A kind of asphalt pavement stress reflection crack repair material and repair method

A technology for reflecting cracks and asphalt pavement, applied in building insulation materials, roads, roads, etc., can solve problems such as poor flow permeability, high viscosity of modified asphalt, secondary damage, etc., to improve stability, enhance penetration, and improve The effect of high temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

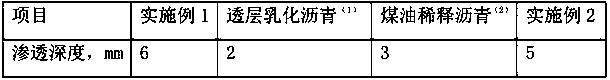

Embodiment 1

[0054] (1) Mix No. 93 gasoline, aviation kerosene and No. 0 diesel oil according to the mass ratio of 2:1:0.4 to prepare diluent for use.

[0055] (2) Zhenhai SBS modified asphalt (60%) with a penetration degree (25°C, 0.1mm) of 61, stop heating after heating to 140°C, and add alkyl polyoxyethylene ether (4%) under stirring 5 minutes. Finally, add the configured diluent (36%) and stir for 15 minutes to obtain the high-permeability liquid asphalt of the present invention.

Embodiment 2

[0057] (1) Mix No. 93 gasoline, aviation kerosene and No. 0 diesel oil according to the mass ratio of 1.5:1:0.4 and prepare it as a diluent for use.

[0058] (2) Heat the Zhenhai Grade A bitumen (70%) with a penetration (25°C, 0.1mm) of 61 to 120°C, stop heating, add the prepared diluent (28%) while stirring, and stir for 5 minutes. Finally, add fatty alcohol polyoxyethylene ether (2%) and continue stirring for 20 minutes to obtain the high-permeability liquid pitch of the present invention.

[0059] Filling glue:

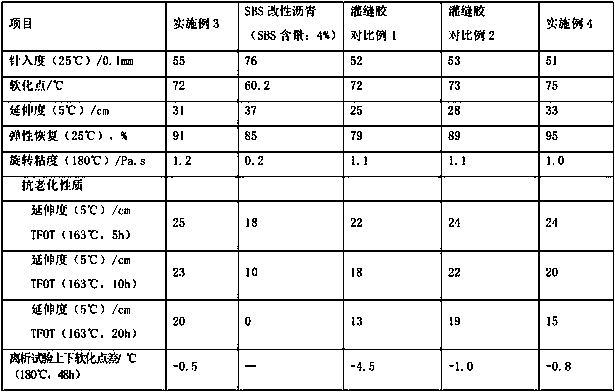

Embodiment 3

[0061] (1) Heat Zhenhai base asphalt (83%) with a penetration degree (25°C) of 110 to 180°C-190°C, add 60 mesh waste tire rubber powder (16%), and perform high-shear grinding for 2-3 times Stir in the development tank for 1 h,

[0062] (2) Add 1% slow-release chemical modifier (benzoyl peroxide), stir evenly, and then inject compressed air from the bottom of the tank. Air volume is 0.2 m 3 × kg -1 × h -1 . Stirring was continued for 1 hour, after which the blowing of compressed air was stopped.

[0063] (3) Add an equal amount of SBS modified asphalt (SBS content: 6%, penetration (25°C): 70 1 / 10mm) and continue stirring for 1 hour. Promptly obtain the caulking glue of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com