Water-cooled-wall multi-stage stair type incinerator

A stepped, water-cooled wall technology, applied in the field of incinerators, can solve the problems of destroying the fluidized state, good air tightness, high investment cost, and achieve the effect of strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

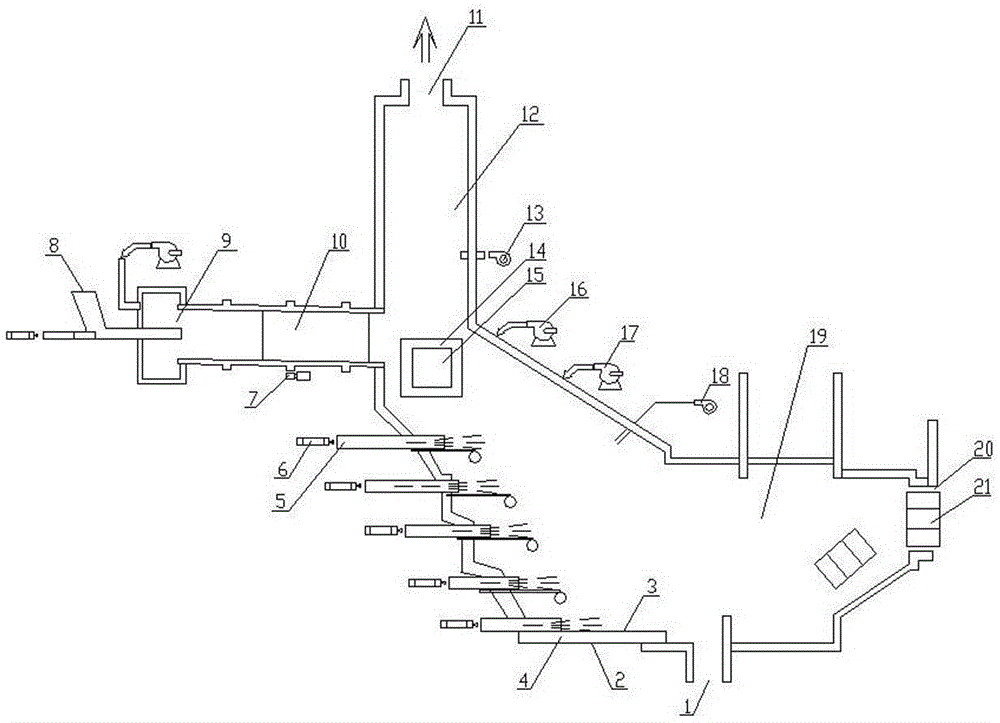

[0016] Such as figure 1 As shown, the water-cooled wall multi-stage stepped incinerator of the present invention includes a furnace body, the furnace body includes an inner wall 3 and an outer wall 2, and a gap 4 is left between the inner wall 3 and the outer wall 2 for cooling water circulation. There are flue gas outlets 11 and slag outlets 1 on the upper and bottom parts of the furnace body respectively, and there is a feeding port 9 on the furnace wall on the side in the middle of the height direction of the furnace body. Combustion chamber 19, that section of furnace body above feed port 9 constitutes secondary combustion chamber 12. A rotary kiln feed device 10 and a feed device 8 are sequentially connected to the feed port 9 . The part of the furnace body where the primary combustion chamber 19 is located is arranged in an inclined shape, and its lower side furnace wall is processed into a multi-stage step shape, and a stirring device is provided on the horizontal dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com