A lactic acid-based aliphatic-aromatic random copolymer

A technology of random copolymer and lactic acid base grease, which is applied in the field of polymers, can solve the problems of reducing the brittleness of polylactic acid, reducing the complex viscosity, and reducing the melt strength, etc., to achieve improved compatibility, good elongation at break, high The effect of melt strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0118] 1.1 Add 1,800g of lactic acid and 1,000g of succinic anhydride to the flask in turn, raise the temperature to 140°C, and stir the reactants. After 10 hours, raise the temperature to 180°C, and remove the unreacted monomer by vacuuming. The pressure is 200Pa, 3h Discharge, obtain double-terminal carboxyl lactic acid;

[0119] 1.2 Add 330g of terephthalic acid, 300g of adipic acid, 520g of butanediol, 10g of glycerin, 1g of tetrabutyl titanate and 200g of double-terminal carboxyl lactic acid obtained in Example 1.1 into the reaction kettle in sequence, and raise the temperature to 180°C And stir the reactant, collect the water generated by the reaction at the same time, when the reaction no longer distills out the liquid, raise the temperature to 250°C, vacuumize the polycondensation reaction, the pressure is 200Pa, and discharge the material for 5h to obtain polyhexamethylene terephthalate Butylene glycol lactic acid succinate random copolymer.

