Welding seam alloy and welding method of weather-resistant steel

A welding method and weathering steel technology are applied in the welding field of weathering steel welding suture and weathering steel, which can solve the problems of corrosion resistance and mechanical strength performance mismatch, and obstacles to the application and promotion of weathering steel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

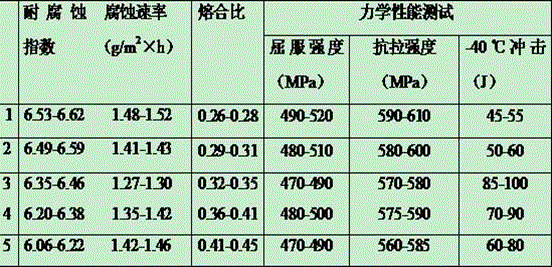

Examples

Embodiment 1

[0053] A welding method of weathering steel, selecting 6mm ASTM A871GR65 weathering steel and JM-55Ⅱ welding wire as raw materials, including the formation of welding seam gold:

[0054] Groove polishing: control the gap at the root of the groove to 0.6mm, and polish both sides of the adjacent area of the groove to expose the metal luster of the groove;

[0055] Spot welding assembly: tack welding is performed on the polished groove, the length of each tack welding point is controlled to 6mm, the distance between each two tack welding points is 200mm, the welding wire used for tack welding is JM-55Ⅱ welding wire , Tack welding is carried out under shielding gas protection;

[0056] Preheating before welding: After spot welding and assembly, preheat the groove and set the preheating temperature to 73℃;

[0057] Formation of the bottom welding layer: welding the preheated groove under the condition of shielding gas to form the bottom welding layer composed of the first weld pass;

[00...

Embodiment 2

[0062] This embodiment is basically the same as embodiment 1, but the differences are:

[0063] The thickness of the raw material ASTMA871GR65 weathering steel is 9mm.

Embodiment 3

[0065] This embodiment is basically the same as Embodiment 2, but the differences are:

[0066] The thickness of the raw material ASTMA871GR65 weathering steel is 15mm. In the preparation of the groove, the gap between the root of the groove is controlled to 1.8mm, and six steps are added between the temperature measurement between the bottom weld layer and the formation of the cover layer. :

[0067] Formation of the second weld bead of the filling layer: Under the condition of shielding gas, weld the groove that has passed the temperature detection between the passes to form the second weld bead;

[0068] Interpass grinding of the filling layer: grinding the second weld bead in the filling layer to remove the slag and pores generated after the formation of the second weld bead;

[0069] Interpass temperature measurement of the filling layer: measure the interpass temperature of the second weld bead of the filling layer. When the interpass temperature falls within the range of 140℃-1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com