Corrosion inhibitor for aluminum corrosion control

A technology for corrosion control and corrosion inhibitor, applied in the field of corrosion inhibitor, can solve the problems of poor operation of the foundry process, intrusion of seawater, and reduced casting efficiency, and achieve the problem of solving the problem of drainage outlet, saving water resources, and ensuring the appearance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in further detail below by embodiment, but protection scope of the present invention is not limited to described content, the reagent used in the embodiment, if no special instruction is the reagent of routine commercially available reagent or by conventional method preparation, method Unless otherwise specified, all are conventional methods.

[0017] According to the specific formula given in the examples, after dissolving benzotriazole with isopropanol, put 2-phosphonobutane-1,2,4 tricarboxylic acid, aminotrimethylene phosphonic acid, Zinc sulfate heptahydrate, after each medicament is put, should be fully stirred to ensure the dissolution of the medicament, and finally add water for compounding to obtain the corrosion inhibitor for aluminum corrosion control of the present invention.

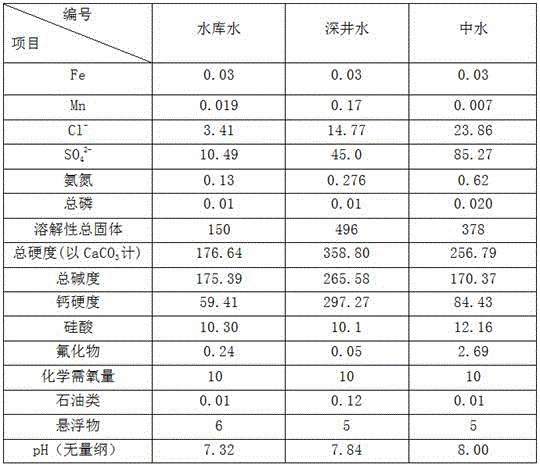

[0018] Below through the experiment of three stages in the reclaimed water treatment station of aluminum factory, comprise: the effect of small test ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com