Catalyst for hydrogen production from steam reforming of methanol and preparation method thereof

A steam reforming and catalyst technology, which is applied in catalyst activation/preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as poor catalytic effect of catalysts and achieve high catalytic performance Activity and stability, increased contact interface, easy industrial scale-up effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

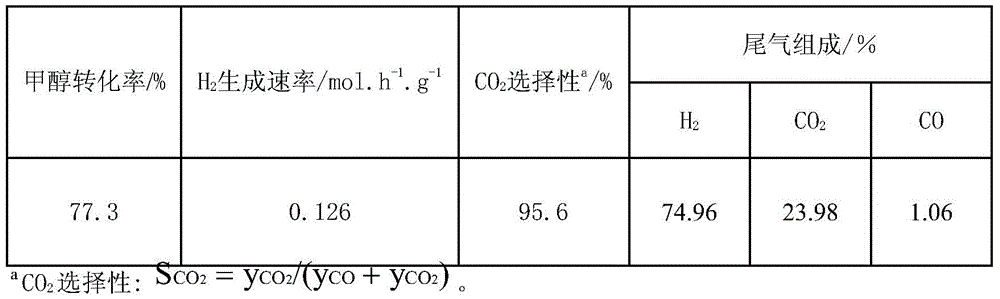

Embodiment 1

[0022] A catalyst for steam reforming of methanol to produce hydrogen, which is prepared by step-by-step precipitation, that is, the copper component is precipitated in the first step, and the zirconium component is precipitated in the second step. The mole percentage of each metal atom contained in the catalyst is calculated, details as follows:

[0023] Cu88.9%

[0024] Zr11.1%.

[0025] Above-mentioned a kind of preparation method for hydrogen production by steam reforming of methanol specifically comprises the following steps:

[0026] 1) 357mL of 0.7mol / L Cu(NO 3 ) 2 Solution I and 0.4mol / L Na 2 CO 3 Solution II was added dropwise to 50mL of 0.2mol / L Na 2 CO 3 In beaker III of the solution, and control the amount of each drop of co-current to 0.05-0.07ml, by adjusting 0.5mol / L Na 2 CO 3 The dropping rate of solution II uses a pH meter to control the pH value of the suspension within the range of 7.3-7.8. During the dropping process, the stirring speed is controll...

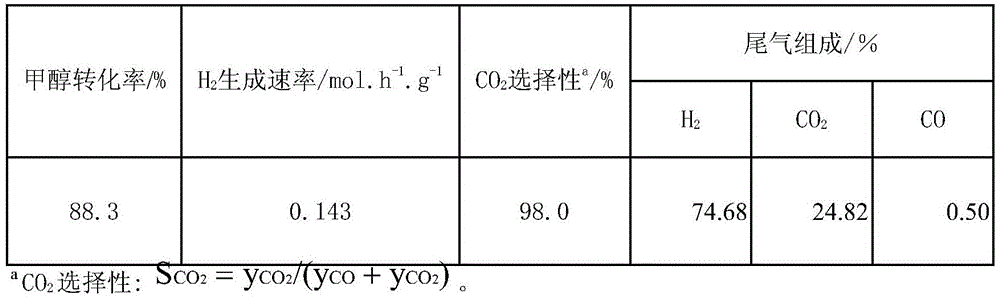

Embodiment 2

[0030] A catalyst for steam reforming of methanol to produce hydrogen, which is prepared by step-by-step precipitation, that is, the copper component is precipitated in the first step, and the zirconium component is precipitated in the second step. The mole percentage of each metal atom contained in the catalyst is calculated, details as follows:

[0031] Cu80%

[0032] Zr20%.

[0033] Above-mentioned a kind of preparation method for hydrogen production by steam reforming of methanol specifically comprises the following steps:

[0034] 1) Add 190mL of 1.3mol / L Cu(NO 3 ) 2 Solution I and 0.6mol / L Na 2 CO 3 Solution II was added dropwise to 50mL of 0.2mol / L Na 2 CO 3 In beaker III of the solution, and control the amount of each drop of co-current to 0.05-0.07ml, by adjusting 0.5mol / L Na 2 CO 3 The drop rate of solution II adopts pH meter to control the pH value of the suspension in the range of 7.3-7.8, and the stirring speed is controlled to be 200-300r / min during the ...

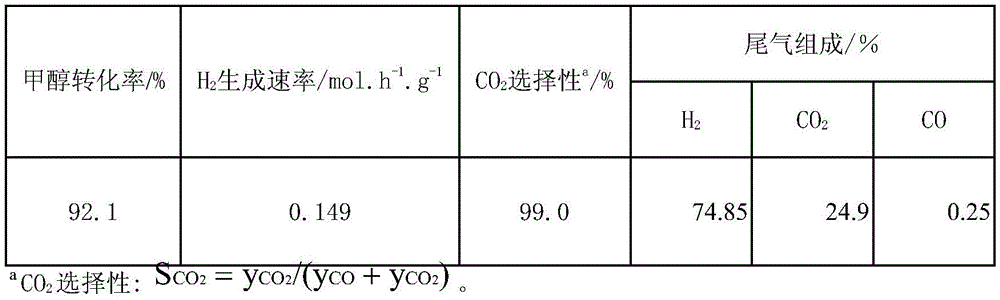

Embodiment 3

[0038] A catalyst for steam reforming of methanol to produce hydrogen, which is prepared by step-by-step precipitation, that is, the copper component is precipitated in the first step, and the zirconium component is precipitated in the second step. The mole percentage of each metal atom contained in the catalyst is calculated, details as follows:

[0039] Cu72.7%

[0040] Zr27.3%.

[0041] Above-mentioned a kind of preparation method for hydrogen production by steam reforming of methanol specifically comprises the following steps:

[0042] 1) 250mL of 1mol / L Cu(NO 3 ) 2 Solution I and 0.5mol / L Na 2 CO 3 Solution II was added dropwise to 50mL of 0.2mol / L Na 2 CO 3 In beaker III of the solution, and control the amount of each drop of co-current to 0.05-0.07ml, by adjusting 0.5mol / L Na 2 CO 3 The drop rate of solution II adopts pH meter to control the pH value of the suspension in the range of 7.3-7.8, and the stirring speed is controlled to be 200-300r / min during the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com