High voltage power distribution cabinet with good shielding performance

A high-voltage power distribution cabinet, shielding performance technology, applied in the fields of magnetic field/electric field shielding, electrical components, layered products, etc., can solve problems such as inconvenience of use, reduce the interference of electrical equipment, excellent shielding efficiency, high permeability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A high-voltage power distribution cabinet with good shielding performance, the surface of the high-voltage power distribution cabinet (10) is pasted with an electromagnetic shielding cover (20), and the cover (20) is made of permalloy plate (01) and The foamed aluminum-copper-nickel alloy (02) realizes the electromagnetic shielding function, and at the same time, the surface of the cover (20) is treated with hydrochloric acid to form a super-hydrophobic structure of nanosheets, which plays a role of self-cleaning and anti-corrosion protection.

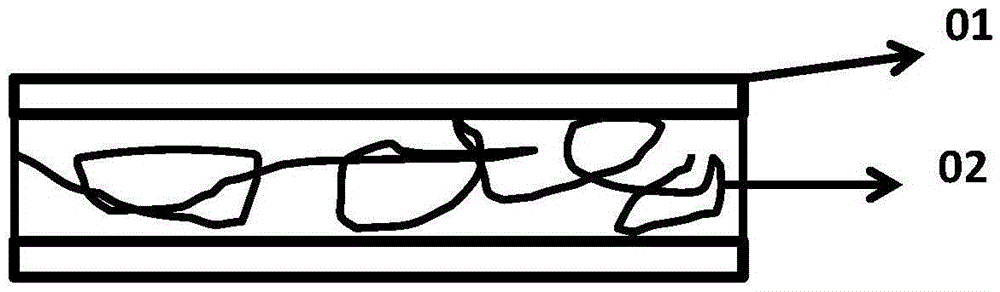

[0045]The cover body is a sandwich structure, specifically two layers of permalloy plates (01) sandwiching a layer of foamed aluminum-copper-nickel alloy (02); the thickness of the permalloy plate (01) is 0.5mm, the The surface of the permalloy plate (01) is covered by a nanosheet structure; the ratio of Ni and Fe in the permalloy plate (01) is 2:3, and the mass fractions of 0.5% and 1% of Mo and Si elements are added The thickn...

Embodiment 2

[0070] A high-voltage power distribution cabinet with good shielding performance, the surface of the high-voltage power distribution cabinet (10) is pasted with an electromagnetic shielding cover (20), and the cover (20) is made of permalloy plate (01) and The foamed aluminum-copper-nickel alloy (02) realizes the electromagnetic shielding function, and at the same time, the surface of the cover (20) is treated with hydrochloric acid to form a super-hydrophobic structure of nanosheets, which plays a role of self-cleaning and anti-corrosion protection.

[0071] The cover body is a sandwich structure, specifically two layers of permalloy plates (01) sandwiching a layer of foamed aluminum-copper-nickel alloy (02); the thickness of the permalloy plate (01) is 0.5mm, the The surface of the permalloy plate (01) is covered by a nanosheet structure; the ratio of Ni and Fe in the permalloy plate (01) is 2:3, and the mass fractions of 0.5% and 1% of Mo and Si elements are added The thick...

Embodiment 3

[0096] A high-voltage power distribution cabinet with good shielding performance, the surface of the high-voltage power distribution cabinet (10) is pasted with an electromagnetic shielding cover (20), and the cover (20) is made of permalloy plate (01) and The foamed aluminum-copper-nickel alloy (02) realizes the electromagnetic shielding function, and at the same time, the surface of the cover (20) is treated with hydrochloric acid to form a super-hydrophobic structure of nanosheets, which plays a role of self-cleaning and anti-corrosion protection.

[0097]The cover body is a sandwich structure, specifically two layers of permalloy plates (01) sandwiching a layer of foamed aluminum-copper-nickel alloy (02); the thickness of the permalloy plate (01) is 0.5mm, the The surface of the permalloy plate (01) is covered by a nanosheet structure; the ratio of Ni and Fe in the permalloy plate (01) is 2:3, and the mass fractions of 0.5% and 1% of Mo and Si elements are added The thickn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Electromagnetic shielding effectiveness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com