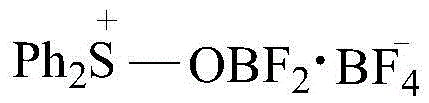

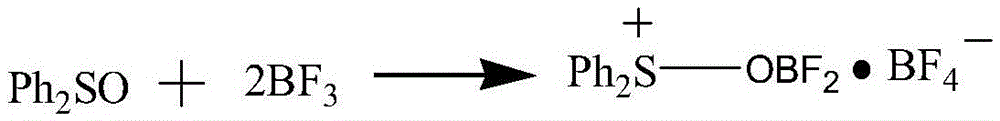

Preparation method for boron difluoride diphenyl sulphur tetrafluoroborate compound

A technology of difluorooxyboron diphenylpyrurium tetrafluoroboric acid and compounds, which is applied in the field of preparation of difluorooxyboron diphenylpyrurium tetrafluoroboric acid compounds, can solve problems such as not existing, and achieve simple preparation process and high reaction product High yield and good product stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

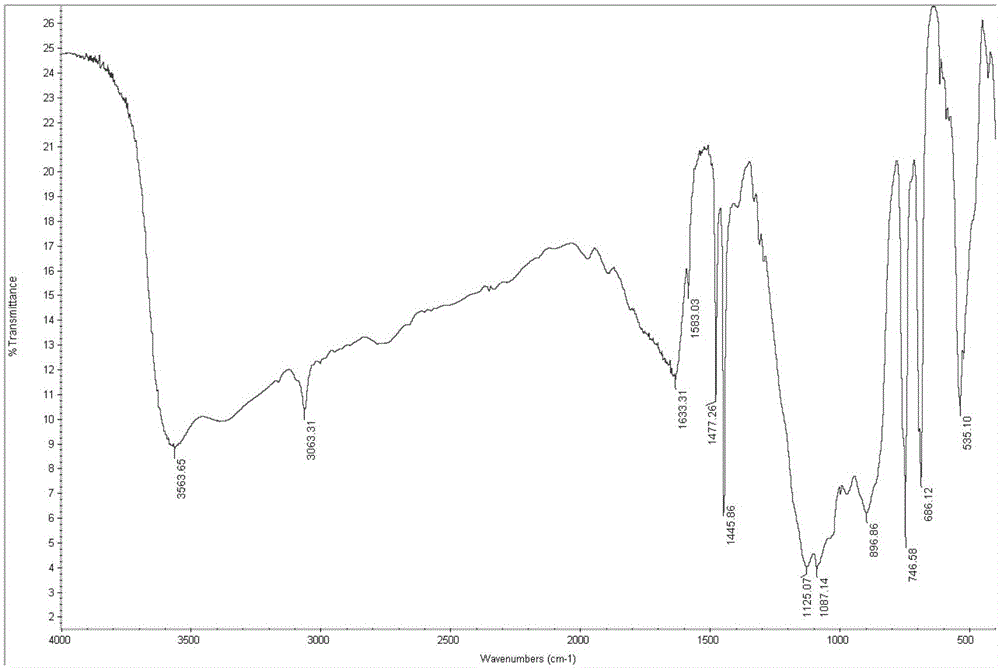

[0020] Add 5ml of toluene and 0.0005mol of diphenyl sulfoxide to a three-necked flask equipped with a stirring bar to dissolve them, and then add 0.001mol of BF 3 Diethyl ether solution, keep the solution temperature not exceeding 20°C, stir for 20 minutes, add 20ml of n-heptane to precipitate, and separate the liquid with a separatory funnel to obtain a brown liquid in the lower layer, with a yield of 95%.

[0021] figure 1 Infrared image of the target product.

Embodiment 2

[0023] Add 5ml of benzene and 0.0005mol of diphenyl sulfoxide to a three-necked flask equipped with a stirring bar to dissolve them, and then add 0.001mol of BF 3 Diethyl ether solution, keep the solution temperature at 25° C., stir for 15 minutes, add 15 ml of n-heptane to precipitate, and separate the liquid with a separatory funnel to obtain a brown liquid in the lower layer, with a yield of 93%.

Embodiment 3

[0025] Add 5ml of toluene and 0.0005mol of diphenyl sulfoxide to a three-necked flask equipped with a stirring bar to dissolve them, and then add 0.001mol of BF 3 Diethyl ether solution, keep the solution temperature at 15° C., stir for 30 minutes, add 25 ml of n-hexane to precipitate, and separate the liquid with a separatory funnel to obtain a brown liquid in the lower layer, with a yield of 96%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com