Multilayer chip varistor and preparation method thereof

A varistor, multi-layer chip technology, applied in the direction of varistor core, varistor, thin film varistor, etc. Cost and other problems, to reduce the preparation cost, avoid uneven thickness and sawtooth phenomenon, and achieve the effect of good aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the purpose, features and advantages of the present invention more clearly expressed, the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

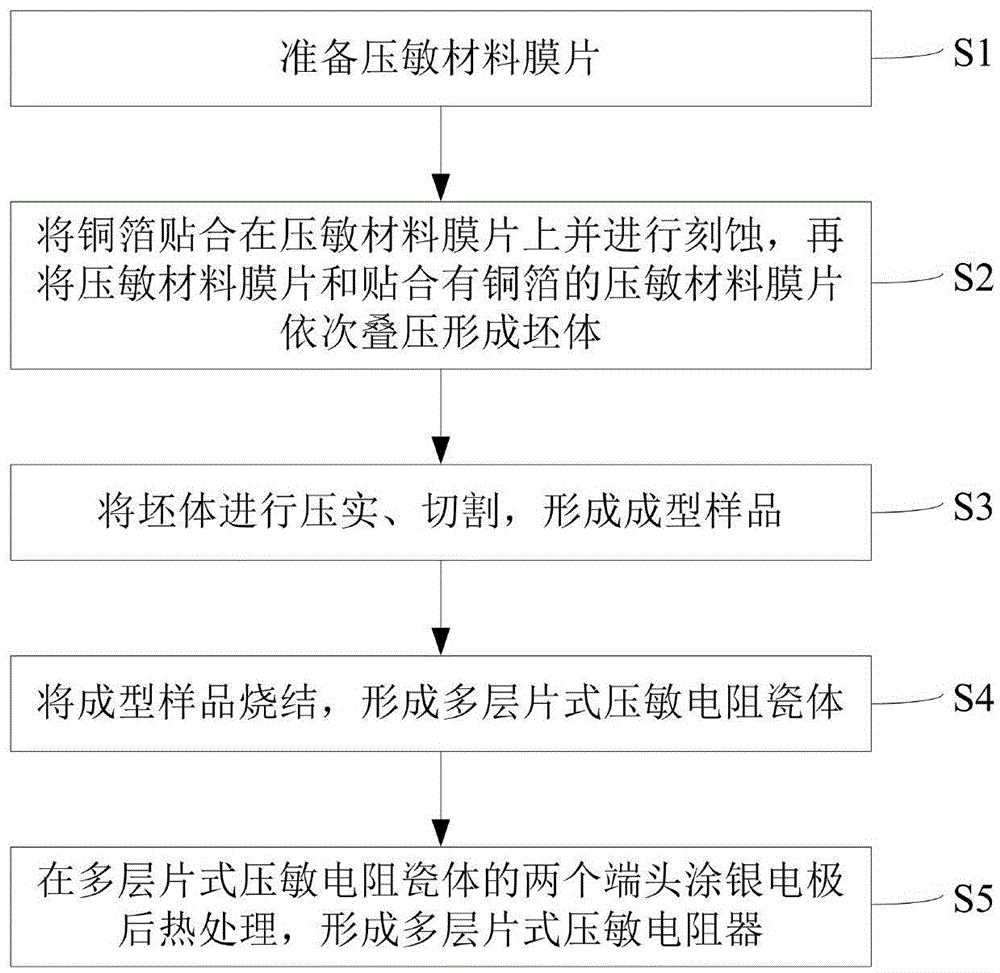

[0031] Such as figure 1 As shown, an embodiment of the present invention discloses a method for preparing a multilayer chip varistor, comprising the following steps:

[0032] S1: preparing a pressure-sensitive material diaphragm;

[0033] S2: Paste the copper foil on the pressure-sensitive material film and perform etching, and then laminate the pressure-sensitive material film and the pressure-sensitive material film with copper foil in sequence to form a green body; among them, copper foil is preferred The thickness is 1-3μm;

[0034] S3: compacting and cutting the green body to form a molded sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com