Positive/negative (P/N) heterojunction based silicon/titanium dioxide three-dimensional composite material with synergic anti-reflection performance and application thereof

A composite material, titanium dioxide technology, applied in the direction of climate sustainability, sustainable manufacturing/processing, photovoltaic power generation, etc., can solve problems such as single reduction of light reflection, achieve excellent anti-reflection performance, reduce compounding, and simple preparation method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

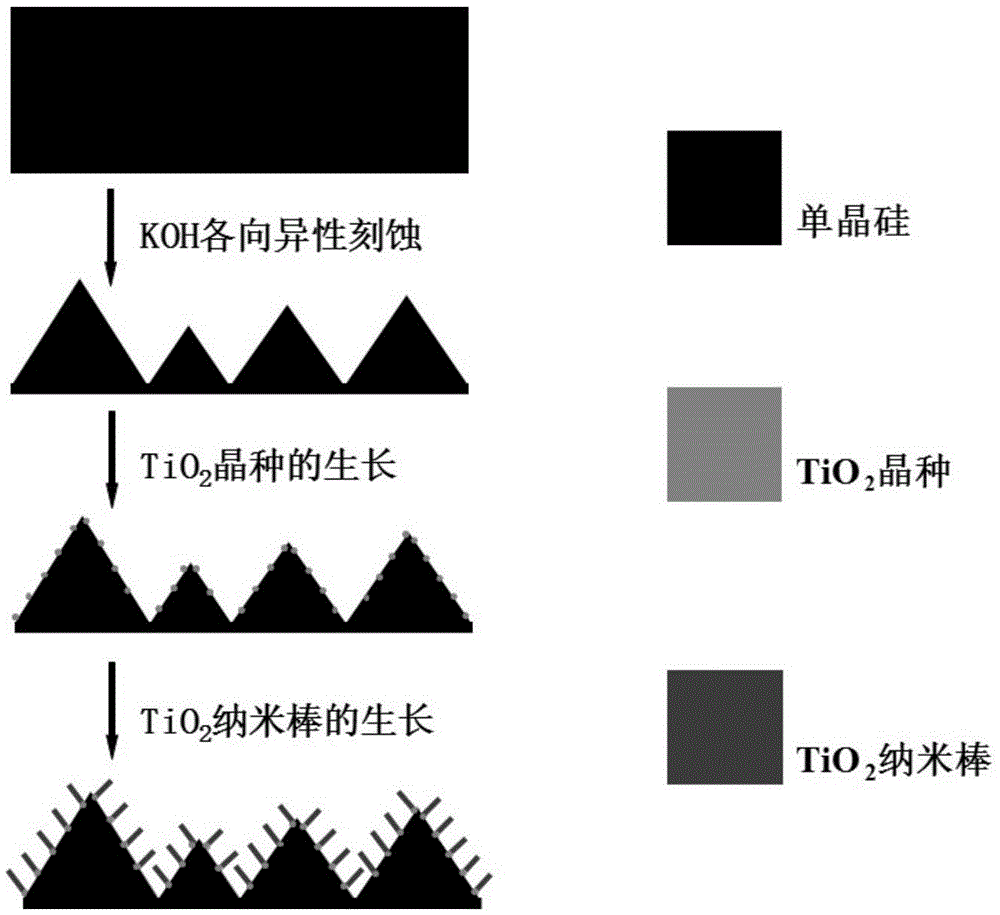

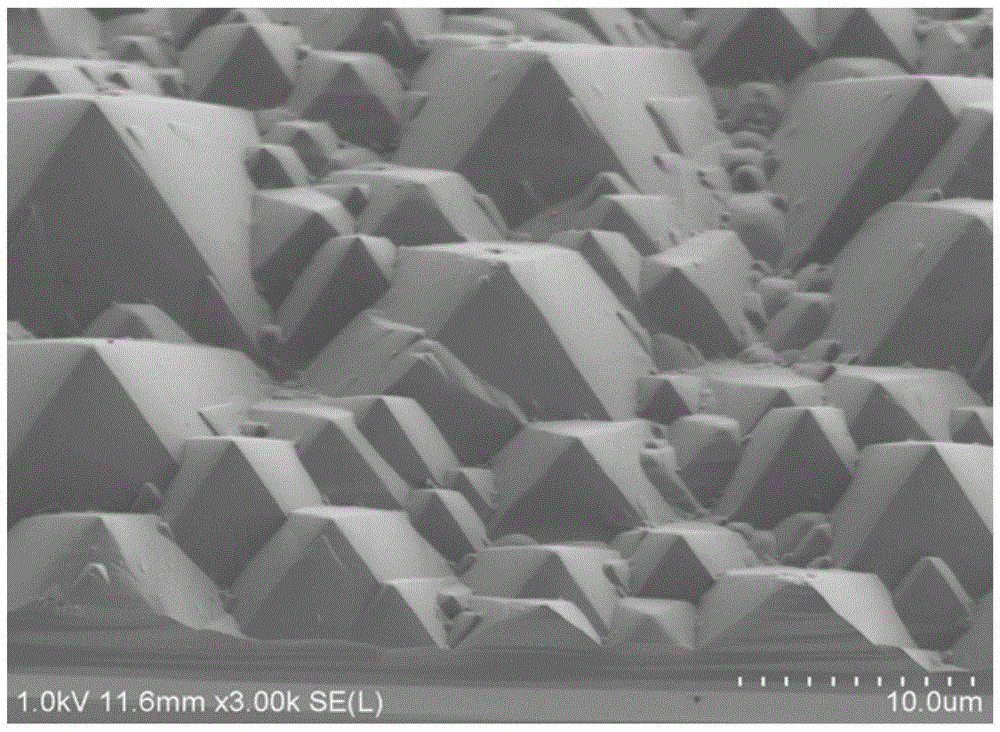

[0024] Step 1: Preparation of silicon cone

[0025] Prepare 100 mL of KOH solution with pH=13, add 25 mL of isopropanol to it, place the silicon wafer in the solution, etch at 70° C. for 30 min, and continuously stir with mechanical stirring during the etching process. After etching, the wafers were rinsed with distilled water and then blown dry with nitrogen.

