Euphausia superba oil extraction method

An Antarctic krill oil and extraction method technology, applied in the field of extracting shrimp oil, to reduce energy consumption, increase return on investment, and avoid pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

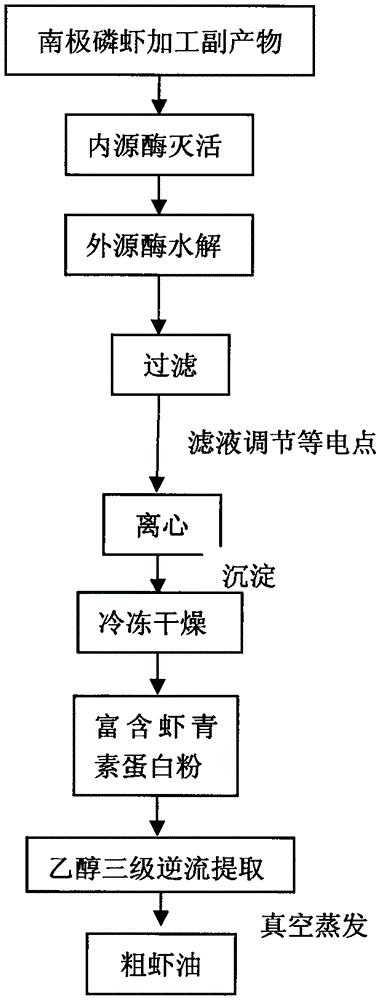

[0025] (1) The Antarctic krill is harvested four times, and the obtained processing by-products are used as raw materials.

[0026] (2) Cook the raw materials at 100°C for 10min, add distilled water (mass ratio = 1:4), adjust the temperature to 50°C, keep it for 10min, adjust the pH to 8.5, add alkaline protease 3000U / g protein, and enzymatically hydrolyze for 2h Finally, after boiling for 10min to kill the enzyme, after cooling, after filtering with 80 mesh spun gauze, the filtrate was collected.

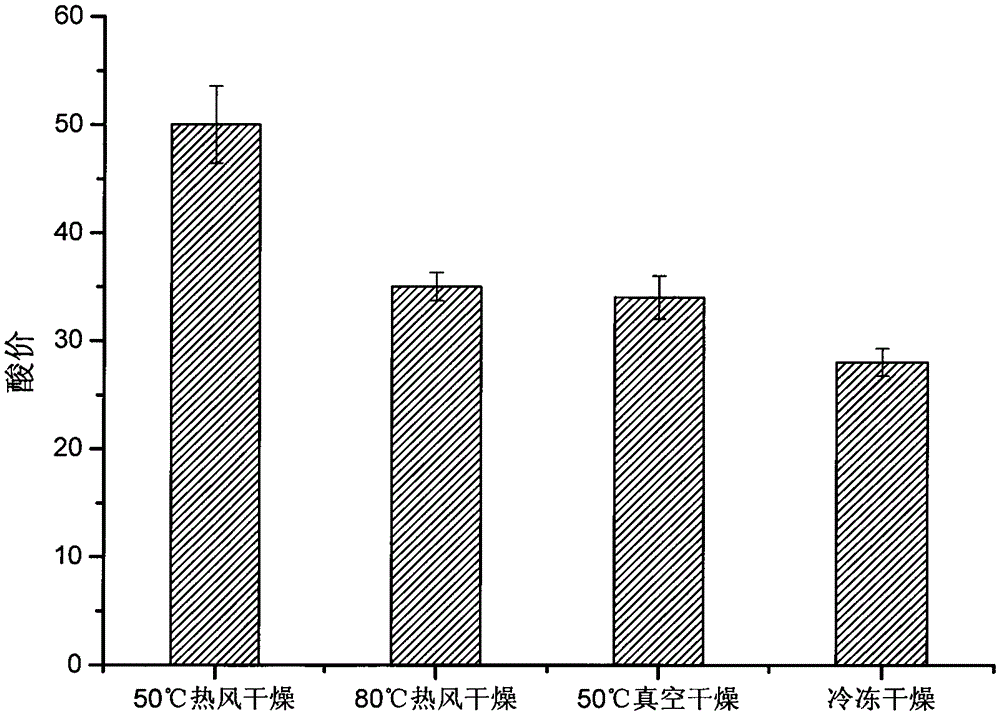

[0027] (3) After adjusting the filtrate obtained in the above steps to pH 4.5, let it stand for 30 minutes, and centrifuge at 8000 r / min to obtain a paste-like precipitate, which is subjected to freeze-drying treatment.

