Composition and depolymerization method for lignocellulose depolymerization

A technology of lignocellulose and depolymerization, applied in biochemical equipment and methods, enzymes, enzymes, etc., can solve problems such as less obvious synergy, little guiding significance, and unclear mechanism of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Isolate and purify the dehydrogenase in the composition of the present invention from the extracellular enzyme liquid of Penicillium juniper:

[0038] Penicillium piceum (Penicillium piceum) H16, preservation number: CGMCC No.8339, preservation unit China General Microbiological Culture Collection Center (China General Microbiological Culture Collection Center).

[0039] For Penicillium juniper, the optimum medium conditions are as follows: 3.3% microcrystalline cellulose, 1.7% corncob steep liquor, 0.5% (NH4) 2 SO 4 , 0.6% KH 2 PO 4 , 0.1% MgSO 4 , 0.25% CaCO 3 , and 0.2% Tween-80. The glass container used for fermentation generally chooses a 300mL Erlenmeyer flask, cultivates 50mL of the culture medium, and shakes it horizontally at 180rpm in a 28-degree incubator for 5 days.

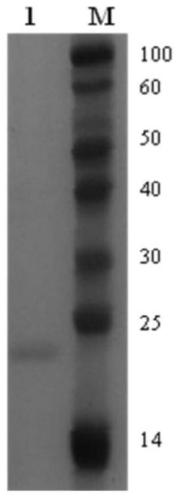

[0040] The instrument used for separation and purification of dehydrogenase is AKTA purifier (GE, Sweden). Using acetic acid-sodium acetate solution with a pH value of 4.8-5.0 and a subst...

Embodiment 2

[0043] Enzyme activity assay of dehydrogenase:

[0044] Application of the conventional methods in the art cellulase and hemicellulase national standard assay method composition-dehydrogenase to carboxymethylcellulose (CMC-Na), salicin (Salicin), PNPC, microcrystalline cellulose ( Avicel), xylan (Xylan), PNPG, and cellobiose were tested for enzyme activity, and the test results are shown in Table 1 below: the composition was found to have no glycoside hydrolase activity.

[0045] Table 1. Preliminary analysis of enzymatic properties of dehydrogenases

[0046]

Embodiment 3

[0048] Research on the mechanism of action of the dehydrogenase of the present invention