[0026] Step 2: Growing TiO on the sidewall of the silicon cone 2 seed crystal

[0027] Place the silicon chip with silicon cone structure obtained in step 1 in NH 3 h 2 O, H 2 o 2 and H 2 In the mixed solution of O, the volume ratio is 1:1:5, the temperature is 80°C, and the heating time is 30min. Then, immerse in the isopropanol solution of tetrabutyl titanate with a concentration of 0.075mol / L for pulling, the pulling speed is 2mm / s, and the pulling is repeated 20 times. Calcined in the furnace for about 30min.

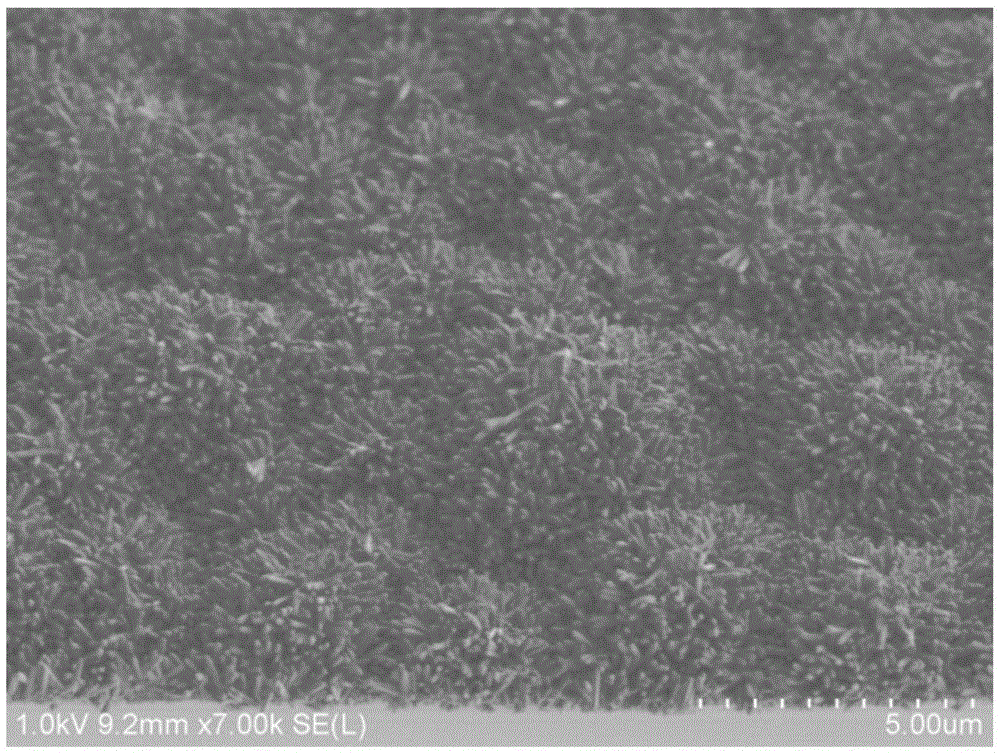

[0028] Step 3: 3D Si / TiO 2 Composite material preparation

[0029] Attach TiO to the surface o...

Embodiment 2

[0032] Step 1: Preparation of silicon cone

[0033] Prepare 100 mL of KOH solution with pH=14, add 25 mL of isopropanol to it, place the silicon wafer in the solution, etch at 80° C. for 45 min, and continuously stir with magnetic stirring during the etching process. After etching, the wafers were rinsed with distilled water and then blown dry with nitrogen.

[0034] Step 2: Growing TiO on the sidewall of the silicon cone 2 seed crystal

[0035]Place the silicon chip with silicon cone structure obtained in step 1 in NH 3 h 2 O, H 2 o 2 and H 2 In the mixed solution of O, the volume ratio is 1:1:5, the temperature is 80°C, and the heating time is 40min. Then, immerse in the isopropanol solution of tetrabutyl titanate with a concentration of 0.05mol / L for pulling. The pulling speed is 2mm / s, and the pulling is repeated 15 times. Finally, the above sample is placed in a 450°C muffle Calcined in the furnace for about 1h.

[0036] Step 3: 3D Si / TiO 2 Composite material pr...

Embodiment 3

[0040] Step 1: Preparation of silicon cone

[0041] Prepare 100 mL of KOH solution with pH=14, add 25 mL of isopropanol to it, place the silicon wafer in the solution, etch at 90° C. for 60 min, and continuously stir with mechanical stirring during the etching process. After etching, the wafers were rinsed with distilled water and then blown dry with nitrogen.

[0042] Step 2: Growing TiO on the sidewall of the silicon cone 2 seed crystal

[0043] Place the silicon chip with silicon cone structure obtained in step 1 in NH 3 h 2 O, H 2 o 2 and H 2 In the mixed solution of O, the volume ratio is 1:1:5, the temperature is 90°C, and the heating time is 30min. Then, immerse in the isopropanol solution of tetrabutyl titanate with a concentration of 0.1mol / L for pulling. The pulling speed is 2mm / s, and the pulling is repeated 10 times. Finally, the above sample is placed in a 500°C muffle Calcined in the furnace for about 30min.

[0044] Step 3: 3D Si / TiO 2 Composite materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com