Medium/high-solid hydroxy acrylic resin and preparation method thereof

A hydroxyacrylic acid, high-solid technology, applied in the direction of coating, etc., can solve the problems of lack of hardness and other physical properties, poor solvent release, high price of fluorine-containing monomers, etc., to achieve excellent corrosion resistance, excellent weather resistance, excellent The effect of physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

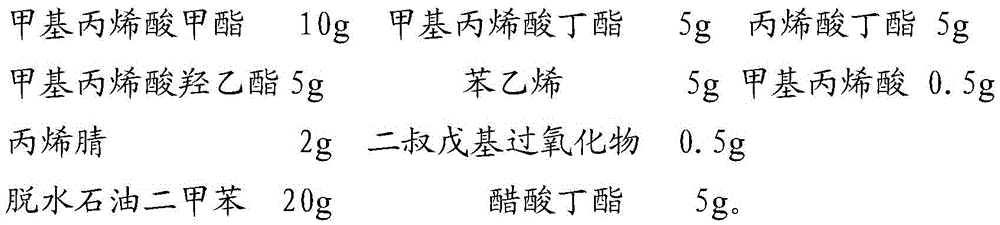

Embodiment 1

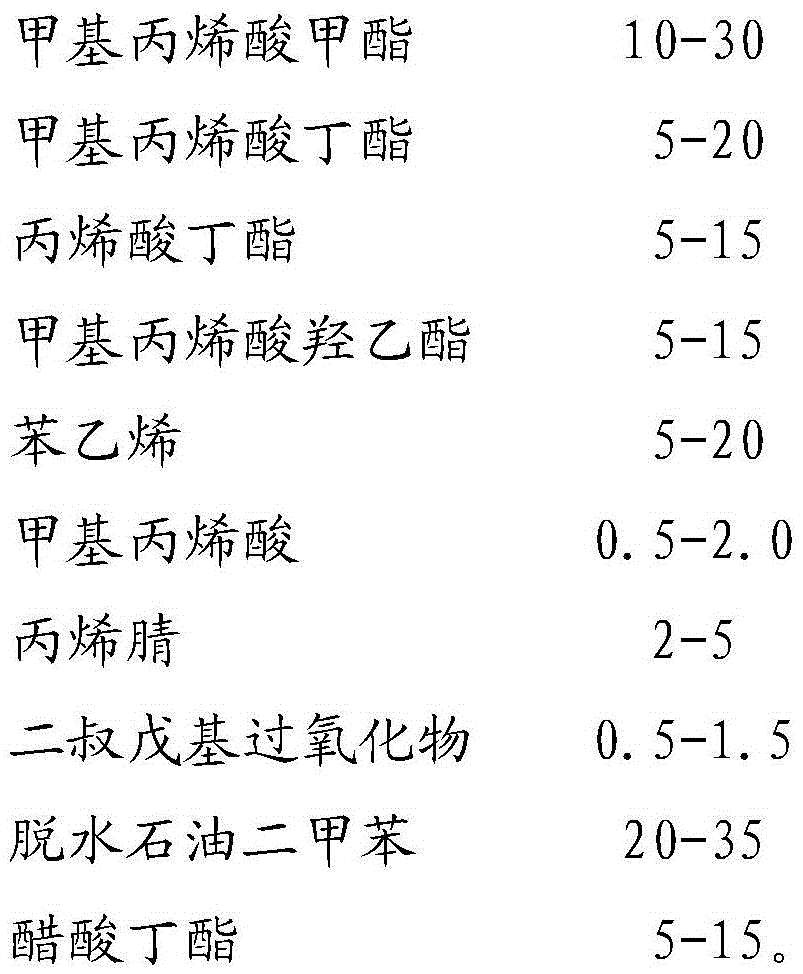

[0021] A medium to high solids hydroxyl acrylic resin comprising the following components, in grams by weight

[0022]

[0023] The preparation method of above-mentioned middle and high solid hydroxyl acrylic resin, carries out according to the following steps,

[0024] (1) in the four-necked flask that condenser, agitator, dropping funnel and thermometer are equipped with, add two kinds of solvents of dehydrated petroleum xylene and butyl acetate of formula amount 90%;

[0025] (2) Feed in nitrogen and heat up to the reflux temperature (130±2)°C;

[0026] (3) After refluxing for 10 minutes, first add acrylonitrile monomer into the four-necked flask, and then add methyl methacrylate, butyl methacrylate, butyl acrylate, hydroxyethyl methacrylate, styrene and Various monomers of methacrylic acid and 60% di-tert-amyl peroxide are mixed in a beaker and packed into a dropping funnel, and are evenly added dropwise to the flask at a speed of 6 g / min. From the beginning of droppin...

Embodiment 2

[0034] A medium to high solids hydroxyl acrylic resin comprising the following components, in grams by weight

[0035]

[0036] The preparation method of the medium-high solid hydroxyl acrylic resin is carried out according to the steps in Example 1.

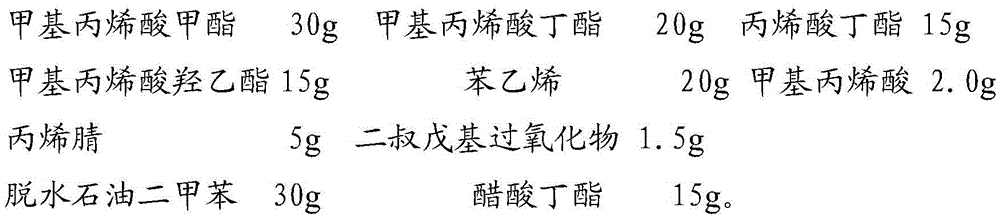

Embodiment 3

[0038]A medium to high solids hydroxyl acrylic resin comprising the following components, in grams by weight

[0039]

[0040] The preparation method of the medium-high solid hydroxyl acrylic resin is carried out according to the steps in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com