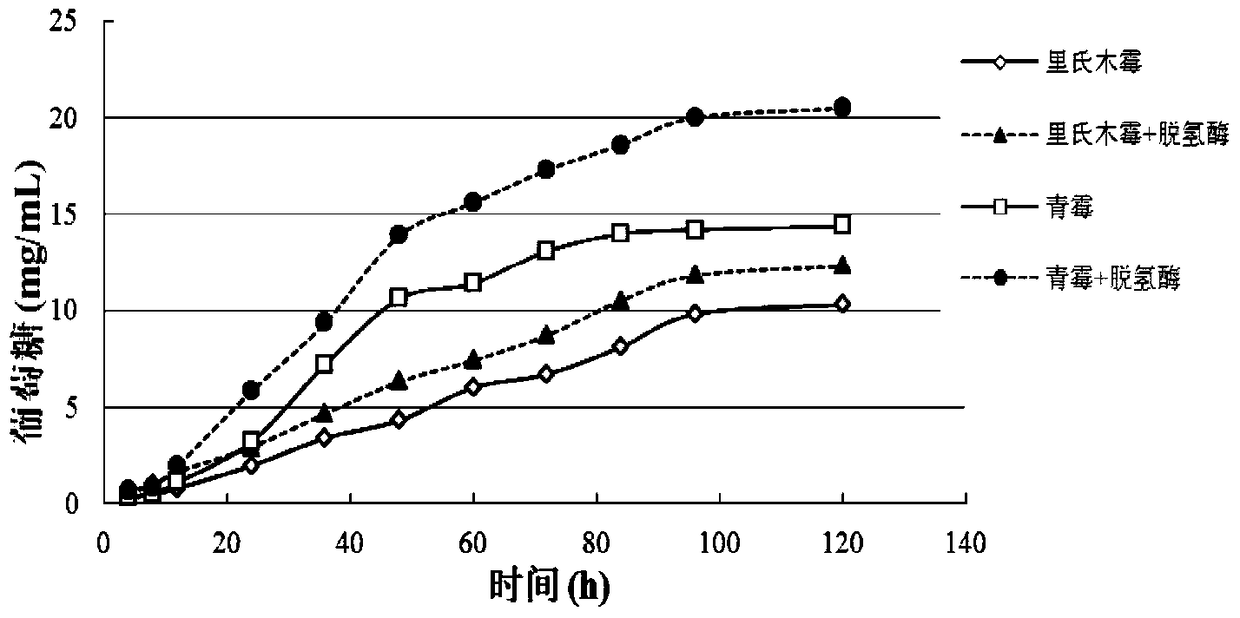

[0049] When dehydrogenase was added to the crude enzyme solutions of Trichoderma reesei and Penicillium juniperus at a protein concentration of 40 μg / mL, the hydrolysis efficiencies of the crude enzyme solutions of Trichoderma reesei and Penicillium juniperi increased by 27% and 35%, respectively. %. This is the first time that a dehydrogenase has been found in a cellulase system. The dehydrogenase itself has no enzymatic activity, and there is a strong synergistic effect with the cellulase, so the dehydrogenase belongs to the cellulase synergistic composition, such as figure 2 shown.

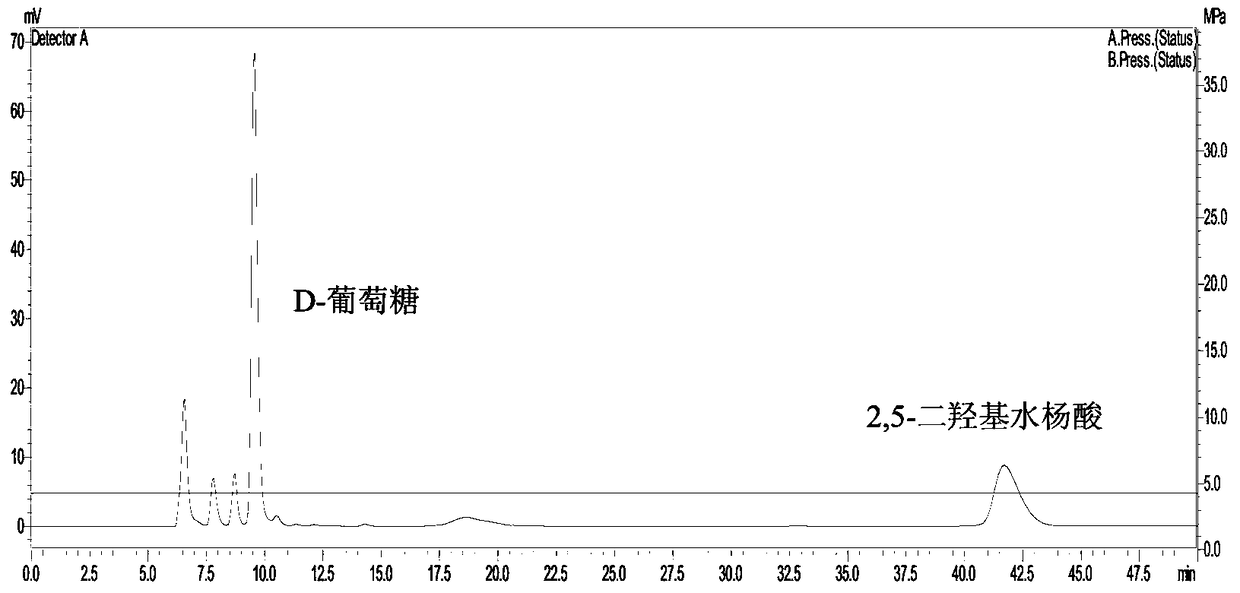

[0050] The dehydrogenase protein did not detect hydrolase activity, but when it treated four kinds of lignocellulosic materials with different components, when the hydrolyzate was analyzed by HPLC-42A, it was found that there was a small amount of D-glucose and D-glucose in the hydrolyzate - Sorbitol, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com