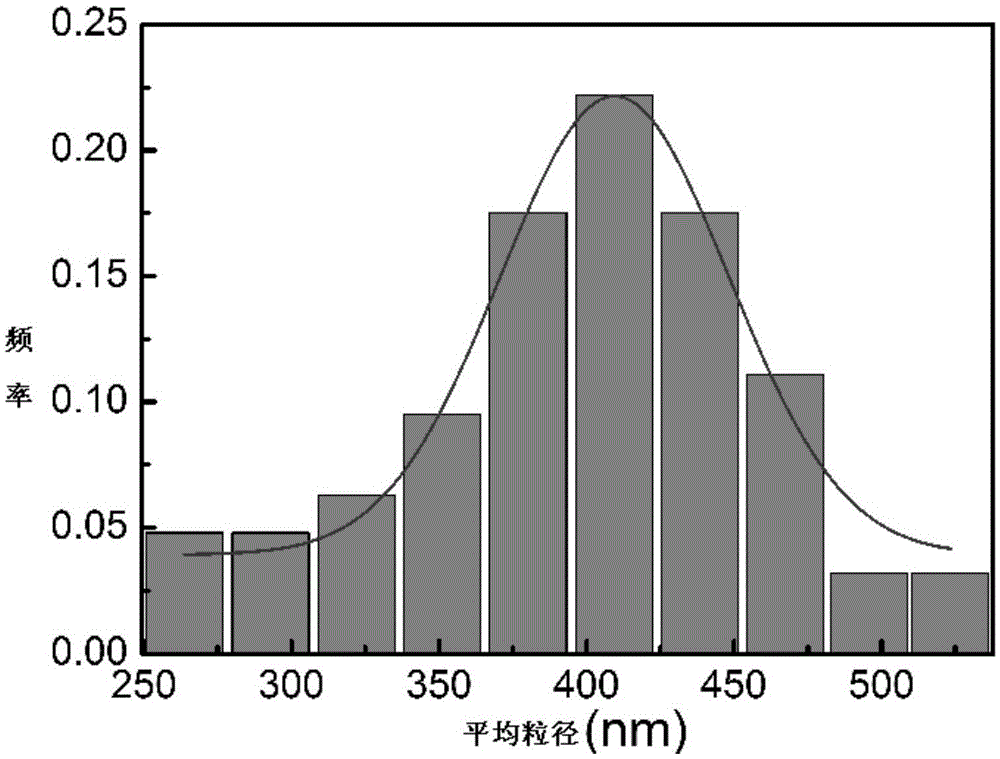

[0041] A magnetic microsphere adsorbed by cadmium ions and their complexes of the present invention, with magnetic nano-ferric oxide particles as the core, coated with polyacrylic acid on the surface of the magnetic nanoparticles to form a ferric oxide / polyacrylic acid composite material, The surface of the ferroferric oxide / polyacrylic acid composite material is grafted with 4-phenyl-3-thiosemicarbazide; the particle size of the magnetic microspheres is about 400nm, and the specific surface area is about 80m 2 / g.

[0042] The preparation method of the magnetic microspheres adsorbed by cadmium ions and their complexes of the present embodiment comprises the following steps:

[0043] (1) Dissolve ferric chloride in ethylene glycol so that the concentration of ferric ions is 0.1mol / L, and then add sodium acrylate, sodium acetate, and ethylenediamine solution (ethylenediamine) with a mass ratio of 1:2 in sequence. The volume of the amine solution is 2% of the total solution vol...

Embodiment 3

[0049] A magnetic microsphere adsorbed by cadmium ions and their complexes of the present invention, with magnetic nano-ferric oxide particles as the core, coated with polyacrylic acid on the surface of the magnetic nanoparticles to form a ferric oxide / polyacrylic acid composite material, The surface of the ferroferric oxide / polyacrylic acid composite material is grafted with 4-phenyl-3-thiosemicarbazide; the particle size of the magnetic microspheres is about 150nm, and the specific surface area is about 108cm 3 / g.

[0050] The preparation method of the magnetic microspheres adsorbed by cadmium ions and their complexes of the present embodiment comprises the following steps:

[0051] (1) Dissolve ferric chloride hexahydrate in ethylene glycol so that the concentration of ferric ion is 0.1mol / L, then add sodium acrylate, sodium acetate, and ethylenediamine solution with a mass ratio of 2:1 in sequence ( The volume of the ethylenediamine solution is 5% of the whole solution v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com