CdS/BiVO4 compound semiconductor photocatalyst and preparation and application thereof

A compound semiconductor and photocatalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of photocorrosion, reduce the utilization rate of photogenerated holes, etc., and achieve simple raw materials and easy operation. , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

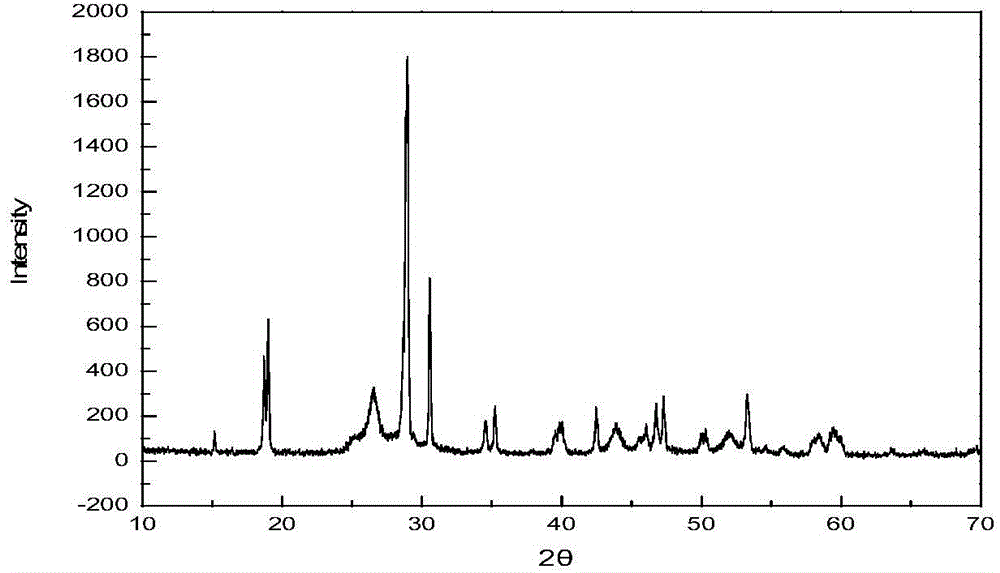

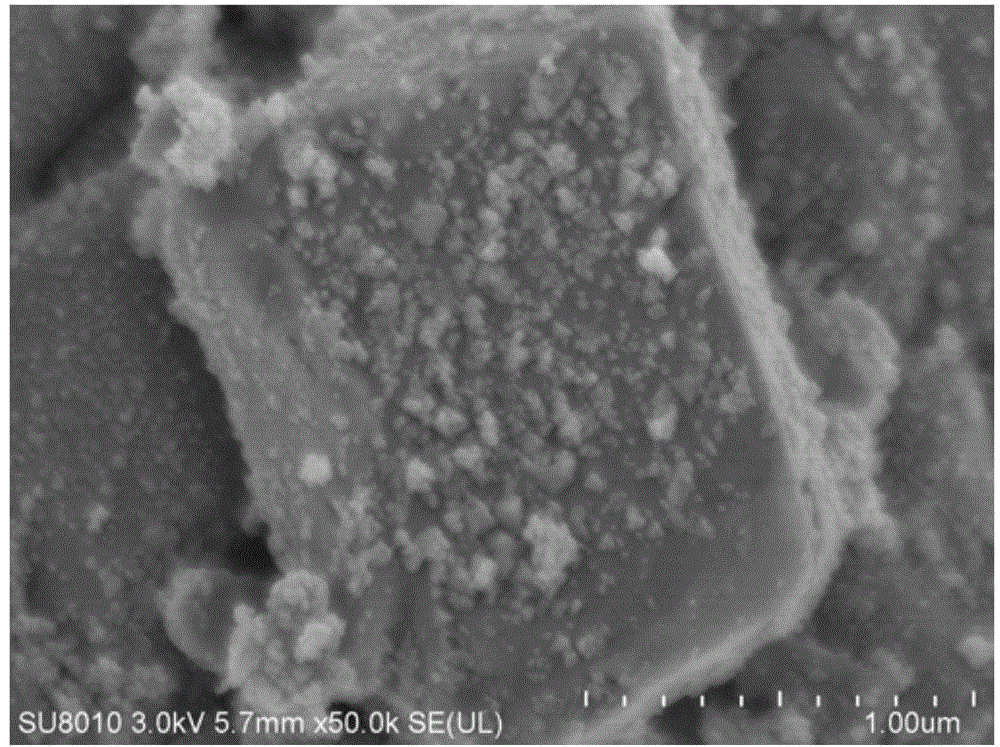

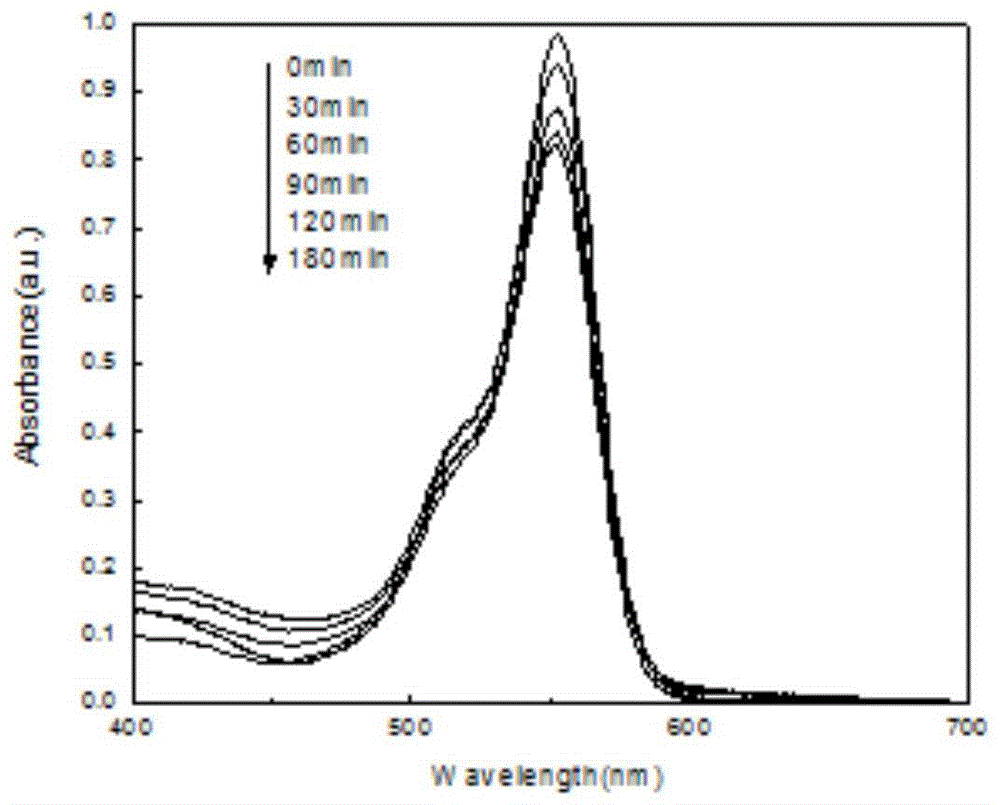

[0024] CdS / BiVO of the present invention 4 A compound semiconductor whose nominal composition is xCdS / (1-x)BiVO 4 , where x=0.5, (x represents the molar percentage of CdS in the system), and its specific preparation steps are as follows:

[0025] a) Weigh 1.4552gBi(NO 3 ) 3 ·5H 2 O dissolved in 4mol / L dilute HNO 3 In, weigh 0.351gNH 4 VO 3 Dissolve in 2mol / L NaOH solution, place on a magnetic stirrer and stir for 30 minutes to obtain solutions A and B; slowly drop B solution into A solution under constant stirring, continue stirring for 30 minutes, and then mix the solution Transfer to a high-pressure reactor, add deionized water to 80% of the volume of the reaction lining, adjust the pH to 5; heat to 160 ° C, keep warm for 9 hours; take out and cool naturally, centrifuge the obtained solution, and use deionized water and absolute ethanol Wash 2-3 times and dry at 80°C to get BiVO 4 .

[0026] b) Weigh 0.183gCdCl 2 and 0.264gNa 2 S·9H 2 O was dissolved in 30ml deio...

Embodiment 2

[0029] CdS / BiVO of the present invention 4 A compound semiconductor whose nominal composition is xCdS / (1-x)BiVO 4 , where x=0.5, (x represents the molar percentage of CdS in the system), and its specific preparation steps are as follows:

