High-wheat-bran dietary fiber bread flour

A technology for wheat bran dietary fiber and dietary fiber, which is applied in the field of high wheat bran dietary fiber bread flour, can solve the problems of poor bread swelling and rough structure, and achieve the effects of increasing gas retention, solving rough structure and increasing nutritional value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

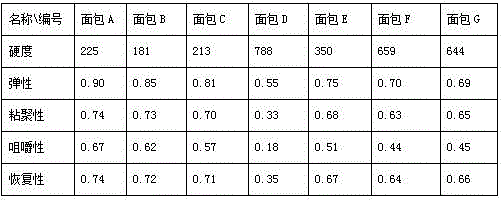

Examples

Embodiment 1

[0023] (1) Send 100kg of wheat bran into the solid tank;

[0024] (2) Dissolve 0.2-0.5kg of compound enzyme preparation in 45-55kg of distilled water; the mass ratio of compound enzyme preparation is: α-amylase: xylanase: cellulase: hemicellulase: pentosan enzyme=3:10:10:3:5;

[0025] (3) Add the compound enzyme solution prepared in step (2) to the wheat bran prepared in step (1), stir evenly, and enzymolyze at 37°C for 2-3 hours;

[0026] (4) Put steam into the solid tank, steam the material in the solid tank when the temperature is above 100°C for 15-25 minutes, then turn on the water circulation vacuum pump to reduce the temperature of the material in the solid tank to below 40°C;

[0027] (5) Release the material in the solid tank, and dry it through tunnel microwave until the moisture is not higher than 5wt%;

[0028] ⑹. The dried material is ultrafinely pulverized and passed through a 200-mesh sieve to obtain wheat bran fiber powder with a fineness of 200-300 mesh.

...

Embodiment 2

[0031] Take 75kg of high-gluten flour, 17kg of wheat bran fiber powder prepared in Example 1, 8kg of wheat gluten powder, and 0.3kg of improver to obtain high dietary fiber bread flour A; (optimum ratio)

[0032] Get high-gluten flour 85kg, wheat bran fiber powder 10kg prepared in embodiment 1, wheat gluten powder 2kg, improver 0.2kg, get high dietary fiber bread flour B;

[0033] Get high-gluten flour 65kg, wheat bran fiber powder 25kg prepared in embodiment 1, wheat gluten powder 10kg, improver 0.5kg, get high dietary fiber bread flour C;

[0034] The compound improver is composed of Vc, glucose oxidase, lipase, xylanase, cellulase, α-amylase and sodium stearoyl lactylate according to the mass ratio of 250:150:200:10:200:3:2000;

Embodiment 3

[0036] (1) Dissolve 192g of white sugar and 12g of salt in 680ml of water to obtain a sugar solution; divide the sugar solution into 4 parts on average;

[0037] (2) Take 300g of high dietary fiber bread flour A, B, and C respectively, add 3.5g of high-sugar yeast, and then add 1 portion of sugar solution under stirring conditions; then stir slowly for 3 minutes, and stir quickly for 1 minute; then add 24g butter, stir slowly for 3 minutes, and stir quickly for 1 minute; manually beat the dough until the film is thin and uniform, without filaments, and the edge of the break is smooth without jagged; obtain dough A, B, and C respectively;

[0038] (3) Dough A, B, C, covered with plastic sheeting, and let stand for 5 minutes; then divide dough A, B, and C into two 150g and two 90g dough pieces respectively, knead round, cover with plastic sheet and let stand for 5 minutes ;

[0039] (4) Proof the formed dough in the proofing box for 2.5 hours, set the temperature of the proofin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com