Si-TiO2-PANI (silicon-titanium dioxide-polyaniline) composite material assembled based on ternary hierarchy and application thereof

A composite material, titanium dioxide technology, applied in organic compound/hydride/coordination complex catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of low photoelectric conversion efficiency, easy agglomeration, and difficult recycling, etc. Achieve excellent anti-reflection performance, not easy to agglomerate, and easy to recycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

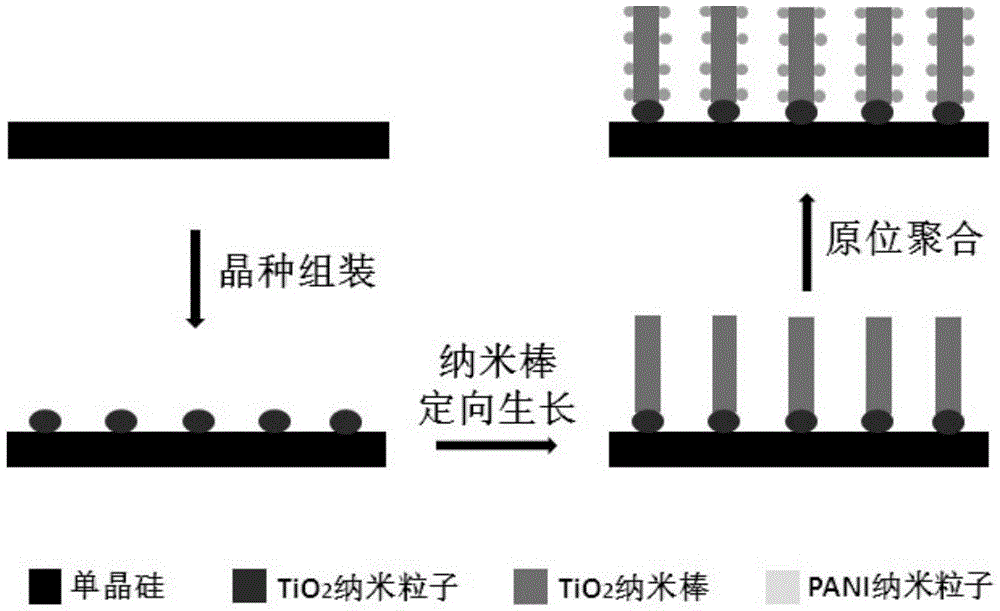

[0023] Step 1: Growth of TiO on the surface of single crystal silicon 2 seed crystal

[0024] Place the wafer in NH 3 h 2 O, H 2 o 2 and H 2 In the mixed solution of O, the volume ratio is 1:1:5, the temperature is 80°C, and the heating time is 30min. Then, immerse in the isopropanol solution of tetrabutyl titanate with a concentration of 0.075mol / L for pulling, the pulling speed is 2mm / s, and the pulling is repeated 20 times. Calcined in the furnace for about 30min.

