Amorphous magnesium-aluminum-base composite hydrogen storage material and preparation method thereof

A hydrogen storage material, magnesium-aluminum-based technology, applied in the field of lightweight hydrogen storage materials, can solve the problem of high hydrogen desorption temperature of magnesium-based hydrogen storage materials, avoid weakening of diffusion capacity, refine particle/grain size, accelerate The effect of hydrogen storage process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

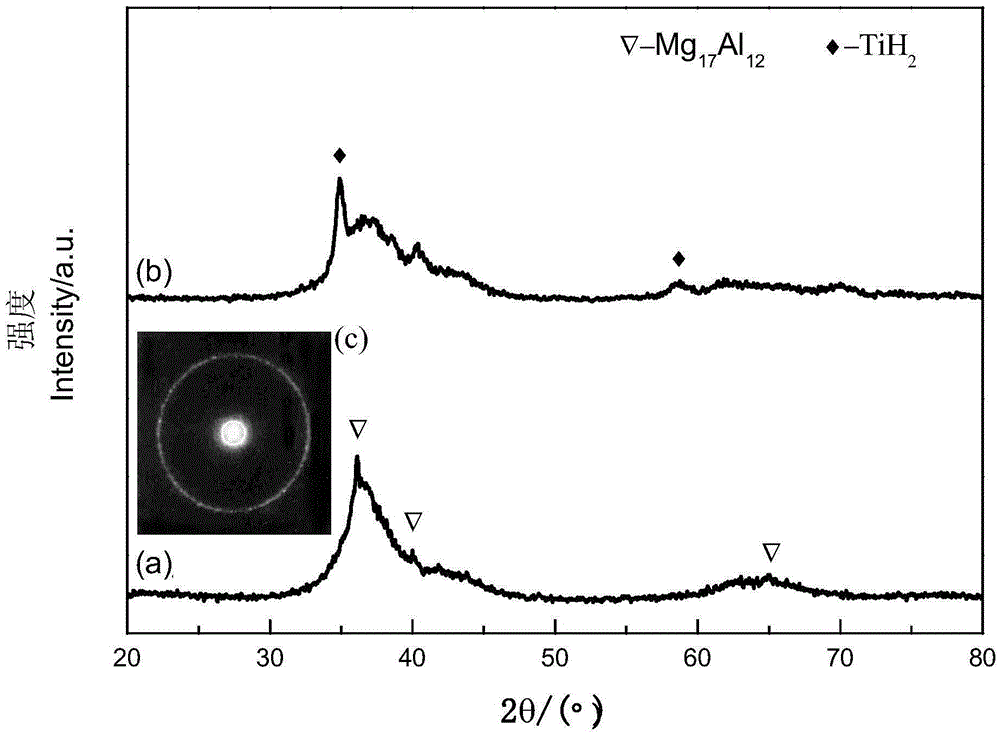

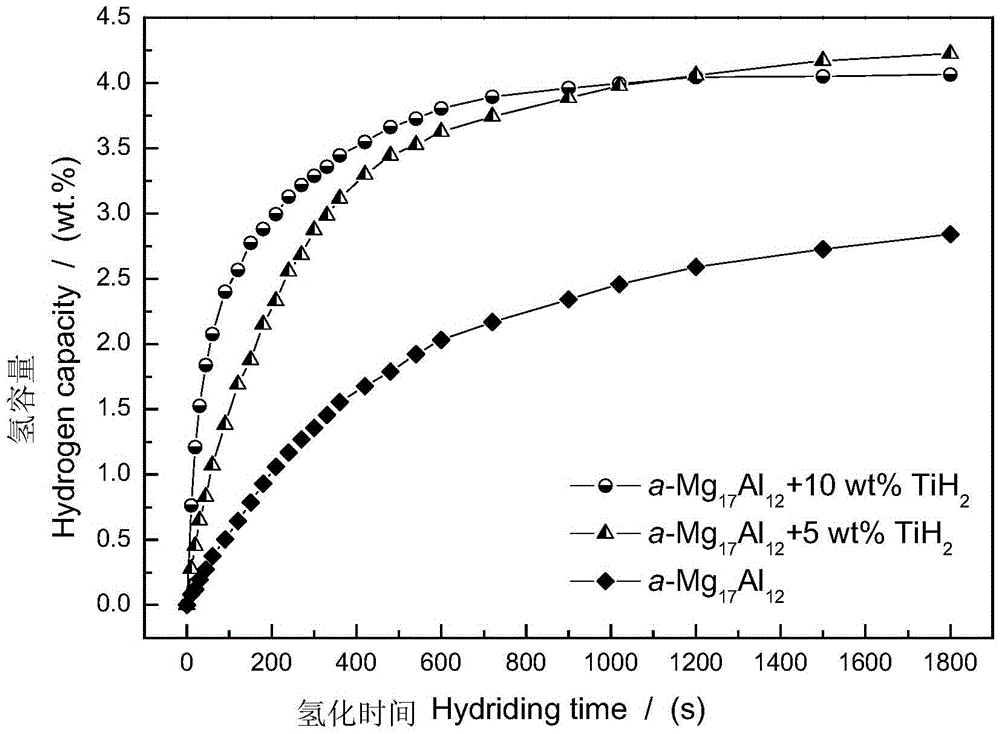

Embodiment 1

[0030] According to Mg 17 al 12 The composition ratio of the alloy, the raw materials are Mg and Al powders with a particle size of 74-154 μm and a purity of 99%. 17 al 12 Mix the proportions evenly and place them in a double-layer ball mill tank in a ball mill controlled by ice and salt water, and ball mill at 0°C for 50 hours to prepare amorphous Mg 17 al 12 Base powder material. Subsequently, the transition metal hydride of choice was TiH 2 powder, with a purity of 99%, the prepared amorphous Mg 17 al 12 Base powder and accounted for the Mg 17 al 12 The total amount of matrix is 10wt.% TiH 2 The powder was mechanically ball milled at room temperature 25°C for 20 hours, the protective atmosphere of the ball mill was argon with a purity of 99.99%, the pressure of the protective atmosphere was 0.2MPa, the ball-to-material ratio during the ball milling process was 40:1, and the ball mill speed was 450rpm, and finally prepared Amorphous a-Mg 17 al 12 +10wt.%TiH 2 ...

Embodiment 2

