Method for preparing high-purity and high-yield pyrophosphoric acid piperazine and application thereof

A high-purity technology of piperazine pyrophosphate, applied in the field of preparation of piperazine pyrophosphate, can solve problems such as high price of raw materials, inability to be widely used, insufficient performance of finished products, etc., and achieves avoiding the interference of sodium ions, avoiding incomplete risks, Responsive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

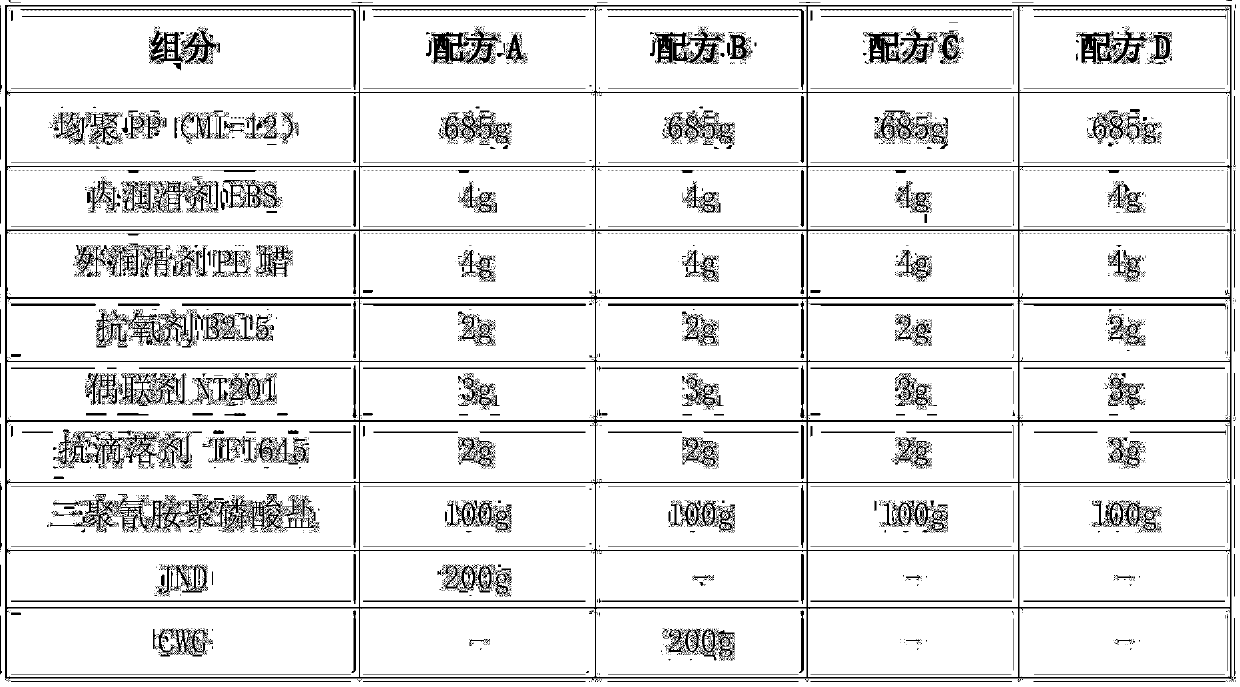

Embodiment 1

[0048] In a 100L reactor with a stirring and refluxing device, add 11.55kg of phosphorus pentoxide, add 9.38kg of 85% phosphoric acid dropwise while stirring, and after the dropwise addition is completed, the temperature of the reactor is controlled to 200±5°C, and this temperature is maintained for 1h .

[0049] Then cool down to 80±5℃, add 63kg of glacial acetic acid to the reaction kettle, after stirring for 0.5h, add anhydrous piperazine in batches, add a total of 10.5kg, after adding, maintain the reflux state of the reaction solution and keep the temperature at 115 -120℃, time 2h.

[0050] After that, it was cooled to room temperature and filtered until no obvious liquid dripped. The filter cake was put into a vacuum rake dryer. The temperature of the heat transfer oil was set at 185±5℃, the vacuum degree was kept at 0.05±0.02Mpa, and the drying time was 3h. smash.