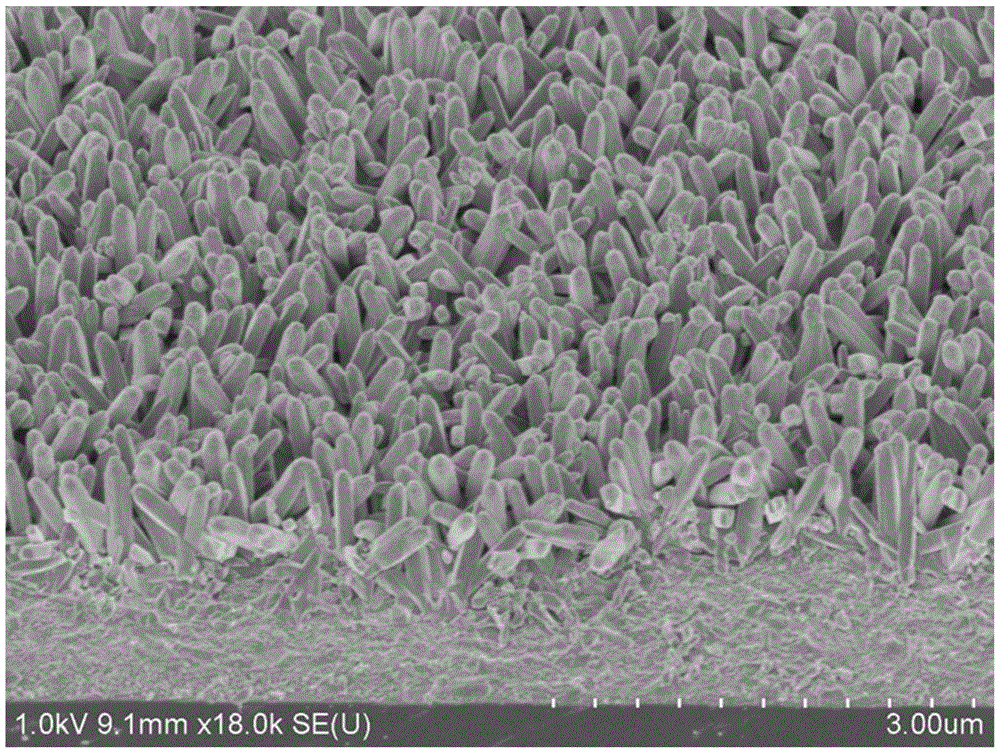

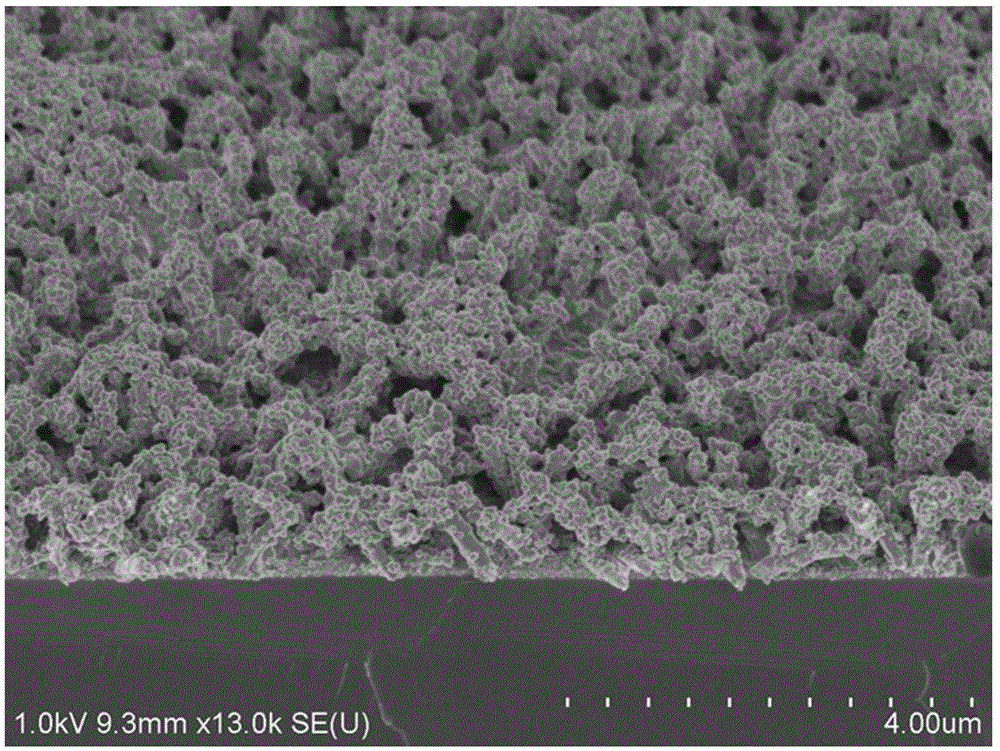

[0025] Step 2: TiO 2 Seed induced TiO 2 Preparation of nanorods

[0026] Attach TiO to the surface obtained in step 2 2 The seeded silicon wafers were placed under hydrothermal conditions to grow TiO 2 Nano stave. The hydrothermal synthesis condition is at a temperature of 130°C, and treated in a reactor filled with 10mL deionized water, 10mL concentrated hydrochloric acid (37% mass fraction) and 0.5mL tetrabutyl titanate for 8h, and then the sample was taken out and blown dry with nitrogen .

[00...

Embodiment 2

[0031] Step 1: Growth of TiO on the surface of single crystal silicon 2 seed crystal

[0032] Place the wafer in NH 3 h 2 O, H 2 o 2 and H 2 In the mixed solution of O, the volume ratio is 1:1:5, the temperature is 80°C, and the heating time is 40min. Then, immerse in the isopropanol solution of tetrabutyl titanate with a concentration of 0.05mol / L for pulling. The pulling speed is 2mm / s, and the pulling is repeated 15 times. Finally, the above sample is placed in a 450°C muffle Calcined in the furnace for about 1h.

[0033] Step 2: TiO 2 Seed induced TiO 2 Preparation of nanorods

[0034] The surface obtained in step 1 is attached with TiO 2 The seeded silicon wafers were placed under hydrothermal conditions to grow TiO 2 Nano stave. The hydrothermal synthesis condition is at a temperature of 130°C, and treated in a reactor filled with 10mL deionized water, 10mL concentrated hydrochloric acid (37% mass fraction) and 0.5mL tetrabutyl titanate for 8h, and then the s...

Embodiment 3

[0039] Step 1: Growth of TiO on the surface of single crystal silicon 2 seed crystal

[0040] Place the wafer in NH 3 h 2 O, H 2 o 2 and H 2 In the mixed solution of O, the volume ratio is 1:1:5, the temperature is 90°C, and the heating time is 30min. Then, immerse in the isopropanol solution of tetrabutyl titanate with a concentration of 0.1mol / L for pulling. The pulling speed is 2mm / s, and the pulling is repeated 10 times. Finally, the above sample is placed in a 500°C muffle Calcined in the furnace for about 30min.

[0041] Step 2: TiO 2 Seed induced TiO 2 Preparation of nanorods

[0042] The surface obtained in step 1 is attached with TiO 2 The seeded silicon wafers were placed under hydrothermal conditions to grow TiO 2 Nano stave. The hydrothermal synthesis condition is at a temperature of 120°C, and treated in a reactor filled with 10mL of deionized water, 10mL of concentrated hydrochloric acid (37% by mass) and 0.5mL of tetrabutyl titanate for 8h, and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Average height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com