[0030] a) Weigh 1.4552gBi(NO 3 ) 3 ·5H 2 O dissolved in 3mol / L dilute HNO 3 In, weigh 0.351gNH 4 VO 3Dissolve in 3mol / L NaOH solution, place on a magnetic stirrer and stir for 30 minutes to obtain solutions A and B; slowly drop B solution into A solution under constant stirring, continue stirring for 30 minutes, and then mix the solution Transfer to a high-pressure reactor, add deionized water to 80% of the volume of the reaction lining, adjust the pH to 5; heat to 180 ° C, keep warm for 12 hours; take out and cool naturally, centrifuge the obtained solution, and use deionized water and absolute ethanol Wash 2-3 times and dry at 80°C to get BiVO 4 .

[0031] b) Weigh 0.183gCdCl 2 and 0.264gNa 2 S·9H 2 O was dissolved in 30ml deio...

Embodiment 3

[0033] CdS / BiVO of the present invention 4 A compound semiconductor whose nominal composition is xCdS / (1-x)BiVO 4 , where x=0.4, (x represents the molar percentage of CdS in the system), and its specific preparation steps are as follows:

[0034] a) Weigh 1.4552gBi(NO 3 ) 3 ·5H 2 O dissolved in 2mol / L dilute HNO 3 In, weigh 0.351gNH 4 VO 3 Dissolve in 4mol / L NaOH solution, place on a magnetic stirrer and stir for 30 minutes to obtain solutions A and B; slowly drop B solution into A solution under constant stirring, continue stirring for 30 minutes, and then mix the solution Transfer to a high-pressure reactor, add deionized water to 80% of the volume of the reaction lining, adjust the pH to 5; heat to 160 ° C, keep warm for 9 hours; take out and cool naturally, centrifuge the obtained solution, and use deionized water and absolute ethanol Wash 2-3 times and dry at 80°C to get BiVO 4 .

[0035] b) Weigh 0.183gCdCl 2 and 0.264gNa 2 S·9H 2 O was dissolved in 30ml deio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com