Preparation method of water reducing agent with hyper-branched topological structure and application of water reducing agent

A topology structure and water-reducing agent technology, applied in the field of building materials, can solve the problems of molecular structure damage of water-reducing agent, economical and environmental protection constraints, high production cost, and achieve small slump loss, low mortar viscosity, The effect of high water reduction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

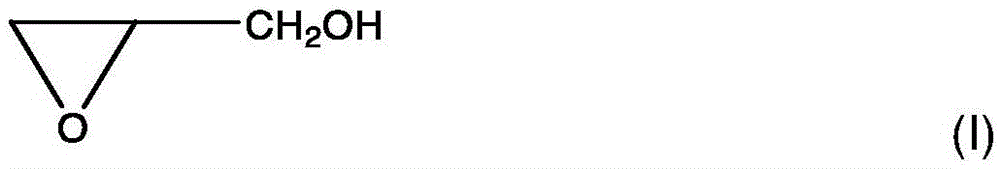

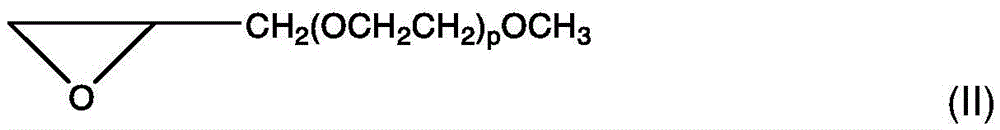

Method used

Image

Examples

Embodiment 1

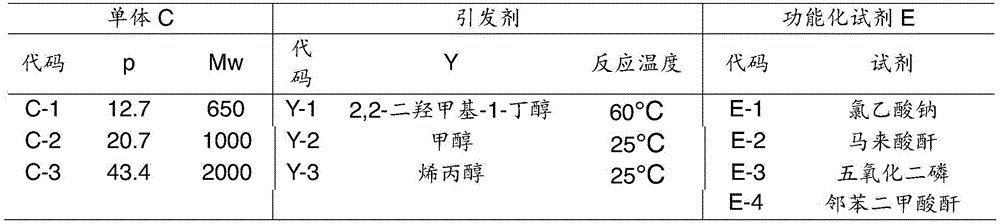

[0048] In this embodiment, the initiator is Y-1, the monomer C is C-1, the functional reagent E is E-1, and the auxiliary agent Z is sodium hydroxide. The molar ratio of each reactant is: Y-1:B:C-1:Z:E-1=1:70:20:100:110.

[0049] Take 1000g of monomer C-1 and mix it with 398g of monomer B evenly. Under the protection of nitrogen, put 11.58g of initiator Y-1 into the polyether reaction kettle at a constant speed of 58.3g / h at 90°C. After 24h, the addition is completed, and then react at the same temperature for 1h to obtain the intermediate Body D-1 (Mw=1.75×10 4 , conversion rate 96.1%). After cooling to room temperature, add 308g of sodium hydroxide and pretreat at 40°C for 0.5h, add 986g of functionalization reagent E-1, react at 60°C for 6h, and then wash with ethanol-water (2:1v / v) solution 3-5 times, add water to dissolve into a solution with a solid content >20%, and then adjust the pH to 8-9 with hydrochloric acid or liquid caustic soda to obtain a water reducer A-1 ...

Embodiment 2

[0051] In this embodiment, the initiator is Y-1, the monomer C is C-2, the functional reagent E is E-1, and the auxiliary agent Z is sodium hydroxide. The molar ratio of each reactant is: Y-1:B:C-2:Z:E-1=1:110:20:160:180.

[0052] Take 1000g of monomer C-2 and mix it with 407g of monomer B evenly. Under the protection of nitrogen, put 6.70g of initiator Y-1 into the polyether reaction kettle at a constant speed of 58.6g / h at 105°C. After 24h, the addition is completed, and then react at the same temperature for 1.5h to obtain Intermediate D-2 (Mw=2.55×10 4 , conversion rate 95.5%). After cooling to room temperature, add 320g of sodium hydroxide and pretreat at 50°C for 45min, add 1048g of functionalization reagent E-1, react at 75°C for 3h, and then wash with ethanol-water (2:1v / v) solution for 3 -5 times, add water to dissolve into a solution with a solid content>20%, and then adjust the pH to 8-9 with hydrochloric acid or liquid caustic soda to obtain the water reducer A-...

Embodiment 3

[0054] In this embodiment, the initiator is Y-1, the monomer C is C-3, the functional reagent E is E-1, and the auxiliary agent Z is sodium hydroxide. The molar ratio of each reactant is: Y-1:B:C-3:Z:E-1=1:150:20:250:300.

[0055] Take 1000g of monomer C-3 and mix it with 378g of monomer B evenly. Under the protection of nitrogen, put 6.70g of initiator Y-1 into the polyether reactor at a constant speed of 57.4g / h at 120°C. After 24h, the addition is completed, and then react at the same temperature for 2h to obtain the intermediate Body D-3 (Mw=3.65×10 4 , conversion rate 92.3%). After cooling to room temperature, add 250g of sodium hydroxide and pretreat at 60°C for 1h, add 874g of functionalization reagent E-1, react at 90°C for 3h, and then wash with ethanol-water (2:1v / v) solution for 3 -5 times, add water to dissolve into a solution with a solid content>20%, and then adjust the pH to 8-9 with hydrochloric acid or liquid caustic soda to obtain the water reducer A-3 (Mw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com