Low-viscosity high-transparency self-adhesive organic silicone pouring sealant and preparation method thereof

A silicone potting glue and self-adhesive technology, applied in the field of potting glue, can solve the problems of poor adhesion of the potting glue, increase the production process, high viscosity, achieve good bonding performance and mechanical properties, easy industrial production, Simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

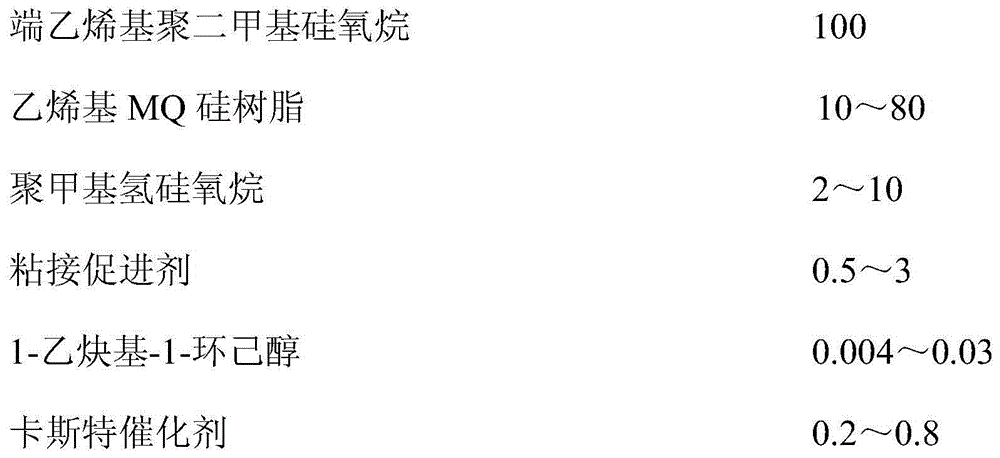

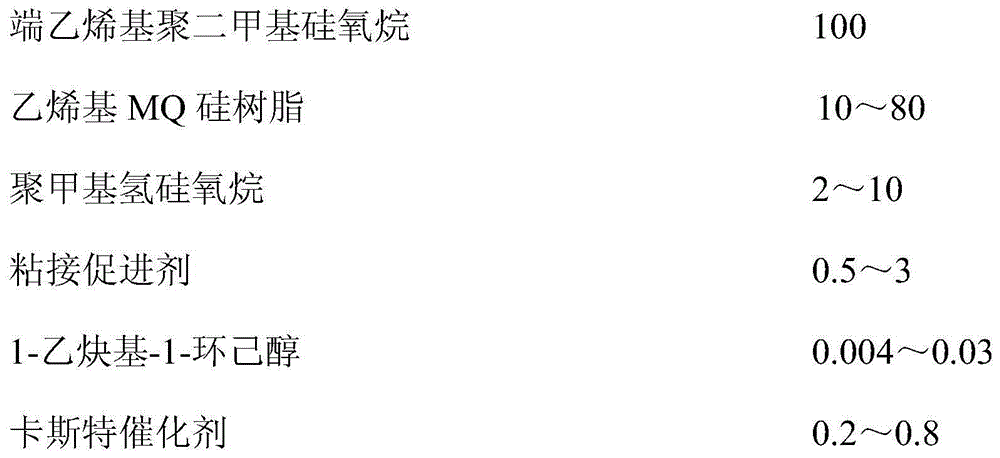

Method used

Image

Examples

Embodiment 1

[0020] 100 parts by mass of vinyl-terminated polydimethylsiloxane with a viscosity of 1000 mPa·s, 20 parts by mass of vinyl-based MQ silicone resin (vinyl content of 0.5%, M / Q value of 0.8), and 4.5 parts by mass of a viscosity of 50mPa·s polymethylhydrogensiloxane, 1.5 parts by mass of vinyltrimethoxysilane, 0.02 parts by mass of 1-ethynyl-1-cyclohexanol and 0.3 parts by mass of a platinum catalyst with a content of 4000ppm were added to the high-speed disperser, Stir for 1 hour to obtain a low-viscosity, highly transparent, self-adhesive silicone potting compound. Its performance test shows that the viscosity is 1500mPa·s, the light transmittance is 97%, and the bond tensile shear strength (abbreviated as shear strength, the same below) is 1.02MPa. The detailed results are shown in Table 1.

Embodiment 2

[0022] 100 parts by mass of vinyl-terminated polydimethylsiloxane with a viscosity of 800 mPa·s, 30 parts by mass of vinyl MQ silicone resin (vinyl content is 1%, M / Q value is 1), 5 parts by mass with a viscosity of 30mPa·s polymethylhydrogensiloxane, 2 parts by mass of vinyltrimethoxysilane, 0.01 part by mass of 1-ethynyl-1-cyclohexanol and 0.4 parts by mass of a platinum catalyst with a platinum content of 2500ppm were added to the high-speed disperser, Stir for 2 hours to obtain a low-viscosity, highly transparent, self-adhesive silicone potting compound. Its performance test shows that the viscosity is 1800mPa·s, the light transmittance is 97%, and the shear strength is 1.15MPa. The detailed results are shown in Table 1.

Embodiment 3

[0024] 100 parts by mass of vinyl-terminated polydimethylsiloxane with a viscosity of 2000mPa·s, 15 parts by mass of vinyl-based MQ silicone resin (vinyl content of 6.5%, M / Q value of 1.2), and 7.5 parts by mass of a viscosity of 150mPa·s polymethylhydrogensiloxane, 1.5 parts by mass of 3-methacryloxypropyltrimethoxysilane, 0.02 parts by mass of 1-ethynyl-1-cyclohexanol and 0.2 parts by mass of platinum with a content of 5000ppm Add the Ster catalyst into a high-speed disperser and stir for 3 hours to obtain a low-viscosity, high-transparency, self-adhesive silicone potting compound. Its performance test shows that the viscosity is 2300mPa·s, the light transmittance is 98%, and the shear strength is 1.03MPa. The detailed results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com