[0033] According to Mg 17 al 12 The composition ratio of the alloy, the raw materials are Mg and Al powders with a particle size of 74-154 μm and a purity of 99%. 17 al 12 Mix the proportions evenly and place it in a double-layer ball mill tank in a ball mill controlled by ice salt water, and ball mill at -1°C for 50h to prepare amorphous Mg 17 al 12 Base powder material. Subsequently, the transition metal hydride of choice was TiH 2 powder, with a purity of 99%, the prepared amorphous Mg 17 al 12 Base powder and accounted for the Mg 17 al 12 The total amount of matrix is 8wt.% TiH 2 The powder was mechanically ball milled at room temperature 25°C for 30 hours, and other preparation processes were the same as in Example 1, and finally amorphous a-Mg was prepared 17 al 12 +8wt.%TiH 2 Magnesium-based composite hydrogen storage materials.

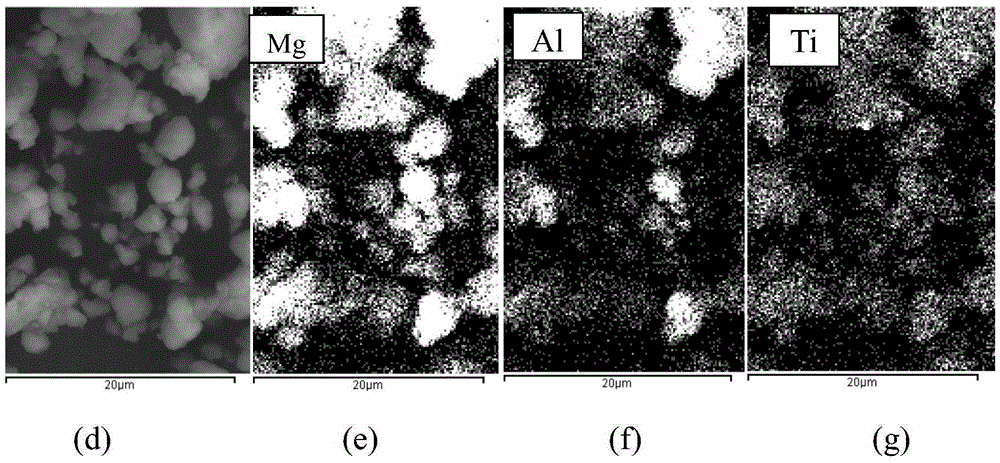

[0034] For the analysis of amorphous a-Mg 17 al 12 with TiH 2 The composite situation of the sample is analyzed by energy s...

Embodiment 3

[0036] According to Mg 17 al 12 The composition ratio of the alloy, the raw materials are Mg and Al powders with a particle size of 74-154 μm and a purity of 99%. 17 al 12 Mix the proportions evenly and put them in a double-layer ball mill tank in a ball mill with ice salt water for temperature control, and ball mill at -5°C for 35 hours to prepare amorphous Mg 17 al 12 Base powder material. Subsequently, the transition metal hydride of choice was TiH 2 powder, with a purity of 99%, the prepared amorphous Mg 17 al 12 Base powder and accounted for the Mg 17 al 12 The total amount of matrix is 10wt.% TiH 2 The powder was mechanically ball milled at room temperature 25°C for 2 hours, the protective atmosphere of the ball mill was hydrogen with a purity of 99.99%, the pressure of the protective atmosphere was 2.5MPa, the ball-to-material ratio during the ball milling process was 20:1, and the ball mill speed was 200rpm. Crystalline a-Mg 17 al 12 +10wt.%TiH 2 Magnesi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com