Lithium metal oxide composite positive electrode material with multilayer structure, precursor material for constituting same, and preparation method and application for precursor material

A lithium metal oxide and composite positive electrode material technology, applied in structural parts, battery electrodes, electrochemical generators, etc., to achieve the effect of shortening the Li+ transmission path and improving the rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

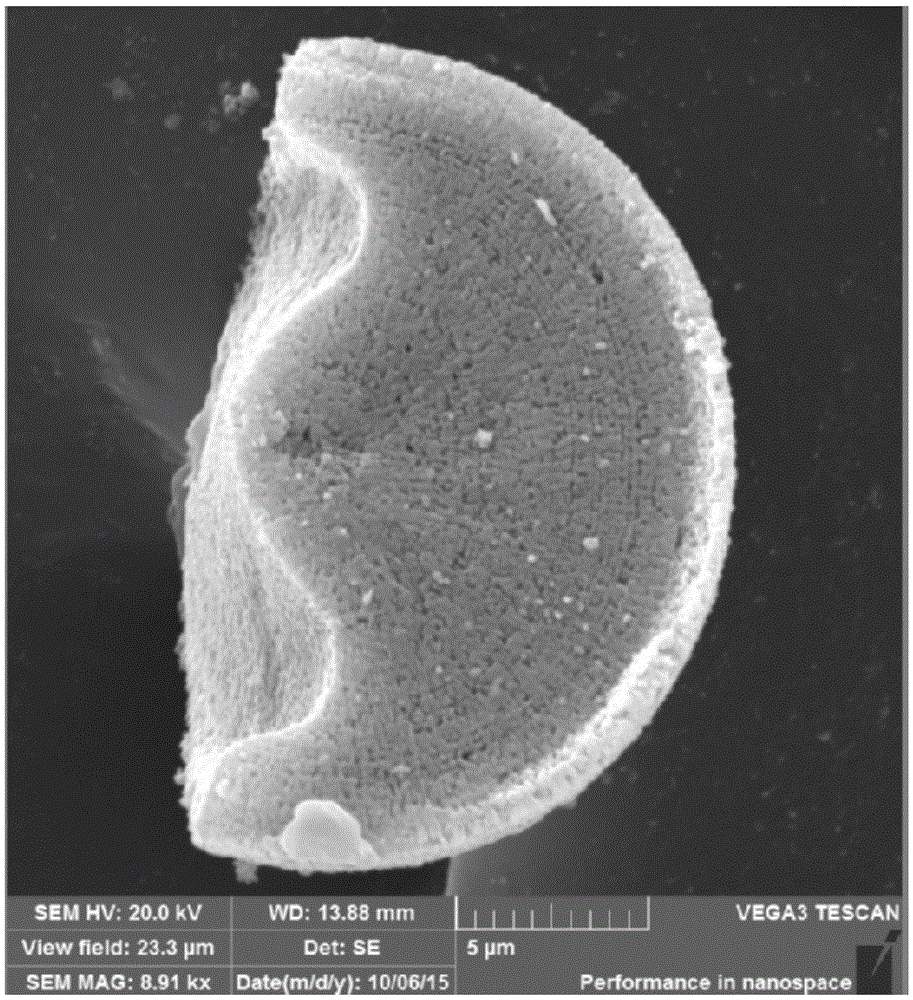

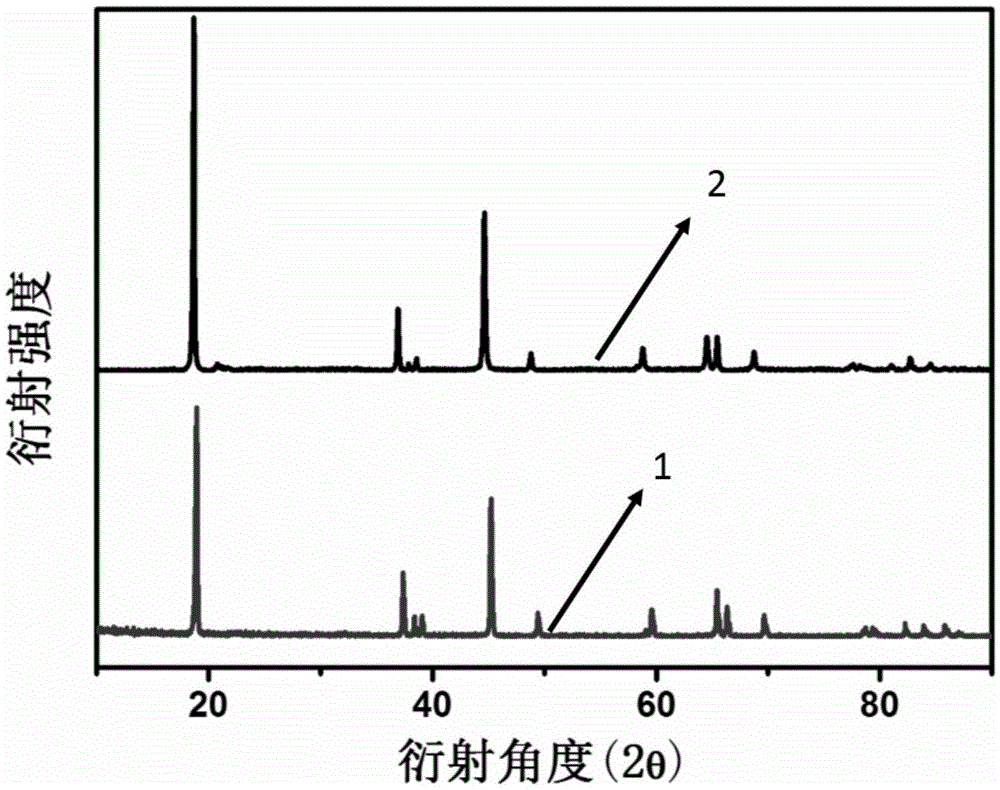

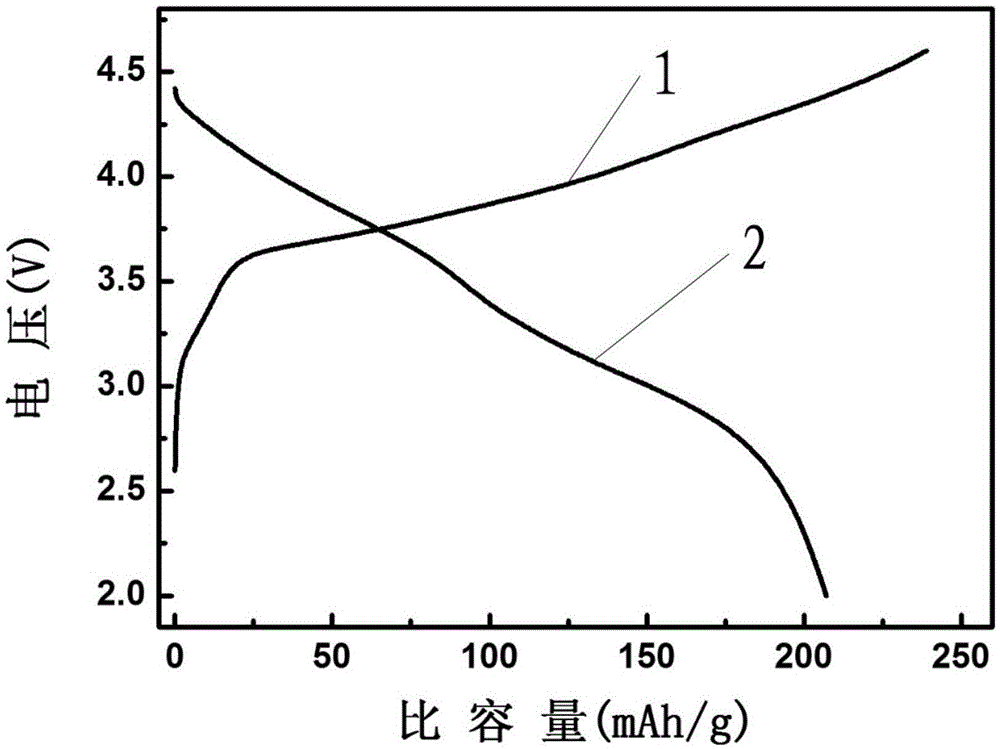

[0040]Specific Embodiment 1: The precursor material of the lithium metal oxide composite positive electrode material with a multi-layer structure in this embodiment, the precursor material is composed of metal hydroxides or metal carbonates of different components along the spherical shape layer by layer The stacked structure is composed of at least three layers: inner layer, middle layer and outer layer. The number of layers can be realized by changing the number of middle layers by controlling the reaction time;

[0041] The specific structure is: the diameter of the inner layer is less than 8 μm, and the chemical composition is uniform; the middle layer is formed by growing and stacking layers of metal hydroxides or metal carbonates of different components around the inner layer, and the thickness of the middle layer is between 0.1 μm and 30 μm. Among them, the thickness of the single layer is between 100nm-300nm, and the outer layer is mainly precipitated by the unreacted m...

