Method for rapidly detecting activity of nitrilase

A nitrilase and activity technology, applied in the field of biochemical analysis, can solve problems such as low sensitivity and low throughput, and achieve the effects of simple operation process, simple equipment and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

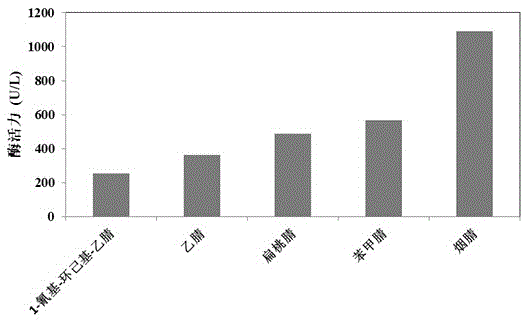

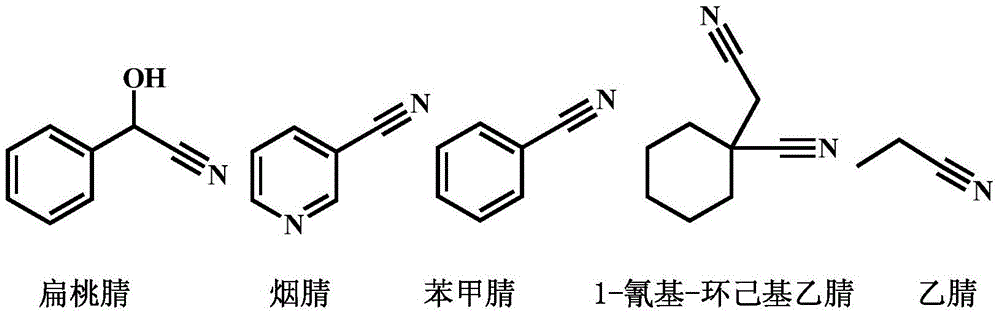

[0023] Embodiment 1 nitrilase reaction process and sample processing

[0024] Resuspend 50 mg of Escherichia coli resting cells containing the nitrilase gene in 5 mL of 0.1M phosphate buffer solution, add an appropriate amount of 1-cyano-cyclohexyl acetonitrile (final concentration 50 mM), and place in a 30°C, 180r / min Shaker reaction 8h. Terminate the reaction with methanol, centrifuge at 4°C to obtain a supernatant, and then dilute it 5 times with double distilled water, which is the sample of nitrile compounds hydrolyzed by nitrilase.

Embodiment 2

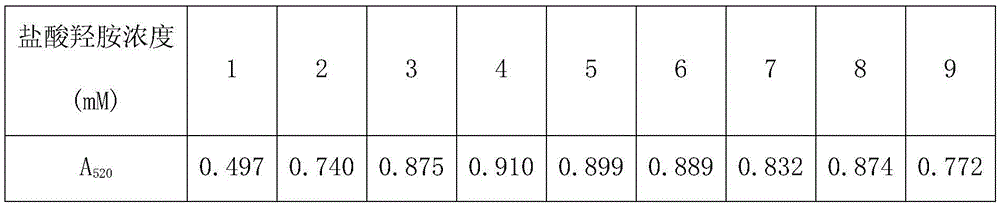

[0025] Embodiment 2 hydroxylamine hydrochloride concentration optimization

[0026] Take 1ml of the 5-fold diluted 1-cyano-cyclohexylacetonitrile sample hydrolyzed by nitrilase into a 5ml EP tube, first add 3mL of ethanol solution of hydroxylamine hydrochloride, the concentrations are 1mM, 2mM, 3mM, 4mM, 5mM, 6mM, 7mM, 8mM and 9mM, followed by adding 0.2mL of DCC ethanol solution, the concentration is 0.2M. The mixture was shaken and mixed, heated in a water bath, and heated at 30°C for 20min. After the water bath is completed, add 0.05ml of ferric chloride solution in ethanol, the concentration of which is 0.8M. After developing the color for 10 minutes, measure the absorbance value at 520nm with an ultraviolet spectrophotometer. The results are shown in Table 1. When the added amount increased from 1mM to 4mM, the absorbance increased continuously, and continued to increase the amount to 9mM, and the absorbance decreased continuously. Therefore, its optimum dosage is 4mM. ...

Embodiment 3 3

[0029] Embodiment 3 ferric chloride concentration optimization

[0030] Take 1ml of the 1-cyano-cyclohexylacetonitrile sample diluted 5 times into a 5ml EP tube, first add 3ml of ethanol solution of hydroxylamine hydrochloride, the concentration is 4mM, and then add 0.2ml of ethanol solution of DCC , and its concentration is 0.20M. The mixture was shaken and mixed, heated in a water bath, and heated at 30°C for 20min. After the water bath is completed, add 0.05ml of ferric chloride solution in ethanol, the concentration of which is 0.10M, 0.20M, 0.30M, 0.40M, 0.50M, 0.60M, 0.70M, 0.80M, 0.90M and 1.0MmM, After 10 min of color development, the absorbance value at 520 nm was measured with a UV spectrophotometer. The results show that when the content of ferric chloride increases from 0.1M to 0.5M, the corresponding absorption value increases continuously, but when the concentration of ferric chloride continues to increase to 1.0M, the corresponding absorption value basically t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com