Waterborne non-sticky bactericidal coating

A bactericidal coating, water-based technology, applied in antifouling/underwater coatings, fire-retardant coatings, coatings, etc., can solve the problem that the non-stick performance of water-based non-stick coatings is difficult to meet the increasingly high non-stick requirements, increase energy consumption, Increase the investment of temperature and humidity control equipment, etc., to achieve the effect of super redox ability, excellent adhesion, and good sterilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

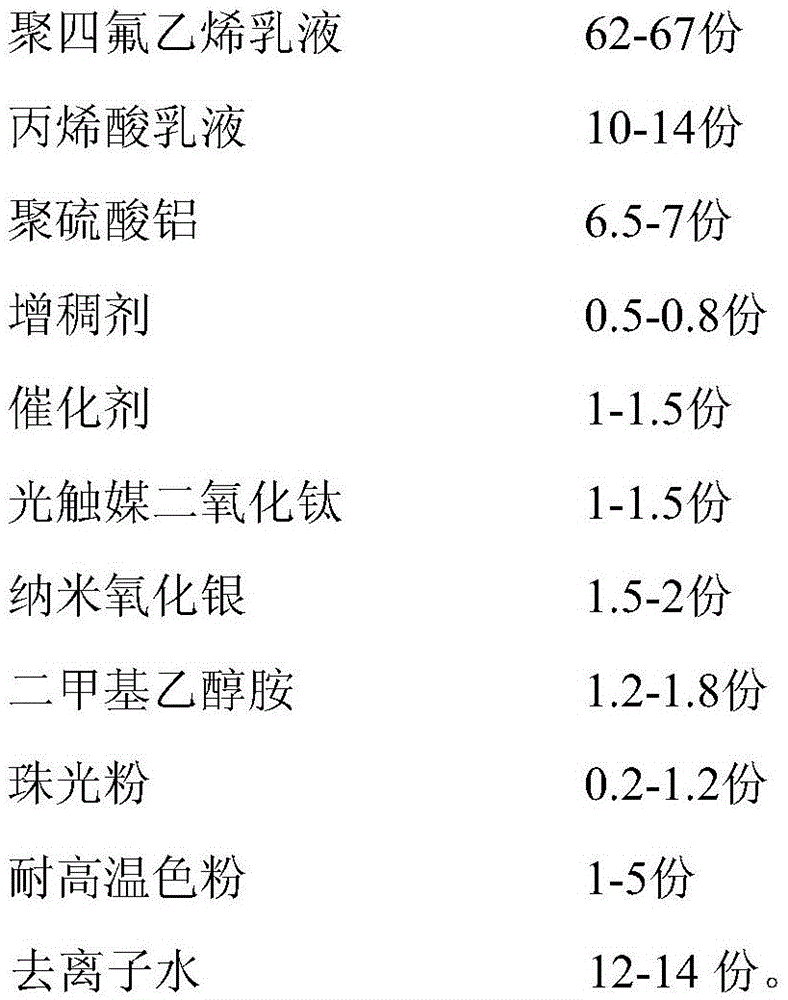

Embodiment 1

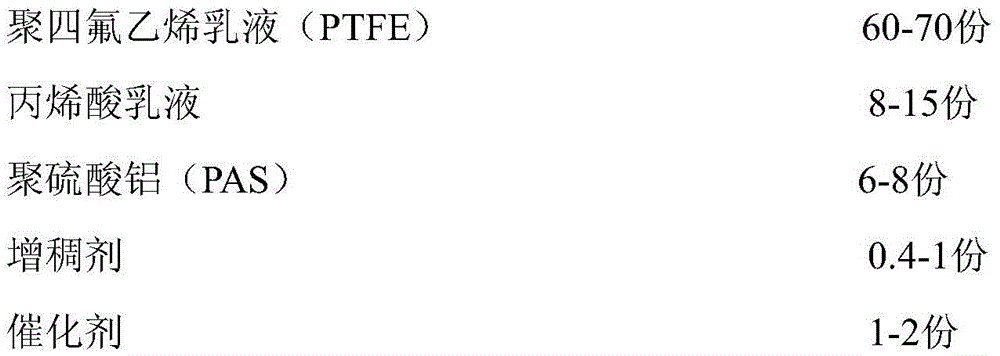

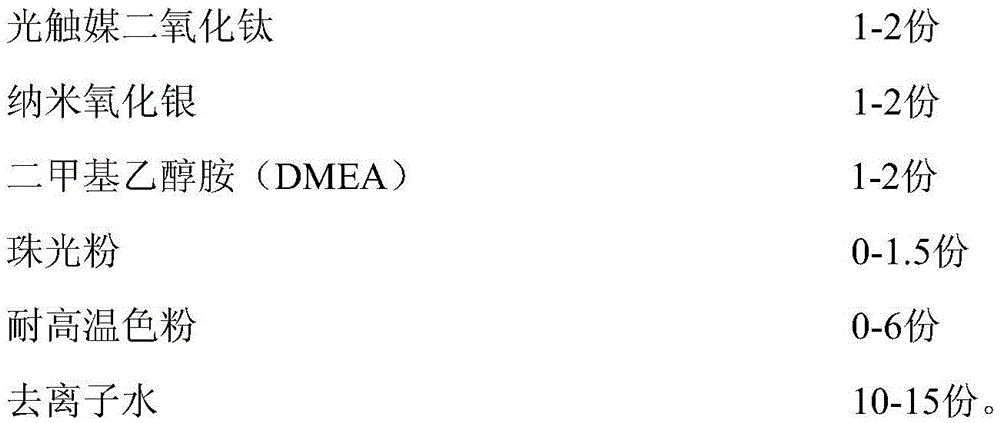

[0034] A water-based non-stick bactericidal coating is mainly prepared from the following raw materials:

[0035] 600g of polytetrafluoroethylene emulsion; 80g of acrylic emulsion; 60g of polyaluminum sulfate; 4g of polyurethane thickener; 10g of organic cerium catalyst; 20g of photocatalyst titanium dioxide;

Embodiment 2

[0037] A water-based non-stick bactericidal coating is mainly prepared from the following raw materials:

[0038] Polytetrafluoroethylene emulsion 700g; Acrylic emulsion 150g; Polyaluminum sulfate 80g; Polyurethane thickener 10g; Organic cerium catalyst 20g; Photocatalyst titanium dioxide 10g; Nano silver oxide 20g; Dimethylethanolamine 20g; ; Deionized water 150g.

Embodiment 3

[0040] A water-based non-stick bactericidal coating is mainly prepared from the following raw materials:

[0041] 620g of polytetrafluoroethylene emulsion; 100g of acrylic emulsion; 65g of polyaluminum sulfate; 5g of cellulose thickener; 10g of polymer metal complex catalyst; 10g of photocatalyst titanium dioxide; ; Oxygen complex green powder 10g; deionized water 120g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com