specific Embodiment approach 2

[0042] Specific embodiment two: the preparation method of the precursor material of the lithium metal oxide positive electrode composite material with a multilayer structure in this embodiment, the precursor material is prepared according to the following steps:

[0043] 1. Prepare the solution: prepare the precipitant aqueous solution b1 with a concentration of 0.2mol / L~4mol / L and the complexing agent aqueous solution c1 with a concentration of 0.2mol / L~4mol / L; dissolve the nickel salt in water to make a concentration of 0.1mol / L~10mol / L nickel salt solution, dissolve cobalt salt in water to make cobalt salt solution with a concentration of 0.1mol / L~10mol / L, dissolve manganese salt in water to make a concentration of 0.1mol / L ~10mol / L manganese salt solution, dissolving M salt in water to make M salt solution with a concentration of 0.1mol / L~10mol / L, and then preparing the inner layer metal salt solution and the middle layer metal salt solution, the inner layer The layer meta...

specific Embodiment approach 3

[0050] Specific Embodiment 3: The difference between this embodiment and specific embodiment 2 is that in step 4, the composition of the metal salt solution in the middle layer is replaced every cycle, and multiple layers of different lithium metal oxide cathode material precursors are prepared in the middle layer. The metal hydroxide or metal carbonate formed; other steps and parameters are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com