Method for improving crude oil recovery ratio in dolomite reservoir by using microbial flora

A technology of microbial flora and recovery factor, applied in chemical instruments and methods, drilling composition and other directions, can solve problems such as few reports in literature, reduce crude oil viscosity and oil-water interfacial tension, simple operation and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

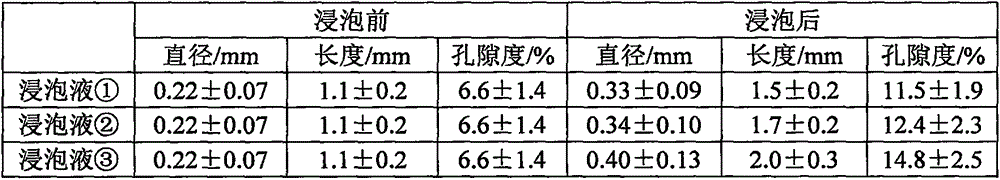

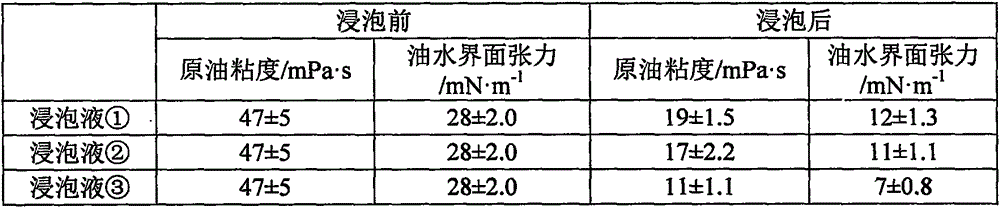

Embodiment 1

[0023] Weigh Pseudomonas aeruginosa, Bacillus cereus, Bacillus subtilis, Microbacterium, Escherichia coli, Pseudomonas putida, Bacillus licheniformis by weight ratio 5: 2: 1: 0.5: 0.5: 0.3: 0.3, Mix well, first inoculate in the culture tank with 2% weight-volume ratio, expand the culture for 12 hours, culture tank rotation speed 150rpm, culture temperature 32°C, control oxygen content 0.1mmol / L during the culture process; then use 5% weight-volume ratio Inoculate in a fermenter, ferment for 24 hours, rotate at a speed of 30 rpm, ferment at a temperature of 32° C., and control the oxygen content to 0.1 mmol / L during the fermenting process to obtain a fermented liquid of the microbial flora. The medium for expanding culture was 5g / L sucrose, 1g / L beef extract, 1g / L peptone, (NH 4 ) 2 SO 4 0.5g / L, MgSO 4 0.3g / L, K 2 HPO 4 0.2g / L, KH 2 PO 4 0.1g / L, CaCl 2 0.1g / L, the balance is water; the fermentation medium is 10g / L sucrose, 5g / L glucose, 3g / L beef extract, 3g / L peptone, ...

Embodiment 2

[0025] Weigh Pseudomonas aeruginosa, Bacillus cereus, Bacillus subtilis, Microbacterium, Escherichia coli, Pseudomonas putida, Bacillus licheniformis by weight ratio 15:10:10:8:5:1:1, Mix well, first inoculate in the culture tank with 4% weight-volume ratio, expand the culture for 24 hours, culture tank rotation speed 200rpm, culture temperature 32°C, control oxygen content 0.5mmol / L during the culture process; then inoculate with 8% weight-volume ratio Inoculated in a fermenter, fermented and cultivated for 48 hours, the rotating speed of the fermenter was 80 rpm, the fermentation temperature was 32° C., and the oxygen content was controlled at 0.5 mmol / L during the fermentation process to obtain the fermentation broth of the microbial flora. The culture medium of expansion is 10g / L of sucrose, 3g / L of beef extract, 3g / L of peptone, (NH 4 ) 2 SO 4 0.8g / L, MgSO 4 0.5g / L, K 2 HPO 4 0.4g / L, KH 2 PO 4 0.3g / L, CaCl 2 0.2g / L, the balance is water; the fermentation medium is...

Embodiment 3

[0027] Weigh Pseudomonas aeruginosa, Bacillus cereus, Bacillus subtilis, Microbacterium, Escherichia coli, Pseudomonas putida, Bacillus licheniformis by weight ratio 8:4:3:2:1:0.5:0.5, Mix well, first inoculate in the culture tank with 3% weight-volume ratio, expand the culture for 16 hours, culture tank rotation speed 180rpm, culture temperature 32°C, control oxygen content 0.2mmol / L during the culture process, then inoculate with 6% weight-volume ratio In a fermenter, ferment and cultivate for 36 hours, the rotation speed of the fermenter is 50 rpm, the fermentation temperature is 32° C., and the oxygen content is controlled at 0.2 mmol / L during the fermentation process to obtain the fermentation broth of the microbial flora. The expansion medium was 8g / L sucrose, 2g / L beef extract, 2g / L peptone, (NH 4 ) 2 SO 4 0.6g / L, MgSO 4 0.4g / L, K 2 HPO 4 0.3g / L, KH 2 PO 4 0.2g / L, CaCl 2 0.1g / L, the balance is water; the fermentation medium is 15g / L sucrose, 8g / L glucose, 4g / L b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com