Complete-synthesized rolling fluid and preparation method thereof

A rolling fluid, fully synthetic technology, applied in lubricating compositions, petroleum industry, etc., to achieve long service life, simple wastewater treatment, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0039] Weigh 10 parts of triethanolamine, 5 parts of isopropanolamine, 2 parts of sebacic acid, 1 part of neodecanoic acid, 4 parts of RPE17404, 2 parts of pripol10172 parts, 2 parts of boric acid and 10 parts of pure water, and heat to 70-80 °C , stir evenly, and then keep warm for 30 minutes while stirring, then add 55 parts of pure water to the above solution by weight ratio, then add 8 parts of LP-700, 1,3,5-tris(2-hydroxyethyl)-hexa Stir 1 part of hydrogen-triazine evenly to obtain the finished product. The performance of the finished product is shown in Table 1.

example 2

[0041] Weigh 7 parts of triisopropanolamine, 3 parts of monoethanolamine, 3 parts of undecanedibasic acid, 3 parts of isononanoic acid, 2 parts of RPE17202, 3 parts of PE6400, 3 parts of DIACID15503, 2 parts of boric acid and 10 parts of pure water , heated to 70-80°C, stirred evenly, and then kept warm for 30 minutes while stirring, then, added 56.5 parts of pure water to the above solution by weight ratio, and then added W58826 parts, 1,2-benzisothiazole-3- 1.5 parts of ketone are stirred evenly to obtain the finished product. The performance of the finished product is shown in Table 1.

example 3

[0043] Weigh 10 parts of diisopropanolamine, 5 parts of triethanolamine, 5 parts of undecanedibasic acid, 1 part of tall oil fatty acid, 4 parts of RPE17404, 2 parts of PE6100, 183 parts of UNIDYME, 2 parts of boric acid and 10 parts of pure water part, heated to 70-80°C, stirred evenly, then kept warm for 30 minutes while stirring, then, added 53.2 parts of pure water to the above solution by weight ratio, then added 4 parts of LB-400, 3-iodo-2-propyne 0.8 parts of butyl carbamate were stirred evenly to obtain the finished product. The performance of the finished product is shown in Table 1.

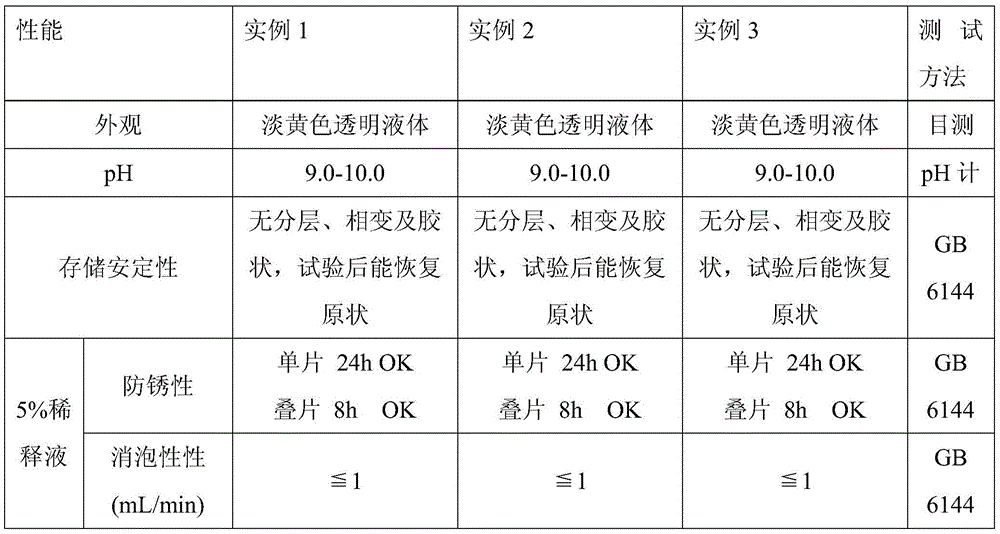

[0044] The performance parameter table of the composition obtained in the embodiment of table 1

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com