Preparation method of xylene isomerization catalyst

A catalyst and isomerization technology, used in isomerization for hydrocarbon production, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve the problems of increased coking and increased acid strength, and achieve the effect of improving activity and high achievement rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0030] (1) Preparation of acid-modified ZSM-5 molecular sieves.

[0031] Take 14 grams of SiO 2 / Al 2 o 3 NaZSM-5 molecular sieve with a molar ratio (silicon-aluminum ratio) of 90 was ion-exchanged at 90°C for 2 hours with 50 ml of ammonium chloride aqueous solution with a concentration of 2% by mass, washed until there was no chloride ion in the washing liquid, and dried at 120°C for 6 hours, and calcined at 550°C for 4 hours to obtain HZSM-5 molecular sieve. Put the HZSM-5 molecular sieve into hydrochloric acid with a concentration of 0.25 mol / liter, soak it at 90°C for 4 hours, the impregnating liquid / solid ratio is 5mL / g, wash the impregnated solid with water until the washing liquid has no chloride ions, and dry at 120°C After 8 hours, an acid-modified molecular sieve was obtained.

[0032] (2) Preparation of catalyst

[0033] Take the above-mentioned acid-modified molecular sieve and 6 grams of alumina and mix well, add 20 milliliters of nitric acid solution with a ...

example 2

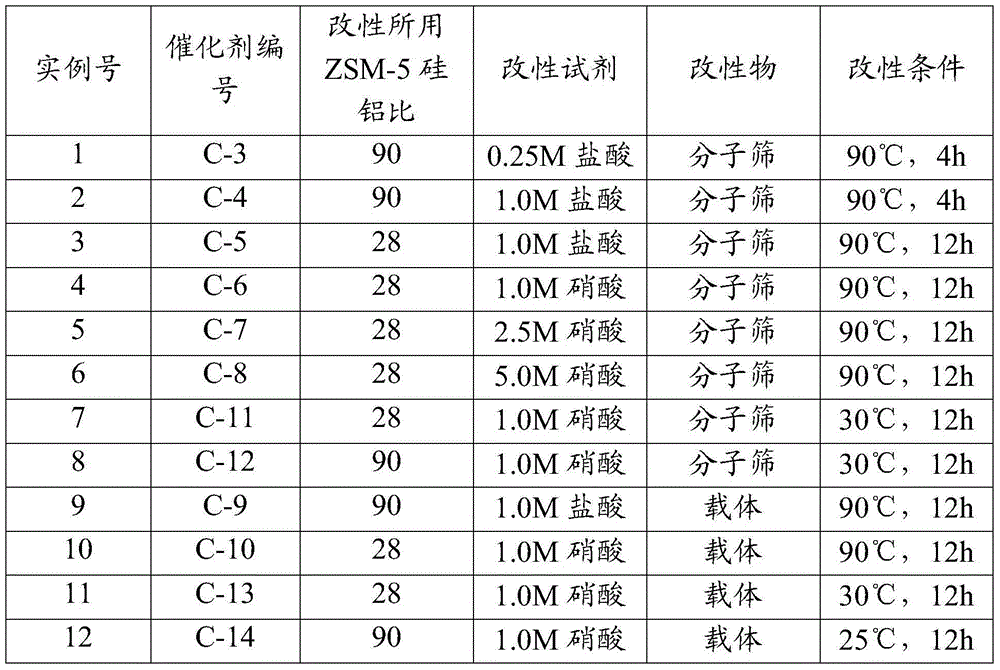

[0036] Prepare catalyst by the method for example 1, difference is (1) the concentration of hydrochloric acid used is 1.0 mol / liter, makes catalyst C-4, and wherein platinum content is 0.02 mass %, and carrier contains the acid-modified molecular sieve of 70 mass % and 30% by mass of alumina. The reagents and conditions used for acid modification are listed in Table 1.

example 3

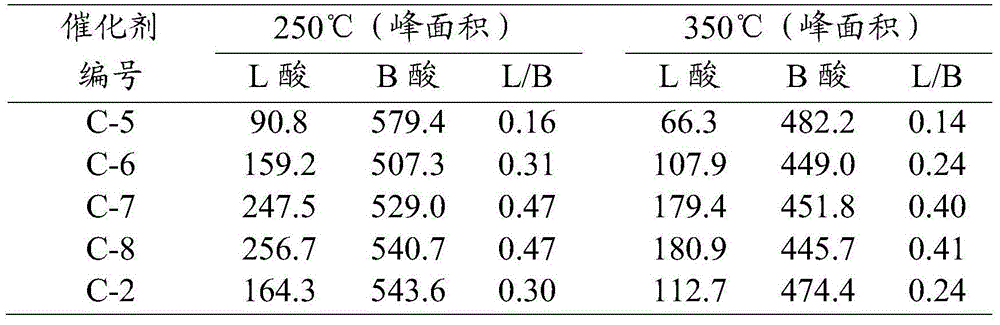

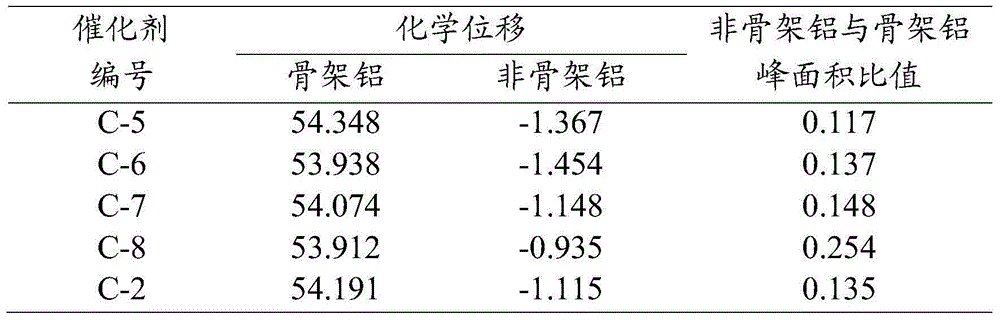

[0038] Prepare catalyst by the method for example 1, difference is (1) step used NaZSM-5 molecular sieve SiO 2 / Al 2 o 3 The molar ratio was 28, and the prepared HZSM-5 molecular sieve was modified by impregnating it with 1.0 mol / L hydrochloric acid at 90° C. for 12 hours. The acid-modified molecular sieve was prepared as a catalyst according to the step method of Example 1 (2) to obtain catalyst C-5, wherein the platinum content was 0.02% by mass, and the carrier contained 70% by mass of acid-modified molecular sieve and 30% by mass of alumina. The reagents and conditions used for acid modification are listed in Table 1, and the catalyst acid distribution measured at different temperatures by pyridine adsorption method is shown in Table 2; 27 The changes of framework aluminum and non-framework aluminum determined by Al NMR are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com