Production process and system of calcium hydroxide

A technology of calcium hydroxide and production process, which is applied in the field of calcium hydroxide preparation, can solve the problems of many impurities, and achieve the effects of high utilization rate, high purity and whiteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific drawings and specific embodiments.

[0035] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

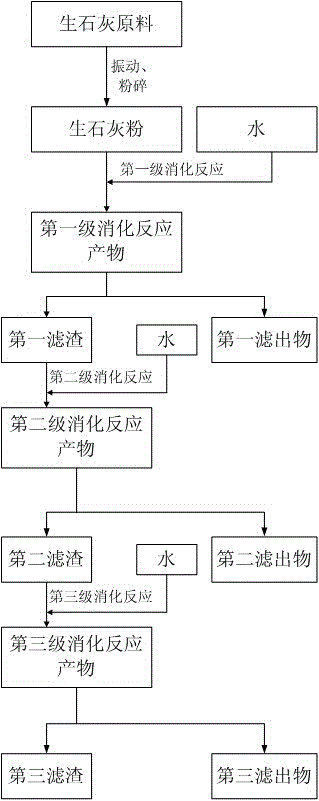

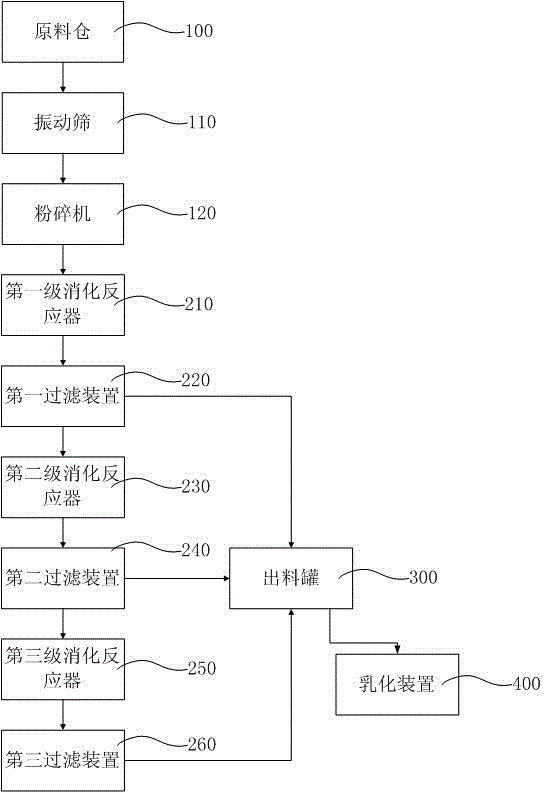

[0036] see figure 1 , a calcium hydroxide production process, it comprises the steps:

[0037] S100: Raw material processing: Vibrating the quicklime raw material and then pulverizing it to obtain quicklime powder; vibrating the quicklime raw material can disperse the quicklime raw material to facilitate the subsequent crushing treatment, and the quicklime powder obtained after the quicklime crushing treatment has a particle size The diameter is 1~10 microns;

[0038] S200: Digestion reaction: mix the quicklime powder and water evenly and completely to perform a digestion re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com