Lithium ion battery

A lithium-ion battery and electrochemical technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of complex process, low yield and high cost, and achieve a simple preparation process, high specific capacity and low manufacturing cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] 1. Configure ferric oxide electroplating solution

[0038] a, take exactly 9.997g of ferric sulfate (Fe 2 (SO 4 ) 3 ,0.025mol), add 200ml deionized water into the beaker to dissolve, stir well;

[0039] b. Accurately weigh 19.998g of sodium hydroxide (NaOH, 0.5mol) and 7.459g of triethanolamine (TEA, 0.05mol), add 200ml of deionized water to dissolve in a beaker, and stir evenly;

[0040] c. Add the solution in step a to the solution in step b, and dilute to volume in a 500ml volumetric flask;

[0041] d. Stir the prepared electroplating solution at room temperature for 48 hours until the solution is completely free of precipitation and turns light green.

[0042] After configuration, the concentration of each component of the electroplating solution is: 0.05 mol / L of iron sulfate, 1 mol / L of sodium hydroxide, and 0.1 mol / L of triethanolamine.

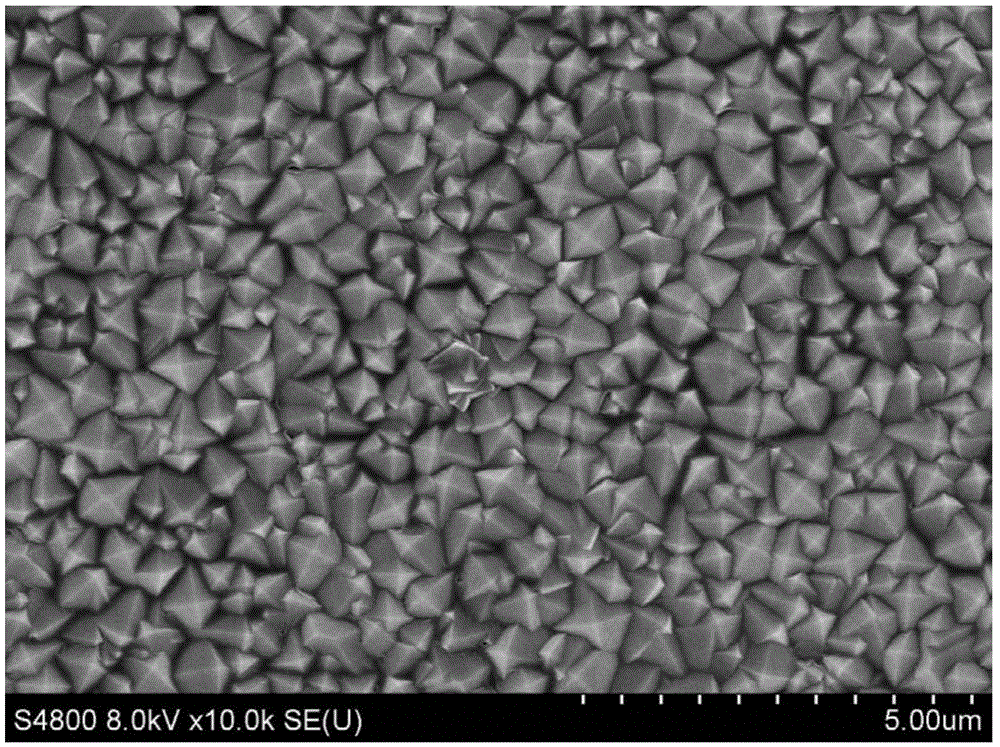

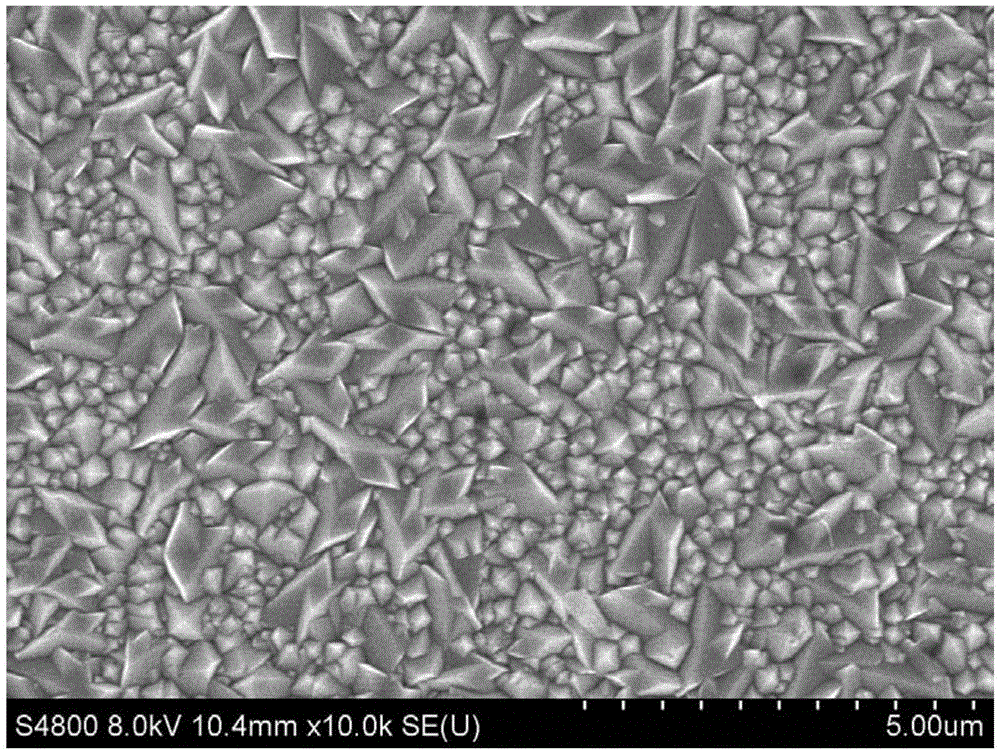

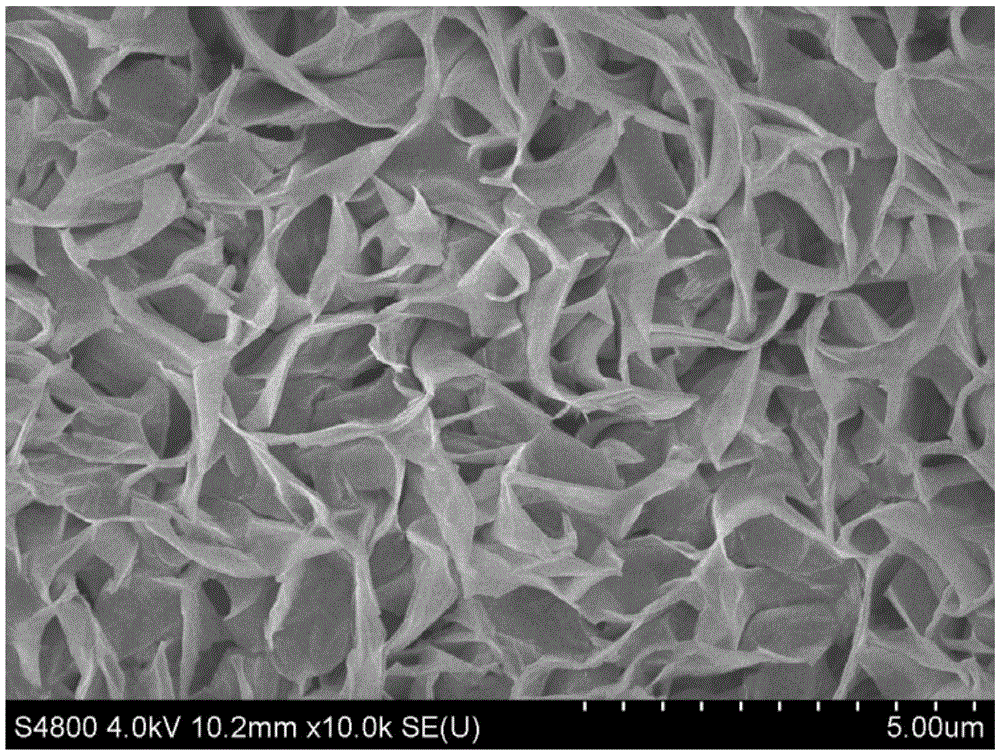

[0043]2. Using an electrochemical workstation, copper foil is used as the cathode, carbon paper is used as the anode, pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com