A lithium-based lubricating grease composition with excellent wear resistance and a preparing method thereof

A technology of grease composition and lithium-based grease, which is applied in the field of grease, can solve the problems of poor water resistance, poor anti-wear performance, poor oxidation resistance, etc., achieve good high temperature resistance, improve wear reduction ability and The effect of antioxidant capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] Among the present invention, the preparation method of the compound of structure shown in formula (I) preferably comprises:

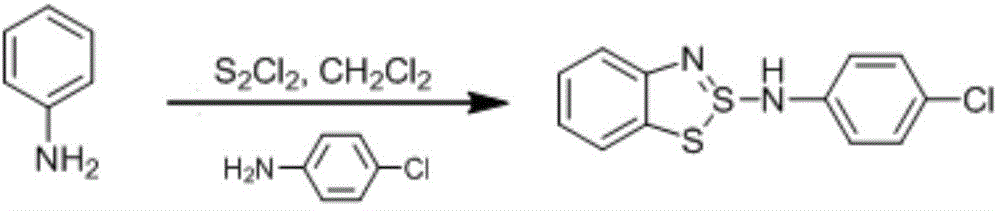

[0047] (a) react aniline, sulfur chloride and 4-chloroaniline to generate intermediate M shown in formula (II),

[0048]

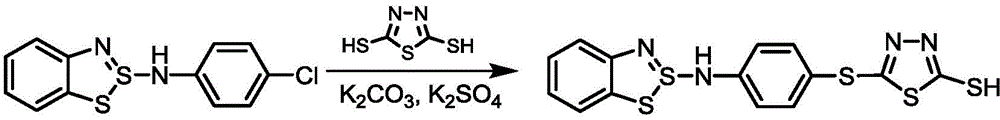

[0049] (b) carrying out nucleophilic substitution reaction between the intermediate M obtained in step (a) and dimercapto-1,3,4-thiadiazole under alkaline conditions to generate the multi-effect additive shown in formula (I),

[0050]

[0051] In step (a) of the present invention, the specific mode of reacting aniline, sulfur chloride and 4-chloroaniline preferably includes:

[0052] (i) fully reacting aniline and sulfur chloride at -20-0°C in the first solvent under an inert atmosphere;

[0053] (ii) Add 4-chloroaniline into the reaction system of step (i), and react at 15-30° C. for 1-3 h.

[0054] In the present invention, the inert atmosphere can be a conventional inert atmosphere in the field, for example, it can...

Embodiment

[0092] The following examples will further illustrate the present invention, but do not limit the present invention thereby.

[0093] In the following examples and comparative examples:

[0094] The method for monitoring the complete reaction: thin-layer chromatography (TLC) fluorescence color method.

[0095] Total yield = molar amount of final product / molar amount of aniline × 100%

[0096] The physical and chemical analysis method of the product: the element content was determined by inductively coupled plasma ion emission spectrometry.

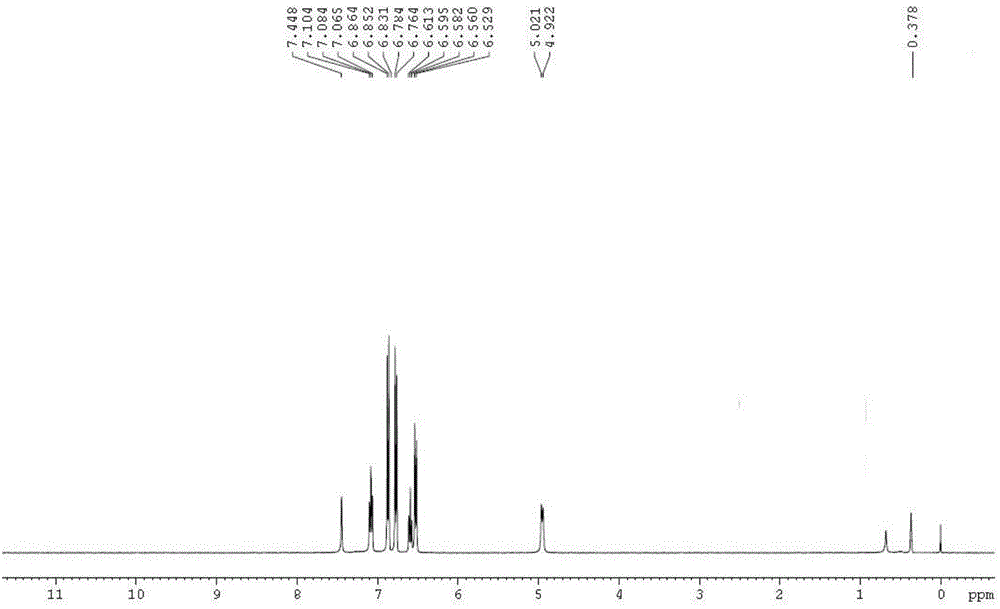

[0097] Structural characterization method: NMR method ( 1 H spectrum, 13 C carbon spectrum), high-resolution mass spectrometry.

preparation example

[0099] Fill a 500ml flask with an electromagnetic stirrer (stirring speed is 300rpm) with nitrogen protection, add 150ml of dichloromethane, then add 0.2mol of sulfur chloride, fully cool in an ice-water bath, add 0.2mol of aniline . Remove the ice-water bath after monitoring until the reaction is complete, and place it at room temperature of 25°C. After the reaction system gradually rises to 25°C, add 4-chloroaniline in 3 times for reaction. The amount added each time is the same, and 4-chloroaniline is added in total 0.15mol. After the reaction was continued for 2 hours, 30ml of saturated brine was added to quench the reaction, and then the reaction system was transferred to a separatory funnel, washed with 50ml of distilled water and 50ml of saturated brine, and dried by adding 10g of anhydrous lithium sulfate at 25°C for 20min. The filtered filtrate was evaporated to remove the solvent at 40° C. and 0.05 MPa to obtain intermediate M1.

[0100] Fill a 500ml flask with an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com