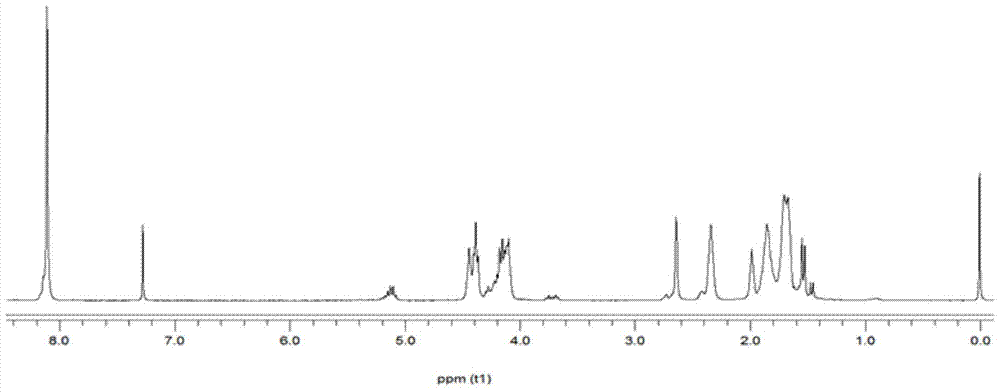

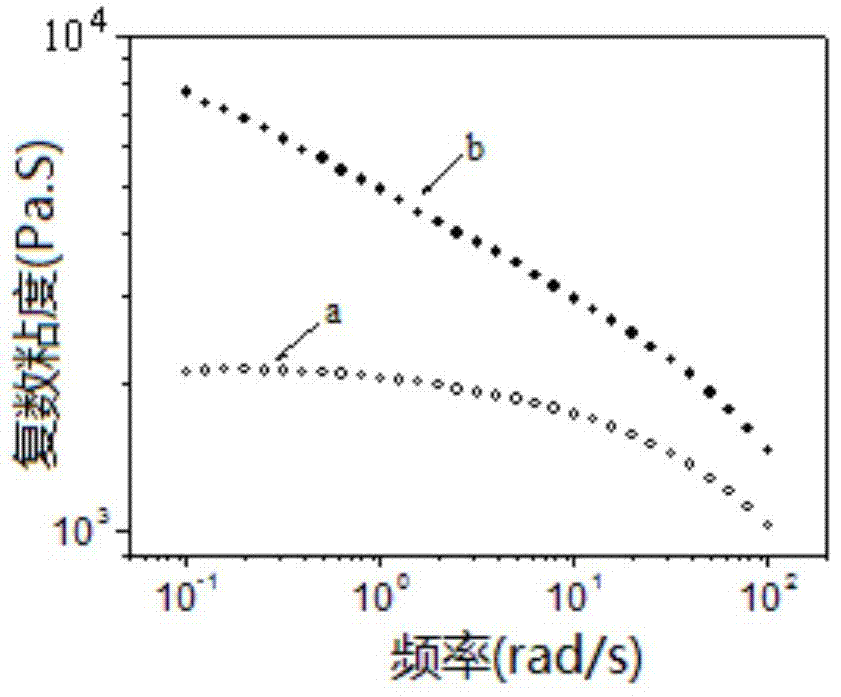

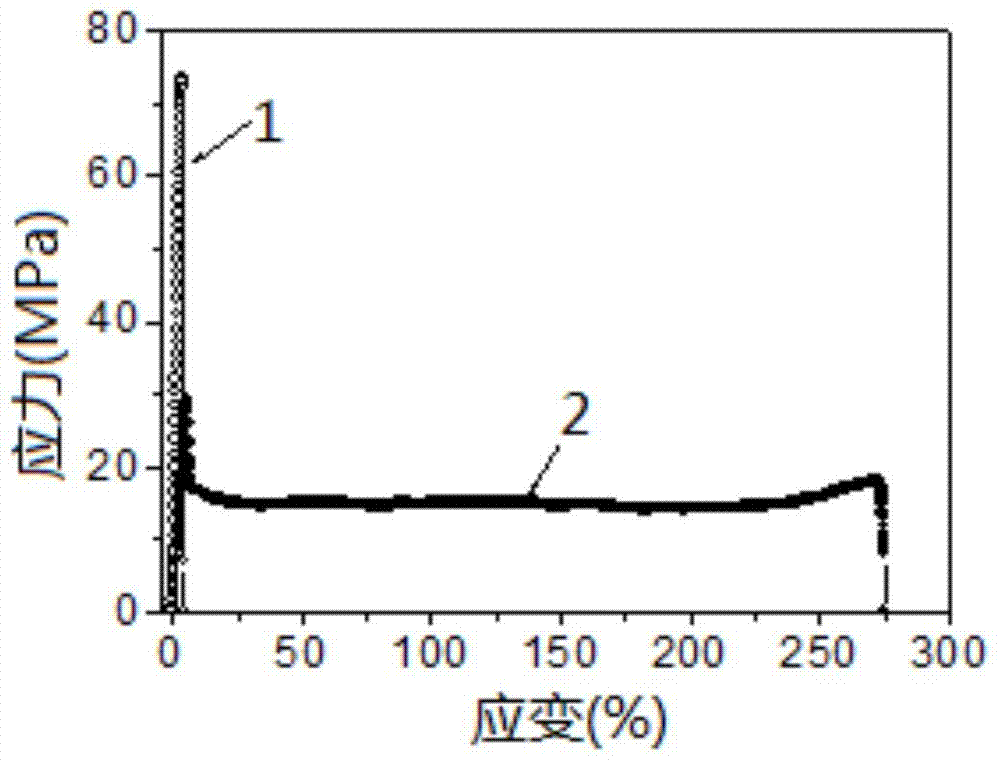

[0120] The present inve...

Embodiment 2

[0124] Add 380g of dimethyl terephthalate, 300g of adipic acid, 520g of butanediol, 1g of glycerin, 1g of tetrabutyl titanate and 100g of double-terminal carboxyl lactic acid obtained in Example 1.1 into the reaction kettle in sequence, and then heat up Stir the reactant to 150°C, and collect the water generated by the reaction at the same time. When the reaction no longer distills out liquid, raise the temperature to 270°C, vacuumize the polycondensation reaction, and the pressure is 500Pa, and the material is discharged for 4 hours to obtain polyterephthalene Butylene glycol formate adipate lactic acid succinate random copolymer.

[0125] The present invention carries out gel permeation chromatographic analysis on the obtained copolymer, and the relative number average molecular weight of the obtained polybutylene lactic adipate terephthalate random copolymer is 25.0 kg / mol.

[0126] The present invention tests the performance of the product according to the above-mentioned ...

Embodiment 3

[0128] After adding 300g of phthalic anhydride, 300g of adipic acid, 420g of butanediol, 1g of glycerol, 1g of tetrabutyl titanate and 100g of double-terminal carboxyl lactic acid obtained in Example 1.1 into the reactor, the temperature was raised to 150 ℃ and stir the reactant, and collect the water generated by the reaction at the same time. When no liquid distills out of the reaction, the temperature is raised to 250 ℃, and the vacuum polycondensation reaction is carried out. Butylene glycol lactic acid succinate random copolymer.

[0129] The present invention carries out gel permeation chromatographic analysis on the obtained copolymer, and the relative number average molecular weight of the obtained polybutylene phthalate adipate succinate random copolymer is 22.0 kg / mol.

[0130] The present invention tests the performance of the product according to the above-mentioned technical scheme, and the test results show that: the polybutylene terephthalate adipate succinate r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com