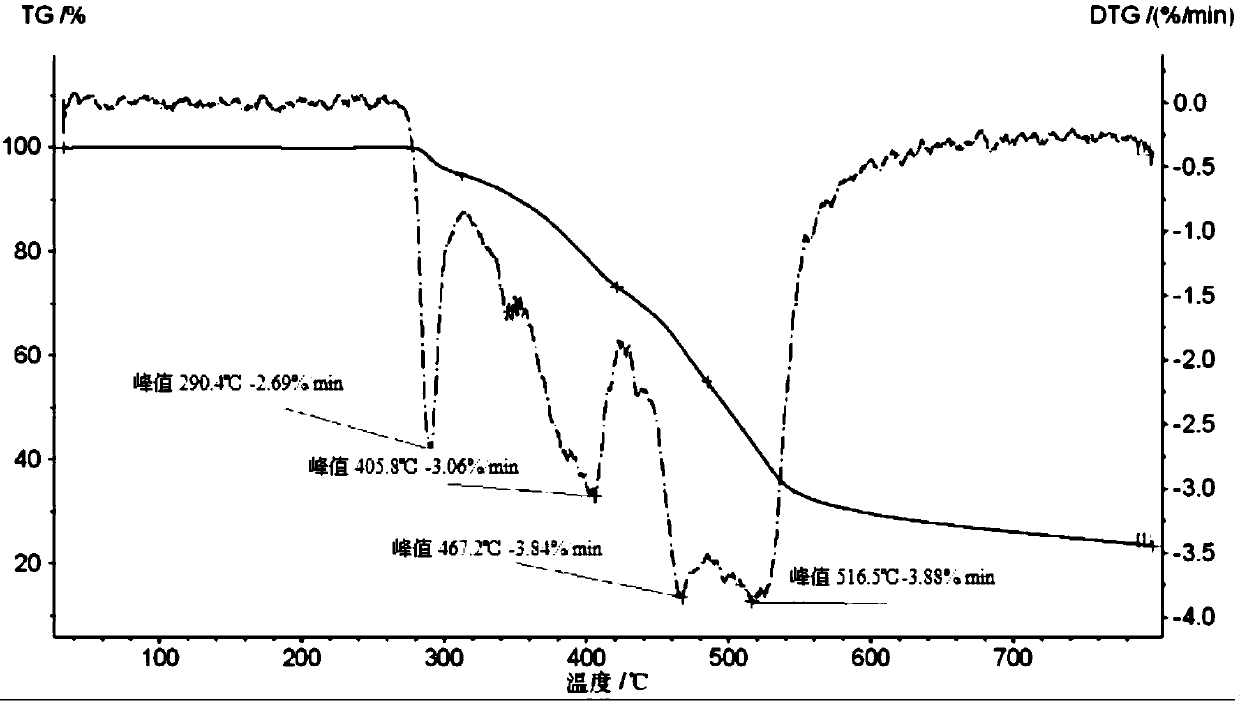

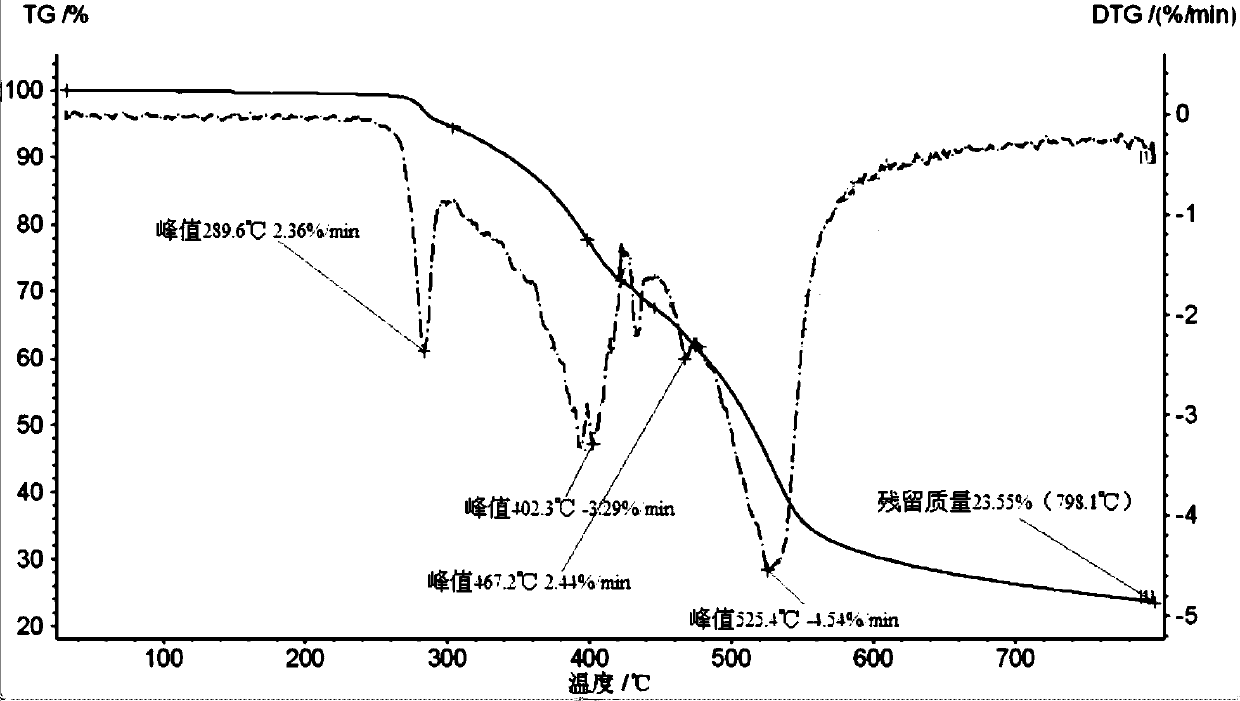

[0051] 31.10kg of product can be obtained, yield 96.49%, purity 99.2%, moisture 0.1%, whiteness 94%, pa...

Embodiment 2

[0053] In a 500L reaction kettle with stirring and reflux device, add 56.83kg of phosphorus pentoxide, add 46.15kg of 85% phosphoric acid dropwise while stirring, and dropwise add to it. h.

[0054] Then the temperature was lowered to 80±5°C, 310kg of glacial acetic acid was added to the reaction kettle, and after stirring for 0.5h, anhydrous piperazine was added in batches, and a total of 52.1kg was added. -120℃, time 3h.

[0055] After that, it was cooled to room temperature, filtered until no obvious liquid dripped, and the filter cake was put into a vacuum rake dryer. machine crushing.

[0056] 151.50kg of product can be obtained, yield 95.52%, purity 99.1%, moisture 0.1%, whiteness 95%, particle size D 50 = 8.14 μm, D 98 =18.38μm, high-purity piperazine pyrophosphate with initial decomposition temperature ≥280°C.

Embodiment 3

[0058] In the 1000L reactor with stirring and refluxing device, add 113.66kg of phosphorus pentoxide, add 92.3kg of 85% phosphoric acid dropwise while stirring, and dropwise add to control the temperature of the reactor at 202±5°C, keeping this temperature at 1.5 h.

[0059] Then cool down to 80±5℃, add 600kg of glacial acetic acid to the reaction kettle, after stirring for 0.5h, add anhydrous piperazine in batches, add 104.2kg in total, after adding, maintain the reflux state of the reaction solution, keep the temperature at 116 ~120℃, time 3.5h.

[0060] Then cool down to room temperature, filter by pressure until no obvious liquid drips, put the filter cake into the vacuum rake dryer, set the temperature of the heat transfer oil to 188±5℃, keep the vacuum degree at 0.05±0.03Mpa, and the drying time is 4h. The product uses a jet mill. smash.

[0061] 301.68kg of product can be obtained, yield 95.10%, purity 99.2%, moisture 0.1%, whiteness 94%, particle size D 50 = 8.12 μm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com