Fracturing flowback fluid biological treatment method based on BESI, aerobiotic suspended packing and single-hole membrane method

A fracturing flowback fluid and suspended filler technology, applied in the field of oilfield sewage treatment, can solve the problems of low effluent quality, membrane pollution treatment cost, etc., and achieve stable treatment effect, reduced treatment cost, and strong anti-pollution impact load capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

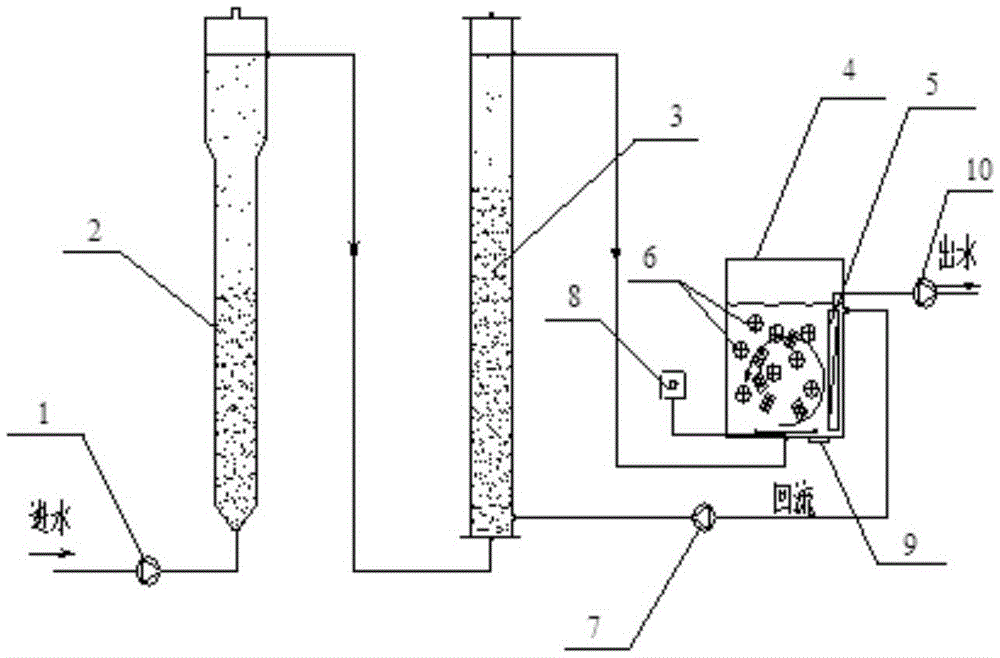

[0025] Specific Embodiments 1. In this embodiment, a biological treatment method for fracturing flowback fluid based on BESI+aerobic suspension filler+single-hole membrane method, the fracturing flowback fluid reaction device involved mainly includes: sewage water inlet pump 1, Anaerobic reaction device 2, facultative anaerobic reaction device 3, aerobic reaction device 4, single-hole membrane module 5, aerobic suspension packing 6, reflux pump 7, aeration device 8, sludge outlet 9 and peristaltic pump 10 The sewage inlet pump 1 is connected to the bottom water inlet of the anaerobic reaction device 2, and the top side wall water outlet of the anaerobic reaction device 2 is connected to the bottom water inlet of the facultative anaerobic reaction device 3, and the facultative anaerobic reaction device 3 The water outlet on the top side wall is connected to the bottom water inlet of the aerobic reaction device 4, the single-hole membrane module 5 and the aerobic suspension fille...

specific Embodiment approach 2

[0037] Specific embodiment 2. This embodiment is a further description of the biological treatment method for fracturing flowback fluid based on BESI + aerobic suspension filler + single-hole membrane method described in specific embodiment 1. The anaerobic reaction described in step 1 Device 2 is a UASB anaerobic reaction device, an ABR anaerobic reaction device, an IC anaerobic reaction device or an SBR anaerobic reaction device.

specific Embodiment approach 3

[0038] Specific embodiment three. This embodiment is a further description of the biological treatment method for fracturing flowback fluid based on BESI + aerobic suspension filler + single-hole membrane method described in specific embodiment one or two. The oxygen reaction device 2 is filled with suspended fillers for anaerobic use, and the filling ratio is 30-50% by volume, wherein the suspended fillers for anaerobic use are black polyurethane with a size of 4×4×4 cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Porosity | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com