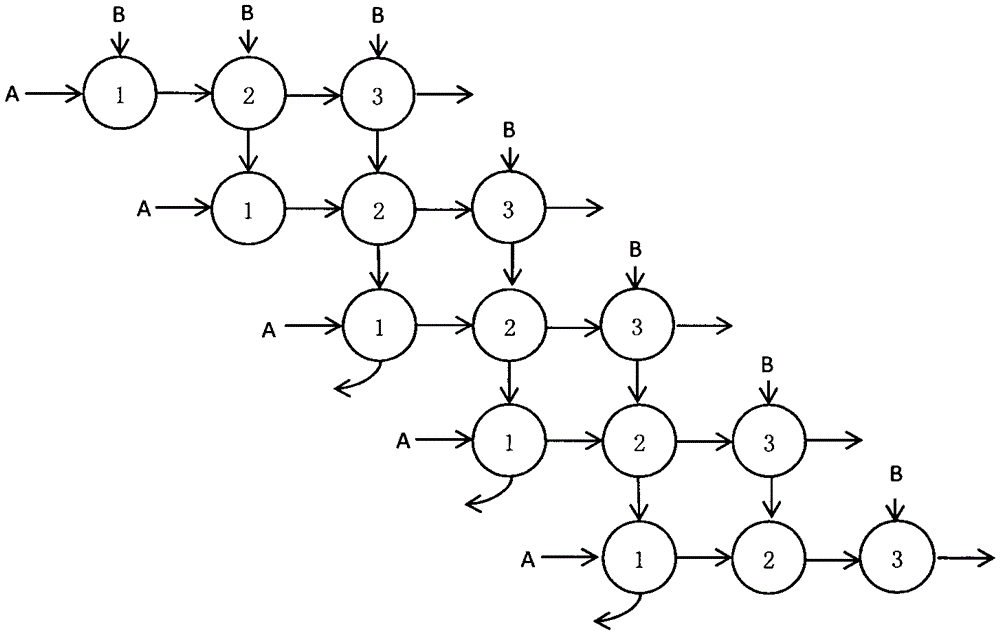

[0028] (4) Take ethanol as extraction solvent, adopt the method for extracting the shrimp oil in freeze-dried lipoprotein continuously by multistage countercurrent extraction, the number of extraction stages is 3 stages, and the solid-liquid ratio (w / v) of each st...

Embodiment 2

[0030] (1) The Antarctic krill is harvested four times, and the obtained processing by-products are used as raw materials.

[0031] (2) Cook the raw materials at 100°C for 10min, add distilled water (mass ratio = 1:4), adjust the temperature to 30°C, keep it for 10min, adjust the pH to 8.5, add alkaline protease 2000U / g protein, and enzymatically hydrolyze After 1 hour, boil for 10 minutes to inactivate the enzyme, after cooling, filter with 80-mesh spun gauze, and collect the filtrate.

[0032] (3) After adjusting the filtrate obtained in the above steps to pH 4.5, let it stand for 30 minutes, and centrifuge at 8000 r / min to obtain a paste-like precipitate, which is subjected to freeze-drying treatment.

[0033] (4) Take ethanol as extraction solvent, adopt the method for extracting the shrimp oil in freeze-dried lipoprotein continuously by multistage countercurrent extraction, the number of extraction stages is 3 stages, and the solid-liquid ratio (w / v) of each stage extract...

Embodiment 3

[0035] (1) The Antarctic krill is harvested four times, and the obtained processing by-products are used as raw materials.

[0036] (2) Cook the raw material at 100°C for 10min, add distilled water (mass ratio = 1:4), adjust the temperature to 60°C, keep it for 10min, adjust the pH to 8.5, add alkaline protease 5000U / g protein, and enzymolyze After 3 hours, boil for 10 minutes to inactivate the enzyme, after cooling, filter with 80 mesh silk gauze, and collect the filtrate.

[0037] (3) After adjusting the filtrate obtained in the above steps to pH 4.5, let it stand for 30 minutes, and centrifuge at 8000 r / min to obtain a paste-like precipitate, which is subjected to freeze-drying treatment.

[0038] (4) Take ethanol as extraction solvent, adopt the method for extracting the shrimp oil in freeze-dried lipoprotein continuously by multistage countercurrent extraction, the number of extraction stages is 3 stages, and the solid-liquid ratio (w / v) of each stage extraction is 1: 9. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com