Adhesive used for biomass solid fuel

A solid fuel and biomass technology, applied in the field of adhesives, can solve problems such as poor lubricity, rising production costs, and weak adhesion, and achieve the effects of improving processing performance, increasing productivity, and high wetting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

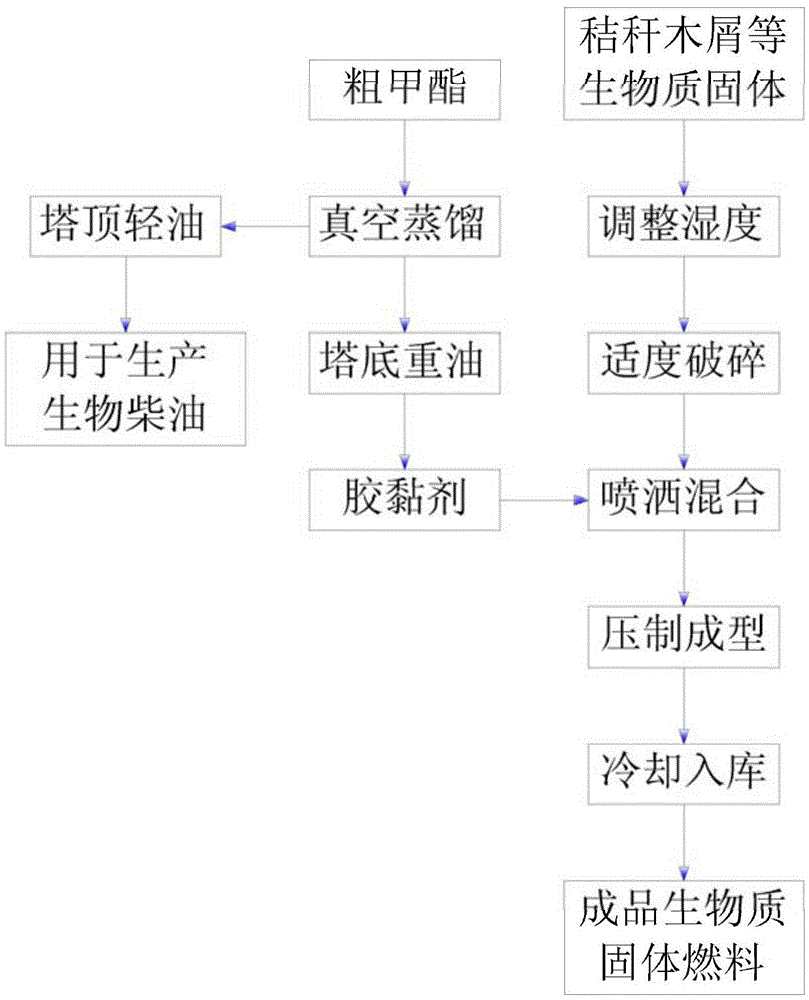

[0023] see figure 1 , the adhesive in the biomass solid fuel processing technology is the heavy bottom oil obtained from the biodiesel production process. The heavy oil at the bottom of the tower is the heavy oil at the bottom of the tower obtained through vacuum distillation of fatty acid methyl esters in the biodiesel production process. It shall not contain crude glycerin, waste methanol, gutter oil, acidified oil, light oil, petrochemical residue and other components that are not pure substances. The heavy oil at the bottom of the tower includes triglycerides, diglycerides, monoglycerides with large molecular weight and high boiling point, polymers of a small amount of oil, and oil-soluble impurities. The heavy oil at the bottom of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com